IMER INTERNATIONAL S.p.A.

H110VF - H110VR

31

8.1. Cutting wedges

To cut wedge shapes, use the workpiece guide square as

shown in Þ gure 8-A.

9. Lower guard

The part of the blade that projects below the table is protect-

ed by a steel guard, which has the dual function of prevent-

ing contact with the tool and drive components, and acting

as a chip extractor.

This cover must be removed with the machine stopped

and disconnected from the electrical power supply, through

a simple control: 1) undo the bolt [S] (Þ g.7); 2) remove the

guard [T] (Þ g.7) by pulling it horizontally towards you.

With the guard removed, it is possible to replace the cutting

disc and the drive belts.

On completion of these operations, reÞ t the guard [T]

(Þ g.7) in its original position and secure it with the bolt [S]

(Þ g.7).

10. Replacing the cutting disc

The sawing machine was designed for use exclusively with

cutting discs with the speciÞ cations set out in Table 1.

The choice and state of maintenance of the blades affect

the level of noise to which the operator is exposed.

Use the original IMER spare part, which can be ordered with

code 3223136, or tools that meet EN Std. 847-1.

Stop the machine and unplug it from the power supply,

remove the lower guard as described in point 9, and then

proceed as follows, using only tools that comply with EN

standard 847-1: 1) immobilise the disc spindle by inserting

the split pin [16] (Þ g.1) supplied with the machine, in the hole

[U] (Þ g.8); 2) unscrew the nut [V] (Þ g.8) by turning it clock-

wise, and remove the front ß ange; 3) remove the cutting disc

and replace it with a new one; 4) reÞ t the front ß ange and Þ x

by Þ rmly tightening nut [V] (Þ g.8); 5) reÞ t the lower guard [T]

(Þ g.7).

Remember to remove the locking split pin from the hole

[U] (Þ g.8), before restarting the machine.

