PPI-2 REV. J IMPCO Technologies Inc November, 2014

3030 South Susan St. Page 8 of 16

Santa Ana, CA 92704

www.impcotechnologies.com

3030 S Susan Street, Santa Ana, CA 92704

Ph: +1 714 656 1200 Fax: +1 714 656 1400

19. Deposits may accumulate from the use of hard

water. This condition can be alleviated through

the use of radiator additives or permanent

antifreeze solutions. Remove any accumulation

with a wire brush before assembly. Steel water

inlet and outlet fittings may cause erosion from

electrolysis. Use brass or plastic water fittings

only.

REASSEMBLY OF REGULATOR

• Carefully clean and inspect all metal parts; springs, levers, pivot pins and screws. Replace all parts

that are included in the repair kits.

• Carefully clean the body casting and inspect all sealing surfaces . Wipe with a clean rag. Inspect

the primary section for foreign materials that might loosen and damage the soft face valves.

• Clear out the inlet and outlet passages with compressed air. Be sure no foreign material remains in

these passages.

• Inspect the primary orifice and the secondary orifice for nicks, scratches or uneven wear.

IMPORTANT!

If the primary or secondary seats show any of the above mentioned conditions, the regulator is not

rebuildable and must be replaced.

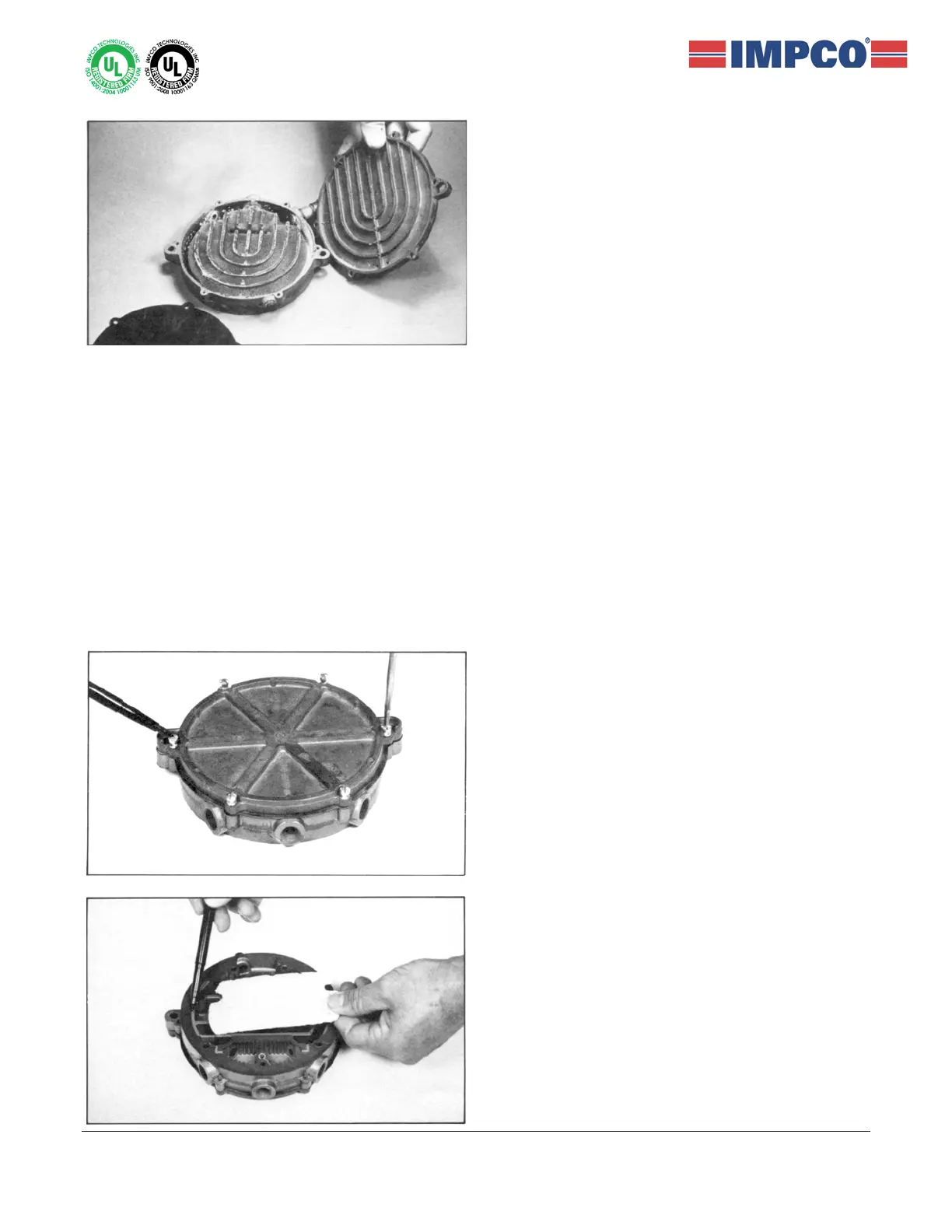

20. Reassemble the back cover (22) and gasket (21)

to the heat exchanger body (19). Replace six

screws (2). Match the mounting bosses in the

cover with those on the heat exchanger. Tighten

the two screws shown in the photo first, then

upper and lower screws diagonally opposite to

draw the cover down evenly. Torque to 25-35 in-

lbs (2.8-4.0 Nm).

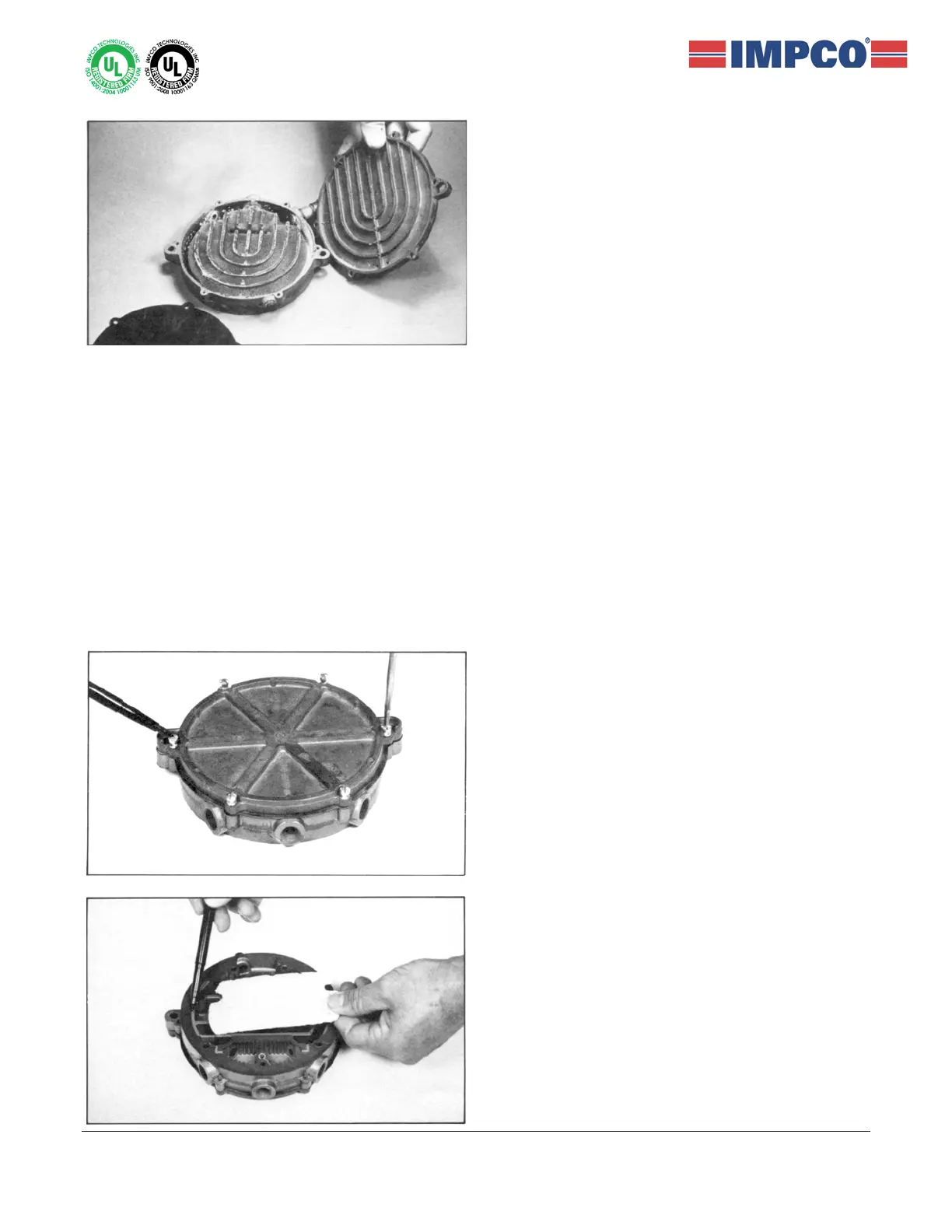

21. The pen indicates the recess cast in the body

(19) to retain the sponge (17). Be sure to

accurately install the sponge in the recess.

Loading...

Loading...