,0(5,17(51$7,21$/6S$

MORTARMAN 120 PLUS

Dear Customer,

compliments on your purchase: this IMER mixer, the result of long-stan-

ding experience in the fi eld, features maximum reliability and innovative

technical solutions.

- WORKING IN SAFETY

To work in complete safety, read the following instructions careful-

ly before using the machine.

This OPERATION AND MAINTENANCE manual must be kept by the

Site Manager and be always available for consultation.

The manual is considered part of the machine and must be stored for

future reference (EN 12100-2) through to scrapping of the machine it-

self. Should the manual be lost or damaged, a replacement copy can be

ordered from the manufacturer.

The manual contains important information regarding site preparation,

machine use, maintenance procedures, and requests for spare parts.

Nevertheless, the installer and the operator must both have adequate

experience and knowledge of the machine prior to use.

In order to ensure operator safety, safe operation and long service life,

it is imperative to adhere to the instructions set out herein and the re-

quirements of the legislation in force governing safety in the workplace.

Use individual safety equipment (suitable shoes and clothing, gloves,

safety glasses, etc.).

- Make sure that all signs are legible.

- It is strictly forbidden to carry out any form of modifi cation to

the steel structure or working parts of the mixer.

IMER INTERNATIONAL accepts no liability for failure to comply with

laws governing the use of this type of equipment, with particular refe-

rence to: improper use, incorrect power supply, lack of maintenance,

unauthorised modi cations, failure to comply, either wholly or partially,

with the instructions set out in this manual.

IMER INTERNATIONAL reserves the right to modify features of the mi-

xer and contents of this manual, without the obligation to update pre-

vious machines and/or manuals.

1. TECHNICAL DATA

Technical data are stated in table 1 and electrical speci cations in table

2.