11. Adjusting and replacing the drive belts

Stop the machine and unplug it from the power supply,

remove the lower guard as described in point 9, and then

proceed as follows, using only tools that comply with EN

standard 847-1: 1) immobilise the disc spindle by inserting

the split pin [16) (Þ g.1) supplied with the machine, in the hole

[U] (Þ g.8); 2) unscrew the nut [V] (Þ g.8) by turning it clock-

wise, and remove the front ß ange; 3) remove the cutting

disc; 4) carefully loosen, without unscrewing completely

(maximum 2 turns) the bolts [W] and the fulcrum [Z] (Þ g.8), to

adjust the tension of the drive belts and, if necessary, pro-

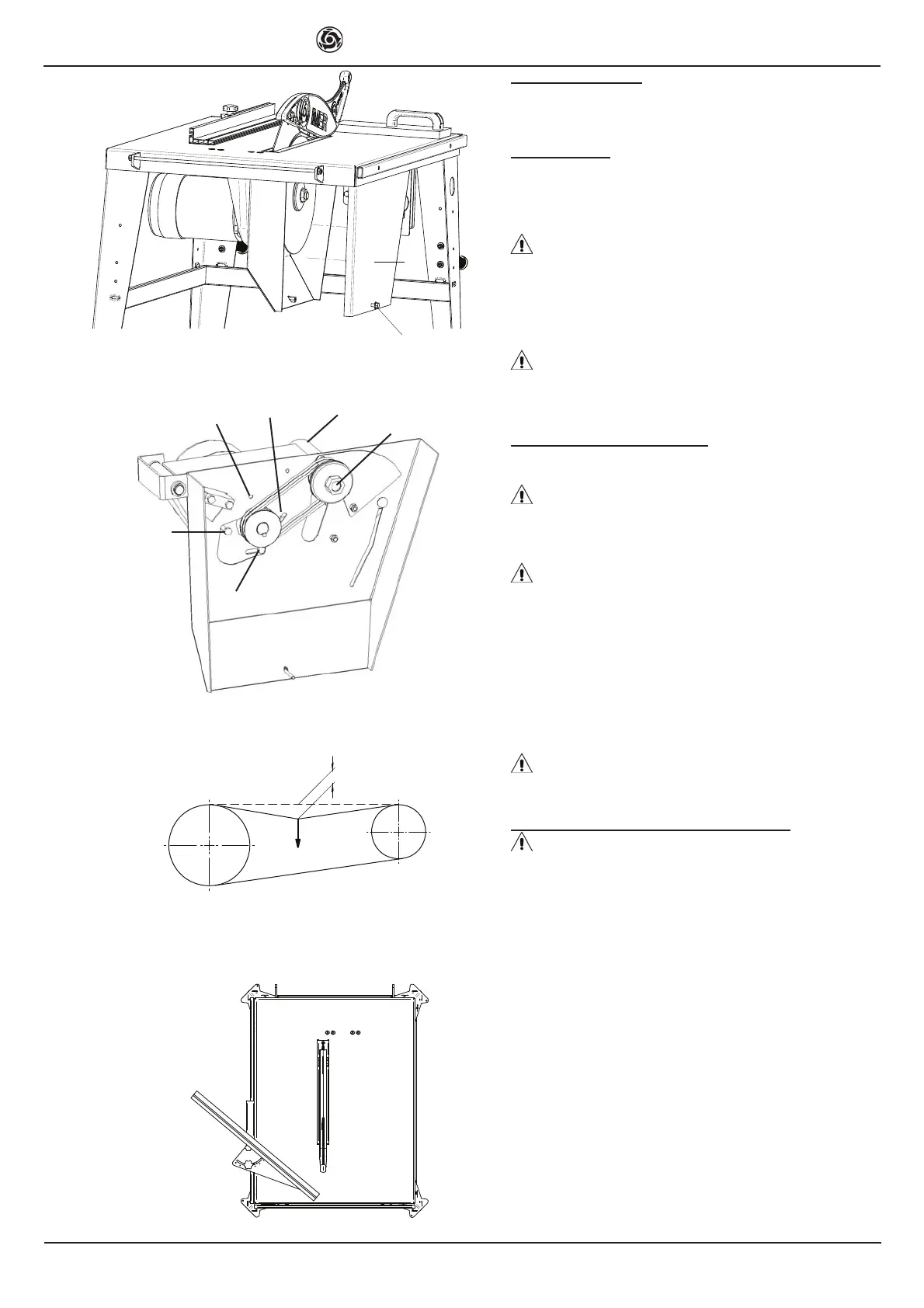

ceed with replacement; if the belt tension is correct, applying

a force of about F=6 Kg to the centre of the free section of

belt, the camber should be approx. f=6 mm (diagram A); 5)

reassemble in the reverse order of disassembly, taking care

to tighten the bolt [V] properly and to remove the locking split

pin from the hole [U] before restarting the machine.

GB

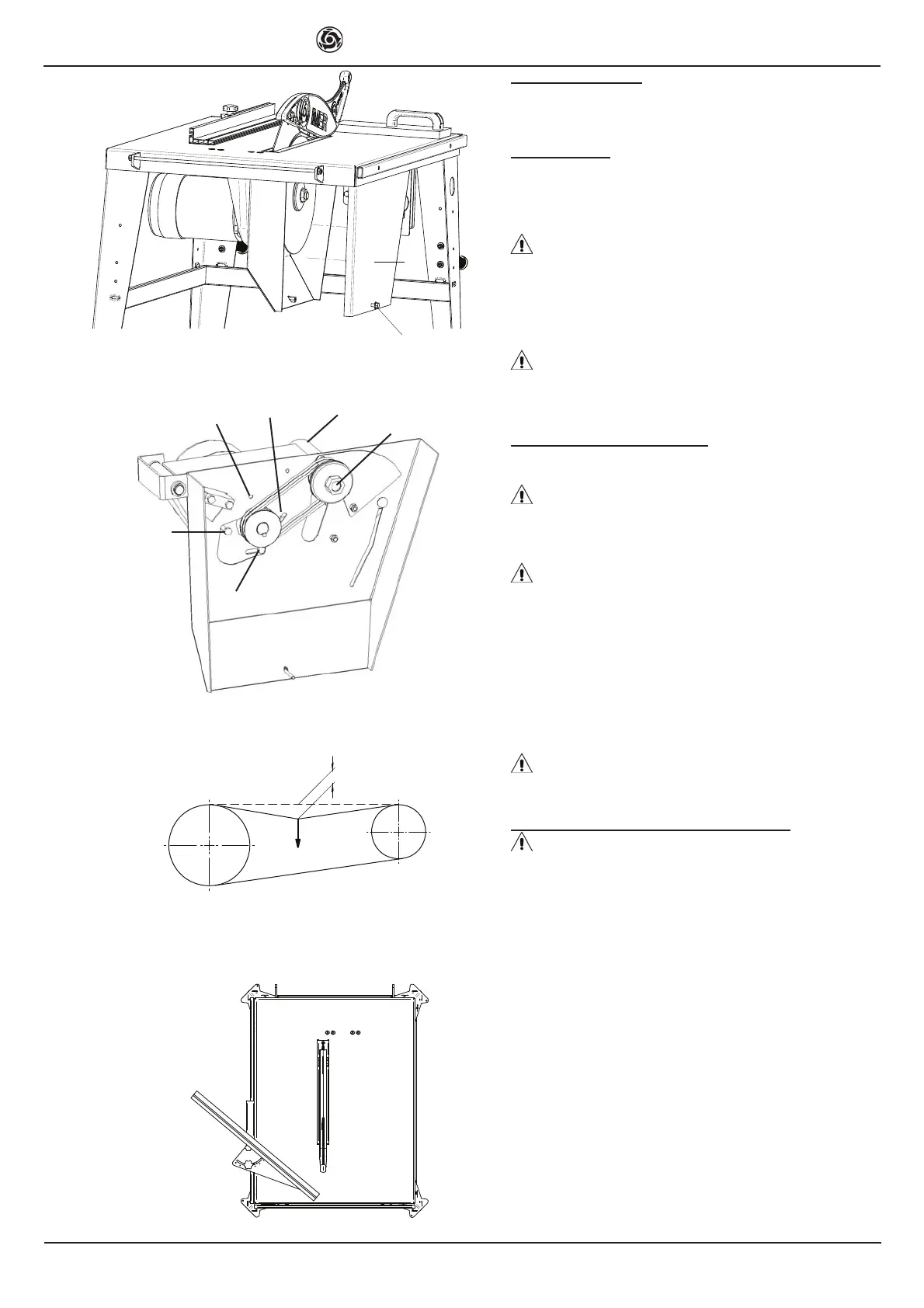

Fig. 8

V

U

W

W

W

Z

Fig. 7

F

f

Diagram A

4

3

TAGLIO INCLINATO O CUNEO

Fig. 8-A

Loading...

Loading...