13

CA-3 & DA-3 POT AND PAN WASHERS

MAINTENANCE REQUIREMENTS

This section is intended for qualied service and/or

maintenance technicians.

The following maintenance should be conducted

quarterly:

1. Remove and clean the strainer screens on water

and steam lines. If the screens cannot be cleaned,

replace.

2. Inspect the condition of the ll solenoid valve seats

and diaphragms. Replace as necessary.

3. Inspect drain 0-Rings for leakage. Replace where

necessary.

4. Check door spring tension and adjust where

necessary.

5. Check wash and rinse hub bushing/bearing and

replace where necessary.

MAINTENANCE PROCEDURES

Solenoid Valve Disassembly (SK-5825)

1. Disconnect the power supply to the machine.

2. Turn o the water supply.

3. Remove cap on top of the coil. Remove the coil.

4. Remove the 4 hex bolts and lift bonnet from valve

body. Note positioning of spring and plunger.

5. Remove main piston.

6. Inspect for dirt, wear or lime build-up. Clean or

replace as required.

7. Reassemble in reverse of disassembly.

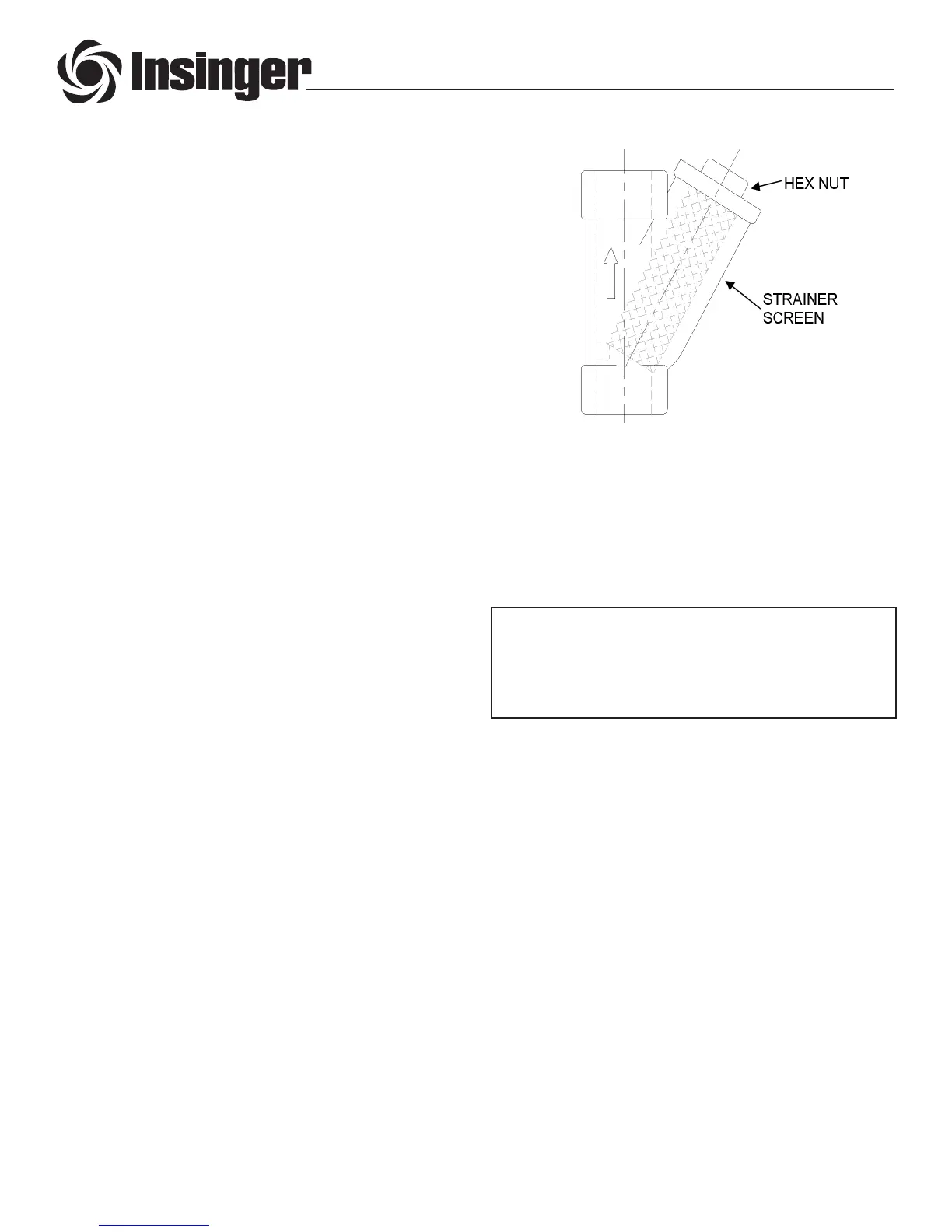

Line Strainer Disassembly

1. Shut o water supply.

2. Remove large hex nut on bottom of strainer body.

3. Remove strainer screen. Inspect and clean or

replace as necessary.

4. Reassemble in reverse of disassembly. Water ow

must be same direction as arrow on line strainer

body. Use new gaskets to insure a tight seal.

Pump Disassembly

1. Before disassembling pump ensure there are no

obstructions in the pump intake by removing and

cleaning the suction strainer (inside tank).

PART 5 MAINTENANCE & REPAIR PROCEDURES

®

CA-3 & DA-3 Technical Manual 2018 www.insingermachine.com 800-344-4802

2. Remove the pump motor and impeller adaptor by

removing the 4 hex bolts attaching them to the

pump housing.

3. Repair or replace the pump parts as required.

4. Reassemble in reverse of disassembly.

Wash and Rinse Cycle

1. The timing sequence consists of two timers.

2. The CA-3, CA-3C, and DA-3 use a ve minute

timer adjusted to 120 seconds for the wash cycle

(P/N DE7-28)

3. They also use a one minute timer adjusted to 15

seconds for the rinse (P/N DE7-27).

4. Should either of these become defective, replace.

NOTE:

It is not necessary to remove the

pump housing from the machine to

disassemble the pump.

Line Strainer Assembly

Loading...

Loading...