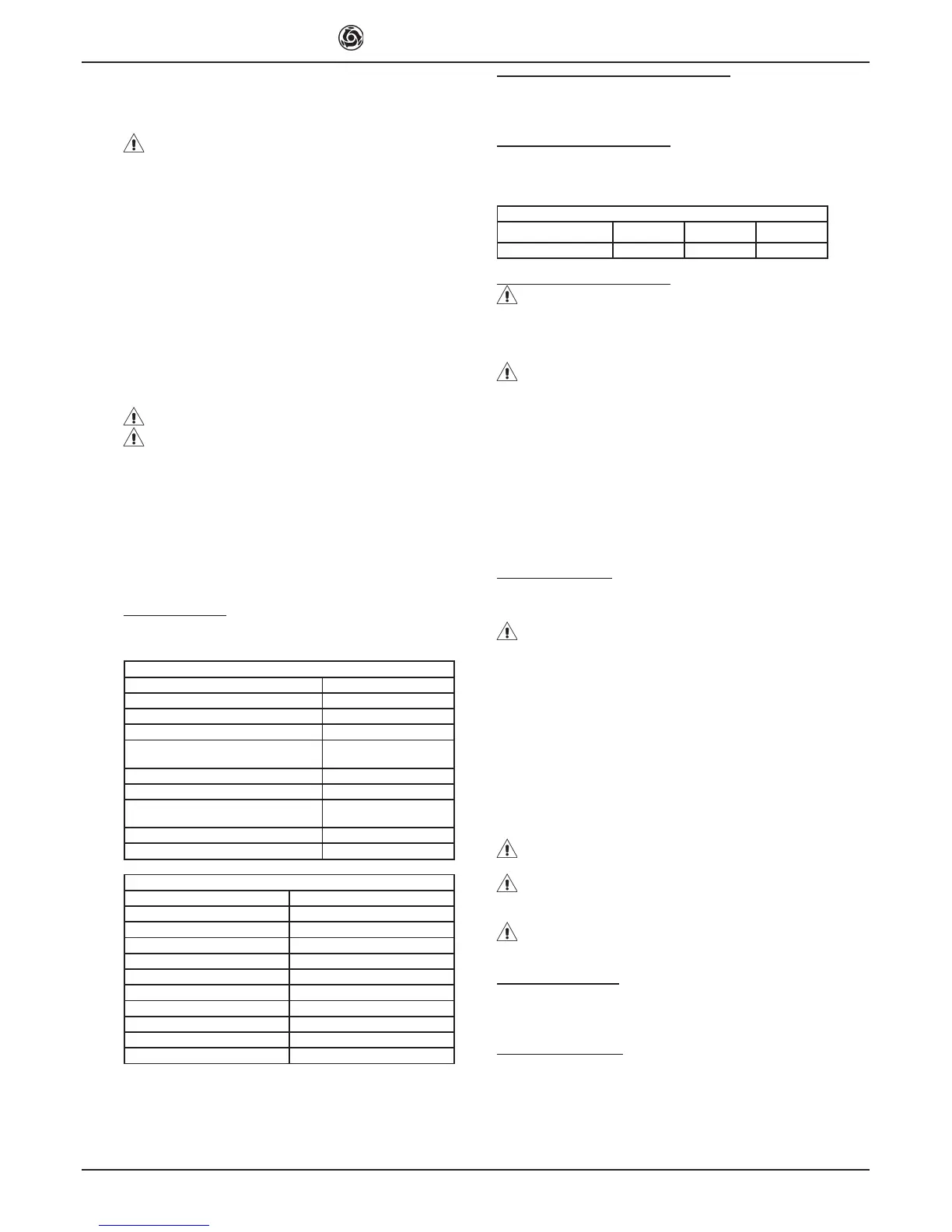

7DEOH7(&+1,&$/'$7$

0RGHO 0257$50$13/86

Drum capacity 120 l

Mix capacity (approx.)0 l

Paddle rpm 38 Rpm

Paddle rotation direction

(view from loading mouth)

Clockwise

Wheel dimensions 300 mm

Single phase 115V/60Hz motor power 1.4 kW

Overall dimensions

(width x length x height)

780x880x1000 mm

Machine weight 130 Kg

Weight with packaging 139 Kg

7DEOH

)HDWXUH 0RWRU9+]

Power (kW) 1.4

Rated voltage (V) 115

Frequency (Hz) 60

Absorbed current (A) 14.5

Number of poles 2

rpm 2800

Service type S1

Insulation category F

Protection category IP55

Capacitor (F) 100 (Ø 50x120)

2. DESIGN AND CONSTRUCTION STANDARDS

The MORTARMAN 120 PLUS mixer is designed and constructed in line

with the following harmonized standards: EN 12151:2008; EN 12100-

1/2:2005; EN 60204-1:2006.

