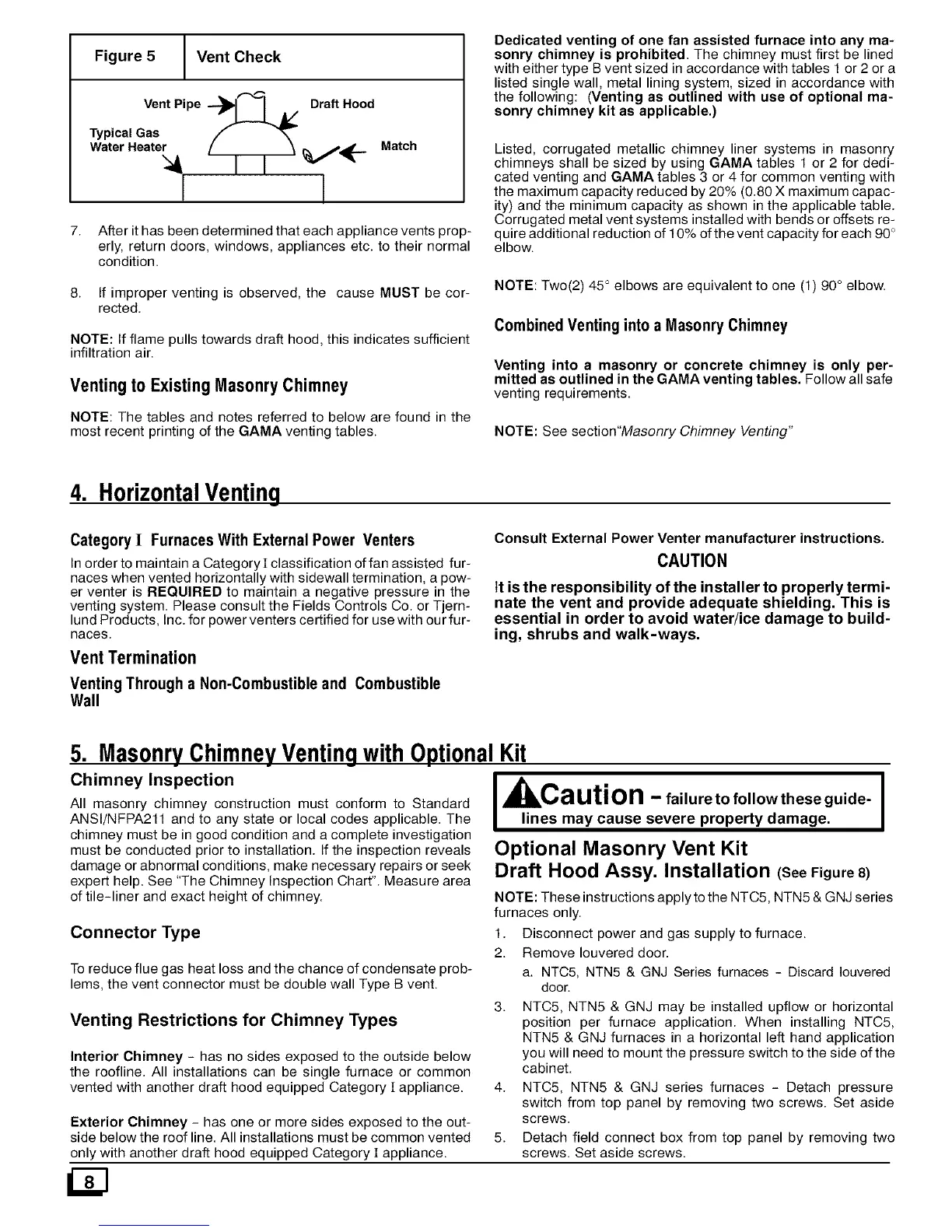

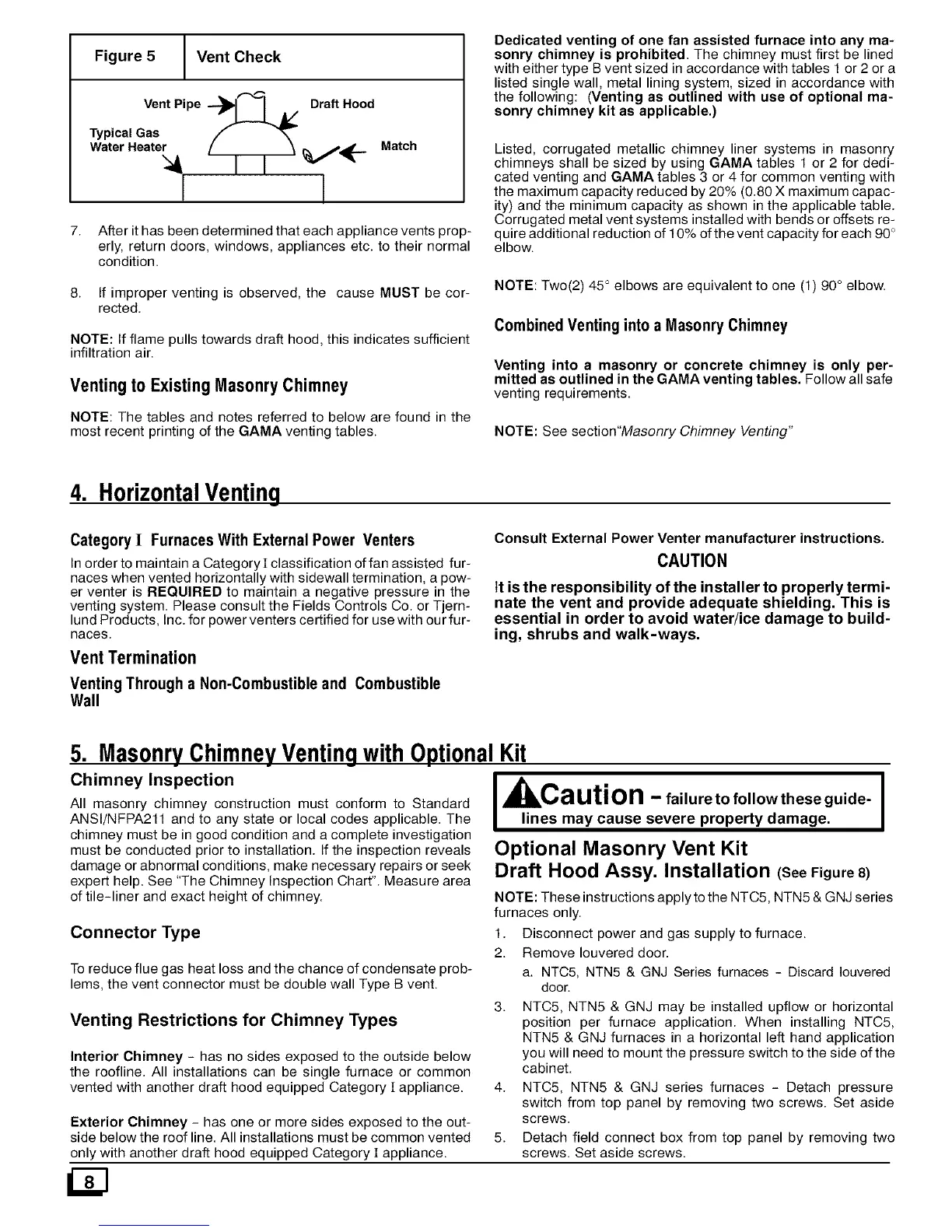

Figure 5 Vent Check

Vent Pipe "-_ I A/ Draft Hood

Typical Gas

Water Heater

! I

Match

7. After it has been determined that each appliance vents prop-

erly, return doors, windows, appliances etc. to their normal

condition.

