12

PART 4 CLEANING INSTRUCTIONS

®

CA-3 & DA-3 POT AND PAN WASHERS

CLEANING INSTRUCTIONS

DAILY CLEANING

The following cleaning procedures should be done

daily, at the end of the shift:

1. Remove all internal removable parts including

rotating spray pipes, scrap screens, drain overow

tubes, suction strainers and curtains.

2. Remove the end caps from the spray manifolds

and clean with the brush provided. Flush the

manifolds.

!

CA-3 & DA-3 Technical Manual 2018 www.insingermachine.com 800-344-4802

CAUTION:

V-cup seal on the drain overow tube may become

gummed which will not allow the overow tube to

seat properly. This will cause the drain to leak water.

Remove any build-up on the V-cup seal. When the

seal becomes worn, replace.

3. Flush scrap screens of matter.

4. Clean drain overow tube.

5. Clean suction strainers of build-up.

CAUTION:

Improper cleaning of suction strainers will cause

the pumps to cavitate. This will cause poor washing

results.

7. Rinse nozzles should be cleaned of matter.

8. Doors should be left open to allow drying of interior

surfaces.

WEEKLY CLEANING

1. The entire machine should be wiped down using

an industrial grade stainless steel cleaner.

2. Under the supervision of your detergent supplier

the machine interior must be properly de-limed.

3. The switch on the control panel labelled MANUAL

and the switch labelled WASH should be used

when de-liming the machine. When activated,

these switches keep the machine in an indenite

wash cycle. This feature can also be used to wash

heavily soiled ware.

NOTE:

The water quality in some areas

requires de-liming to be done more

frequently. Contact your detergent

supplier for recommended de-liming

frequency.

CAUTION:

Do not remove wash and rinse spray arms from the

hubs as these are factory set. Cleaning should be

done by removing the endcap on each arm.

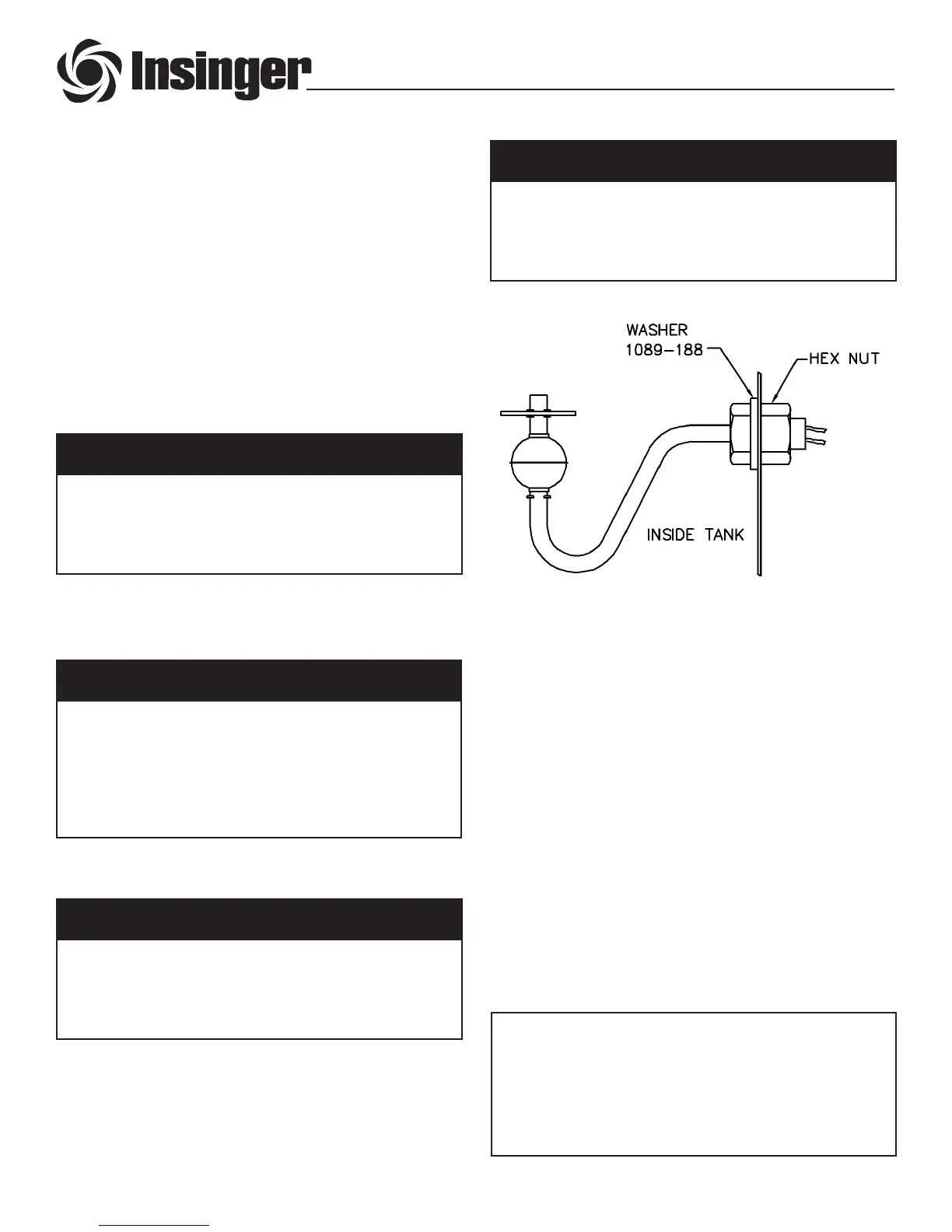

6. Clean tank level oats (1 per tank) with a plastic

abrasive pad. DO NOT use steel wool.

DE5-60: Liquid Level Float

CAUTION:

Level oats must be cleaned daily. Build-up of

grease and scum will cause faulty operation of tank

ll and heating system.

Loading...

Loading...