3. NOISE LEVEL AND VIBRATIONS

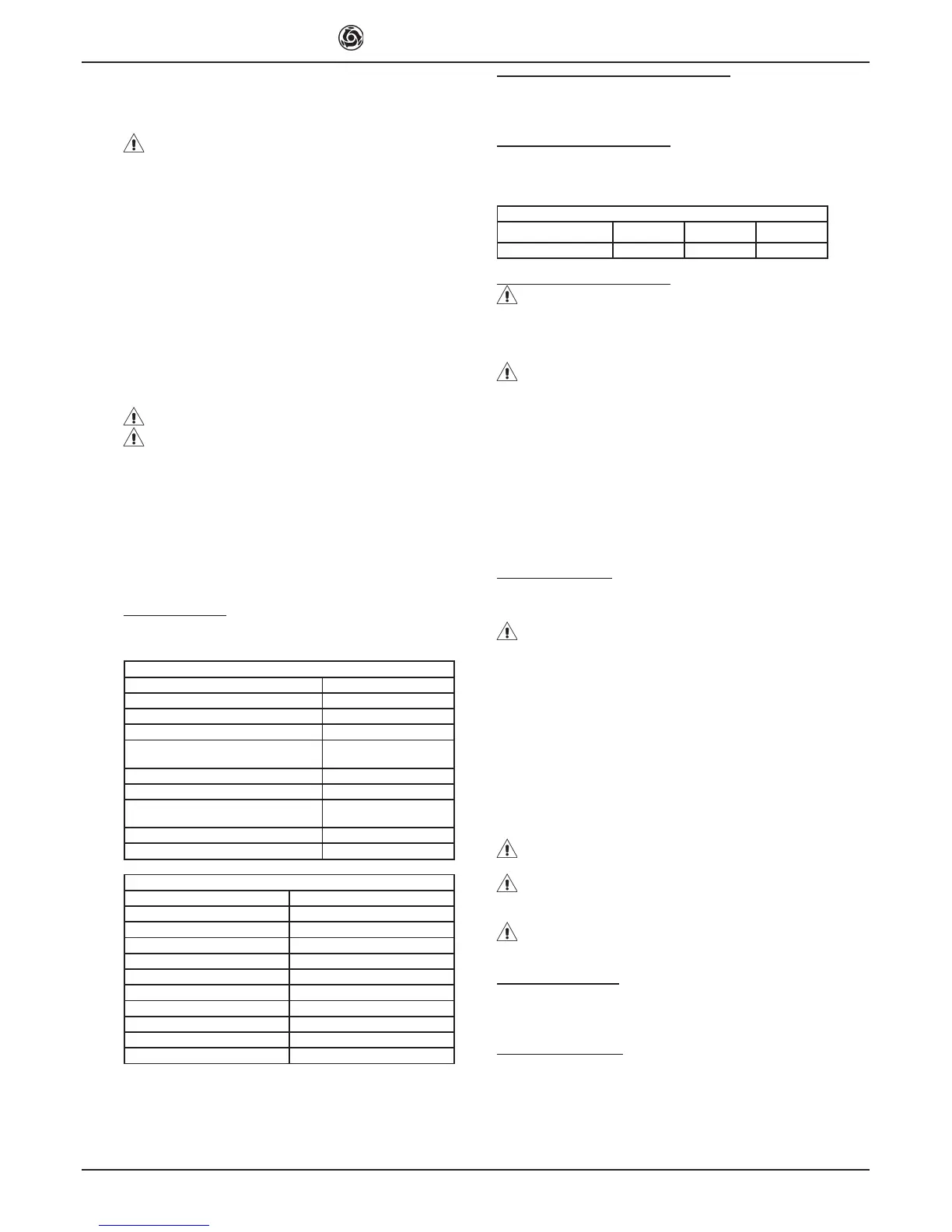

Table 3 gives the sound pressure level of the machine measured at the

ear of the operator when running empty (LPA) and vibrations transmitted

when it is operating.

7DEOH

0RGHO 7\SHRIPRWRU /

S$

$

HT

MORTARMAN 120 PLUS Electric 70 dB 2 m/s

2

4. DESCRIPTION AND OPERATION

- The mixer is intended for use on construction sites for

mixing a wide range of fi ne grained materials, both wet and dry,

premixed in bags or drawn from silos, of low and high viscosity

(mortar, paints, plaster, cement, adhesives, resins, coatings, vibra-

tion-damping materials, insulation).

- Do not use the machine in environments subject to tempe-

ratures below 0° C.

The mixer is composed of a frame (ref.1, g.1) which supports the mi-

xing tank (ref.2, g.1).

The tank mounts the gear reducer (ref.6, g.1) driven by the motor (ref.5,

g.1) via a poly-V drive belt.

The reducer’s output shaft delivers the drive to the mixer head).

The tank can be emptied by opening the outlet (ref.7, g.1) by hand.

The motor is started and stopped with the switch on the electrical cabi-

net (ref.8, g.1).

The electrical cabinet has a plug (ref.9, g.1) for connecting to the elec-

tric power supply.

5. SAFETY MEASURES

The IMER mixer is designed to operate on construction sites and is not

equipped with its own lighting; the work site must be well illuminated

(min. 300 lux).

- Never use the machine in areas at risk of explosion/fi res.

7KH,0(5PL[HUZLOORQO\UXQLIDOOLWVVDIHW\GHYLFHVDUHLQSODFH

DQGLQSHUIHFWFRQGLWLRQ

'RQRWXVHLPSURYLVHGDQGRUGHIHFWLYHSRZHUVXSSO\OLQHV

7KHFRQQHFWLRQOLQHVRQWKHVLWHPXVWEHODLGLQVXFKDZD\WKDW

WKH\FDQQRWEHGDPDJHG1HYHUVWDQGWKHPL[HURQLWVSRZHUVXS

SO\FDEOH

7KHSOXJVRFNHWFRQQHFWLRQVPXVWEHSURWHFWHGIURPZDWHU

8VHRQO\FRQQHFWRUVHTXLSSHGZLWKSURWHFWLRQDJDLQVWZDWHUMHWV

,3

5HSDLUVWRWKHHOHFWULFDOLQVWDOODWLRQPXVWEHSHUIRUPHGH[FOX

VLYHO\E\VSHFLDOLVHGSHUVRQQHO'RQRWPDNHDQ\DGMXVWPHQWVRU

FDUU\RXWDQ\PDLQWHQDQFHZRUNZKLOHWKHPDFKLQHLVSRZHUHGXS

RUUXQQLQJ

- Never put your hands or tools into the tank while the machine

is running.

- Take care, when handling mix components, not to raise dust

which may be inhaled. If this is not possible, masks must be worn

to protect the mouth and nose.

- To stop the mixer, use the switch (ref.8, fi g.1). Do not attempt

to stop the mixer in any other manner.

6. ELECTRICAL SAFETY

The IMER mixer is constructed in line with the provisions of EN 60204-1,

and is protected against jets of water (IP 55) and equipped with protec-

tions against overloads and automatic restarting after power failures.

7. MECHANICAL SAFETY

The hazardous points on the IMER mixer are protected by means of

safety devices, which must remain tted at all times and kept in perfect

condition - as, for instance, the drive belt guard.

The tank is tted with a guard which enables mix components to be loa-

ded into it while preventing access to the mixing area (ref.10, g.1).

The machine is equipped with an electrical safety (interlock) which pre-

vents it from running when the mixer tank guard is open.

ORIGINAL INSTRUCTIONS

Loading...

Loading...