8. If improper venting is observed, the cause MUST be cor-

rected.

NOTE: If flame pulls towards draft hood, this indicates sufficient

infiltration air.

Venting to ExistingMasonry Chimney

NOTE: The tables and notes referred to below are found in the

most recent printing of the GAMA venting tables.

Dedicated venting of one fan assisted furnace into any ma-

sonry chimney is prohibited. The chimney rnust first be lined

with either type B vent sized in accordance with tables 1 or 2 or a

listed single wall, metal lining system, sized in accordance with

the following: (Venting as outlined with use of optional ma-

sonry chimney kit as applicable.)

Listed, corrugated metallic chimney liner systems in masonry

chimneys shall be sized by using GAMA tables 1 or 2 for dedi-

cated venting and GAMA tables 3 or 4 for common venting with

the maximum capacity reduced by 20% (0.80 X maximum capac-

ity) and the minimum capacity as shown in the applicable table.

Corrugated metal vent systems installed with bends or offsets re-

quire additional reduction of 10% of the vent capacity for each 90°

elbow.

NOTE: Two(2) 45 ° elbows are equivalent to one (1 90° elbow.

Combined Venting into a Masonry Chimney

Venting into a masonry or concrete chimney is only per-

mitted as outlined in the GAMA venting tables. Follow all safe

venting requirernents.

NOTE: See section"Masonry Chimney Venting"

4. HorizontalVenting

Category I Furnaces With External Power Venters

Inorder to maintain a Category][ classification offan assisted fur-

naces when vented horizontally with sidewall termination, a pow-

er venter is REQUIRED to maintain a negative pressure in the

venting system. Please consult the Fields Controls Co. or Tjern-

lund Products, Inc. for power venters certified for use with our fur-

naces.

Vent Termination

Venting Through a Non-Combustible and Combustible

Wall

Consult External Power Venter manufacturer instructions.

CAUTION

It isthe responsibility of the installer to properly termi-

nate the vent and provide adequate shielding. This is

essential in order to avoid water/ice damage to build-

ing, shrubs and walk-ways.

5. MasonryChimneyVentingwithOptionalKit

Chimney Inspection

All masonry chirnney construction must conform to Standard

ANSI/NFPA211 and to any state or local codes applicable. The

chimney must be in good condition and a complete investigation

must be conducted prior to installation. If the inspection reveals

damage or abnormal conditions, make necessary repairs or seek

expert help. See "The Chimney Inspection Chart". Measure area

of tile-liner and exact height of chimney.

Connector Type

To reduce flue gas heat loss and the chance of condensate prob-

lems, the vent connector must be double wall Type B vent.

Venting Restrictions for Chimney Types

Interior Chimney - has no sides exposed to the outside below

the roofline. All installations can be single furnace or common

vented with another draft hood equipped Category ][appliance.

Exterior Chimney - has one or more sides exposed to the out-

side below the roof line. All installations must be common vented

only with another draft hood equipped Category ][appliance.

I, kCa ution - failure to follow these guide- I

lines may cause severe property damage.

Optional Masonry Vent Kit

Draft Hood Assy. Installation (SeeFigure8)

NOTE: These instructions apply to the NTC5, NTN5 & GNJ series

furnaces only.

1. Disconnect power and gas supply to furnace.

2. Remove Iouvered door.

a. NTC5, NTN5 & GNJ Series furnaces - Discard Iouvered

door.

3. NTC5, NTN5 & GNJ may be installed upflow or horizontal

position per furnace application. When installing NTC5,

NTN5 & GNJ furnaces in a horizontal left hand application

you will need to mount the pressure switch to the side of the

cabinet.

4. NTC5, NTN5 & GNJ series furnaces - Detach pressure

switch from top panel by removing two screws. Set aside

screws.

5. Detach field connect box from top panel by removing two

screws. Set aside screws.

Loading...

Loading...