ICS, Blount Inc. • 4909 SE International Way Portland, OR 97222 USA • Ph 800.321.1240 • Fax 503.653.4393 icsbestway.com

© Copyright 2008 ICS, Blount Inc. Specifications subject to change without notice. All rights reserved. ICS, WallWalker, Redzaw, SpeedHook and SealPro are registered trademarks of ICS, Blount Inc. The best way to cut concrete,

Bestway, ProFORCE, PremiumPRO, TwinPRO, AbrasivePRO, SoftPRO, SpeedPRO, CornerPRO, PRK, TSS, Diamond Chain Technology, DCT, TwinMAX and FORCE4 are trademarks of ICS, Blount Inc. 1108

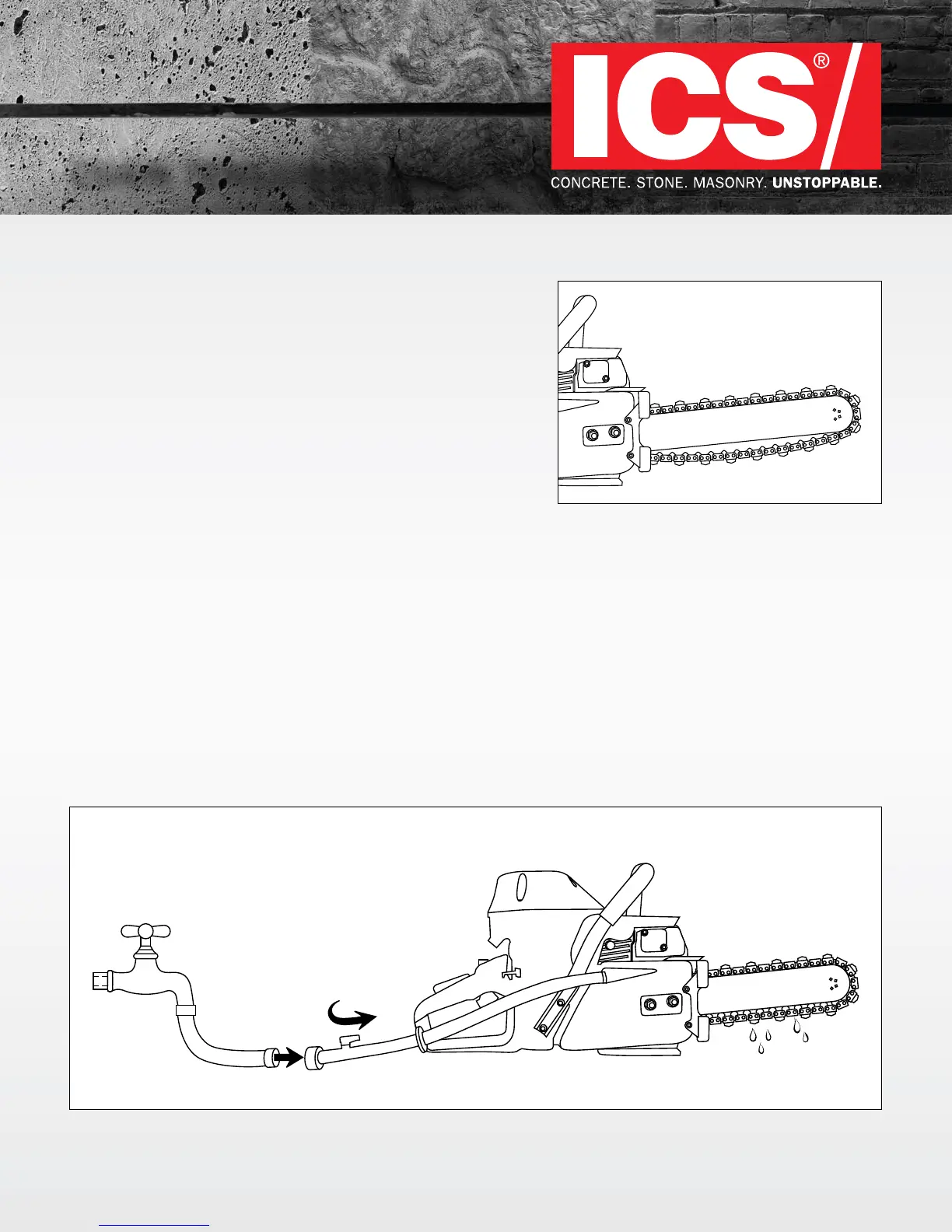

ADDITIONAL TENSIONING TIPS:

1. To reduce chain stretch and tensioning downtime, use 20 psi (1.5 bar) or greater water pressure.

2. Oil the chain at the end of the day to prevent rust but be careful not to over tension in this condition.

3. When pulling the chain around the bar by hand, be careful not to touch the bar with thumb or forefinger. The bar rails can be

very sharp. Grab only the diamond segments to pull the chain.

4. Always pull the chain away from the WallWalker

®

. The point of the WallWalker

®

can also be very sharp.

5. Always turn the engine off before tensioning the chain.

ADDITIONAL INFORMATION

Concrete cutting chainsaws operate with looser chain tension than wood

chainsaws. It is common, especially on gas powered, concrete cutting

chainsaws to have the drive links hang completely out of the bar. Wood

cutting chainsaws use oil to lubricate the chain. The oil makes the chain

very slippery and allows the drive links to fully nest between the teeth of

the drive sprocket. Concrete cutting chainsaws require water for cooling

and flushing the cut. Water is not as good as oil as a lubricant. Also, there

are concrete particles mixed in with the water. As a result, sometimes the

drive links do not nest properly on the drive sprocket. When this happens,

the chain acts like it got tighter. There seems to be tight spots and loose

spots as you pull the chain around the bar. If you tension when the chain

is in one of the loose spots, it will be too tight at some point in it’s rotation

around the bar. Rotating the chain completely around the bar by hand will

let you know you have the chain properly tensioned.

CHAIN TENSIONING

Loading...

Loading...