30

IMER INTERNATIONAL S.p.A.

KOINE 3

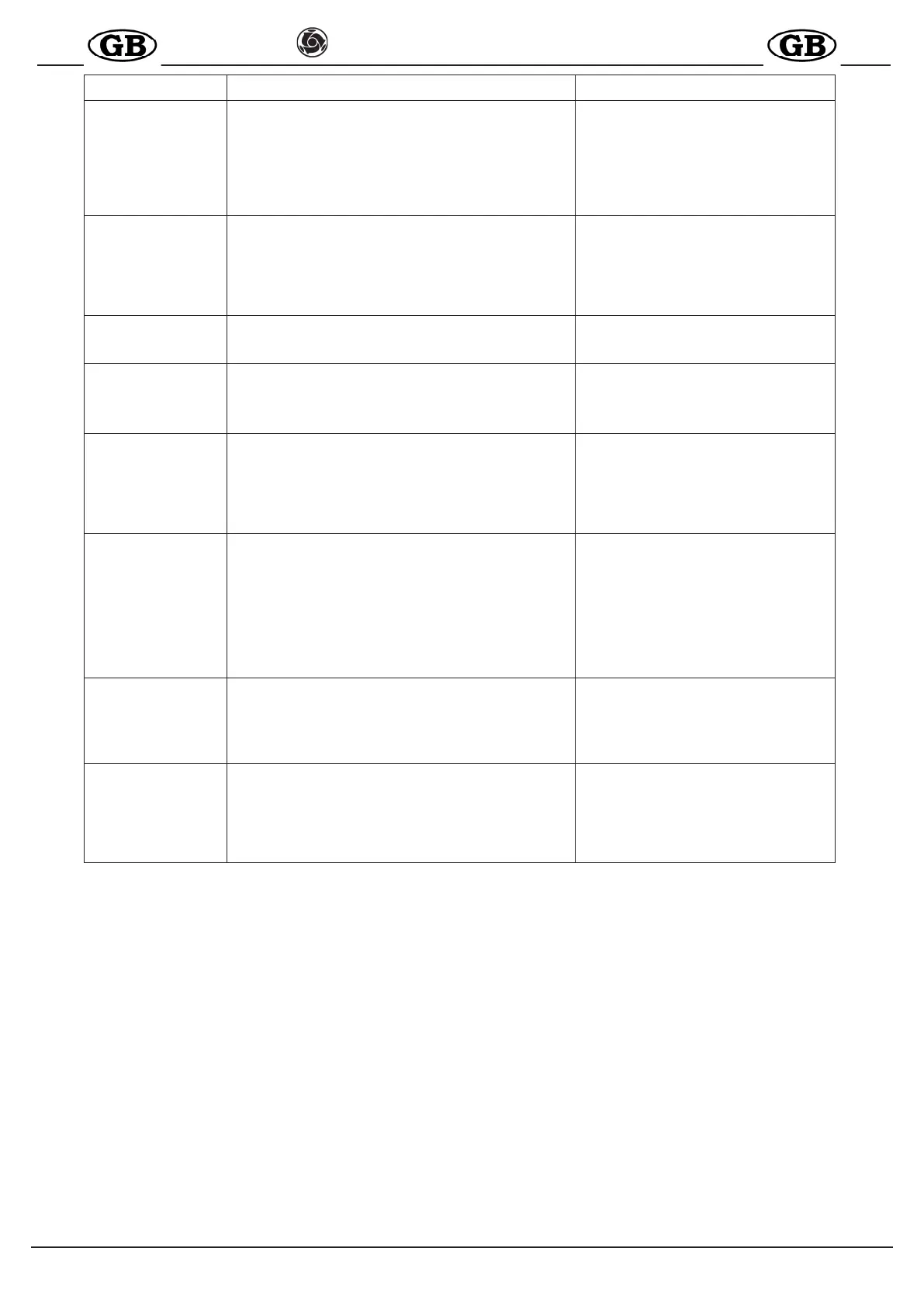

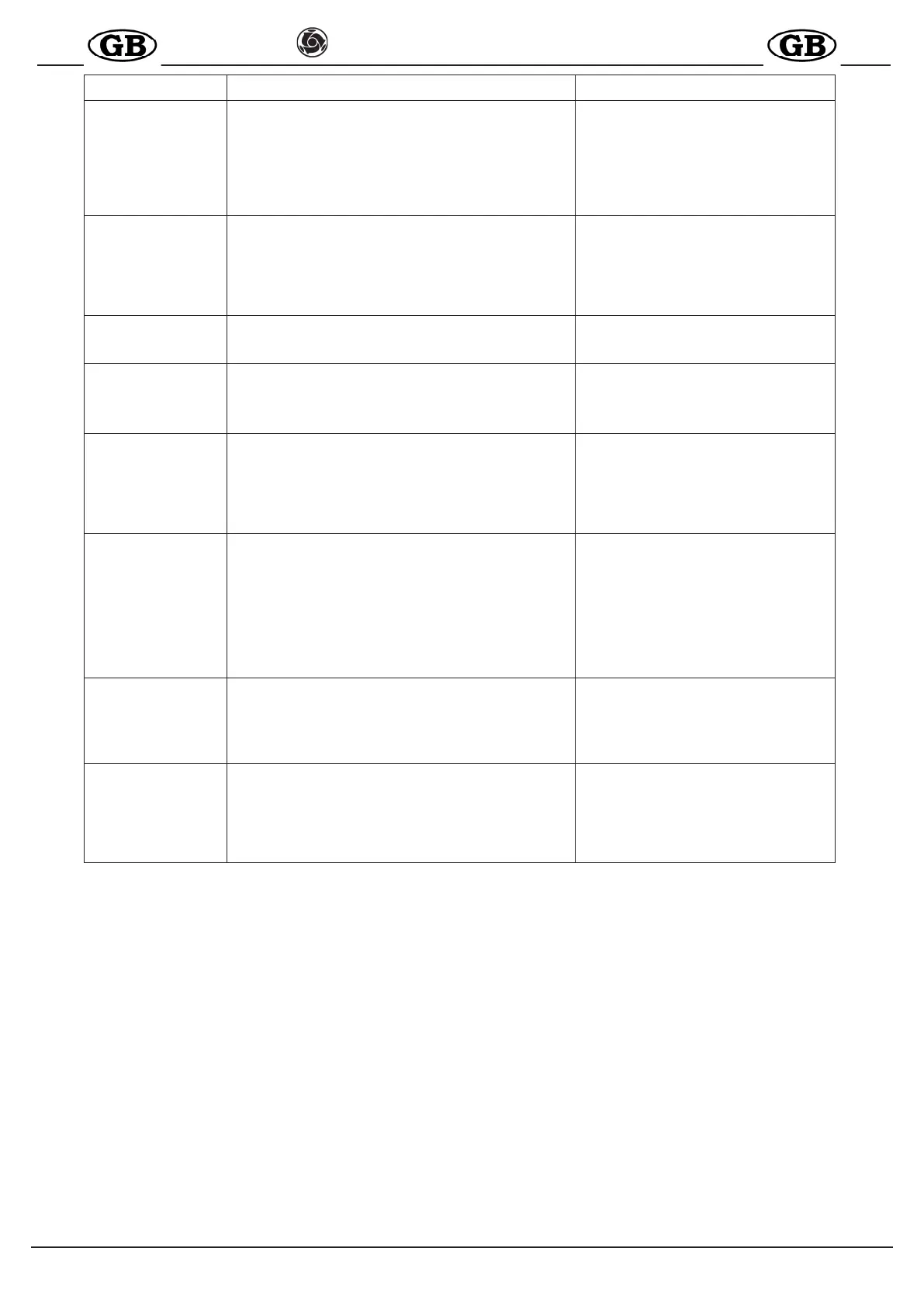

INCONVENIENTI CAUSE RIMEDI

Machine does not start Water

Water pressure too low: the gauge shows pressure below 2 bar

(green lamp on?), the display shows the text H

2

O

- Check that water is delivered from the supply

hose

- Check that the water lter is clean

- Check that the water pump is switched on

- If the pump collects from a tank, check that it has

been primed and there are

no leaks from couplings

Machine does not start Material

- Product too dry in mixing chamber

(mortar pump seized? red lamp on?)

- Initial start-up not performed correctly (see

para.11)

- Water ow rate setting too low (see para.11)

- No water delivered to mixing chamber

(water inlet obstructed, water solenoid valve

malfunction)

Machine does not start Grid

-Grid not inserted completely, the display shows the text Bloc

-Check that the grid is positioned correctly

Machine does not start Air

- The air pressure, with jet valve completely open, does not fall

below the minimum pressure value on the machine pressure switch

(table 1)

- Check that the air hose is not bent or obstructe-

do

- Check that the jet nozzle is perfectly clean

Machine does not start

and compressor does

not start and the blue

light is OFF

Electrical current

- No current delivered to connector of site panel

(fuses?)

- No power delivered to machine

(defective connector connection? loose cable?)

- Main switch not ON

- Check points listed alongside

Machine does not start

but compressor starts

Electrical current

- Start selector switch not in correct position

- Mixing chamber open

(start/stop pushbutton lamp on?)

- Mortar pump motor connector not inserted

(start/stop pushbutton lamp on?)

- Low water pressure switch trips on start-up

(water pump switched on ?see also "machine does not start due to

water)

- Check points listed alongside

Machine does not stop

and/or compressor

does not stop

Air

- Air hose defective

(hose cut? Air leaks from couplings?

- Compressor air supply low

- Jet air valve faulty (blocked in open position)

- Check the air hose and couplings in particular

and replace if necessary

- Check air lter (see para. 12)

- Check compressor relief valve

Machine stops after

starting up

Water

- Intake lter clogged

- Pressure reducer lter clogged

- Water hose too long and/or too narrow

- Water supply insufcient

- Check points listed alongside: clean lters,

check for adequate ow rate from the water hose

(at least 10-12 l/min if working with lime-cement

based plaster, at least 15-20 l/min with gypsum

based plasters) and replace hose if necessary or

collect water from an auxiliary tank

Loading...

Loading...