Do you have a question about the ICS Schneider Messtechnik Anton Paar DMA 501 and is the answer not in the manual?

| Measurement Principle | Oscillating U-tube |

|---|---|

| Density Range | 0 g/cm³ to 3 g/cm³ |

| Accuracy | 0.001 g/cm³ |

| Repeatability | 0.0005 g/cm³ |

| Temperature Accuracy | ±0.03 °C |

| Temperature Control | Peltier |

| Sample Volume | 1 mL |

| Interface | RS232, USB |

| Power Supply | 100-240 V, 50/60 Hz |

Document disclaimer regarding responsibilities and regulatory limitations.

Guidelines for proper instrument installation and safe usage procedures.

Essential safety measures for handling substances and operating the instrument.

Safety measures for handling flammable materials near the instrument.

Instructions for safely moving and lifting the instrument.

Procedures and personnel authorized for instrument maintenance and repair.

Legal requirements and considerations for instrument disposal.

Explanation of safety message symbols (Warning, Caution, Notice) used in the document.

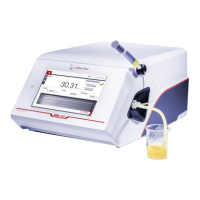

Defines the primary purpose and applications of the DMA 501/1001 density meter.

Details on how to export and print measurement data in various formats.

Lists limitations and excluded measurement types for the instrument.

Identifies and describes the key physical parts and connectors of the instrument.

Specifies the necessary conditions and location for instrument installation.

Step-by-step instructions for physically setting up the instrument.

Guidance on connecting the syringe holder and filling hoses to the instrument.

Steps to verify the integrity of fluid connections to prevent leaks.

Instructions for connecting the waste disposal system.

Guidance on connecting the air pump hose for drying functions.

Details on connecting the instrument to a power source safely.

Procedure for powering the instrument on and off.

Steps to verify instrument accuracy and condition after installation.

Process for verifying the instrument's software code integrity during startup.

Setting the user interface language, number, and date formats.

Steps to set the instrument's internal clock and time zone.

How to adjust the screen brightness for optimal visibility.

Configuring the camera for visual inspection of the measuring cell.

Selecting default units for density and temperature measurements.

Customizing and saving measurement parameters for specific products.

Setting up visual displays for real-time measurement monitoring.

Defining how measurement results are presented in reports.

Introduction to key parameters that influence measurement results.

Specifying the desired temperature for the measurement.

Selecting the trade-off between measurement speed and accuracy.

Enabling or disabling the check for stable density and temperature values.

Setting a delay after stability criteria are met before recording the result.

Defining the maximum time before an incomplete measurement is aborted.

Automatic detection of air bubbles during sample filling.

Information on additional parameters available with optional features.

Overview of the standard procedure for conducting a measurement.

Initiating a measurement, either with a predefined product or on-the-fly.

Methods and considerations for introducing the sample into the measuring cell.

Specifying the volume of sample needed for accurate measurements.

Using FillingCheck™™ and U-View™™ for visual bubble detection.

Detailed steps for filling the sample using a syringe.

Instructions for using the optional peristaltic pump for sample filling.

Steps to start, monitor, and complete a measurement.

Accessing, exporting, and managing saved measurement data.

Methods for removing dissolved gases from liquid samples.

Techniques for handling challenging sample types like viscous liquids or pastes.

Procedures for verifying the instrument's performance and accuracy.

Troubleshooting steps when a water check fails.

Steps to calibrate the instrument using known standards.

Specific procedures for air/water and wide-range density adjustments.

Procedure to revert instrument adjustments to their default factory state.

Information and procedures related to instrument calibration beyond adjustments.

Detailed steps for cleaning and drying the critical measuring cell.

Guidelines on when to clean and recommended cleaning agents.

Step-by-step instructions for the measuring cell cleaning process.

Methods for cleaning the external parts of the instrument.

Recommendations for storing the instrument when not in use.

Information on periodic maintenance and optional services.

Process for contacting representatives for instrument repair.

Detailed technical specifications including measuring ranges and accuracy.

Environmental, electrical, and physical data for the instrument.

Lists materials in contact with samples and housing materials.

Formal statement of compliance with EU directives and applied standards.