English

- 27 -

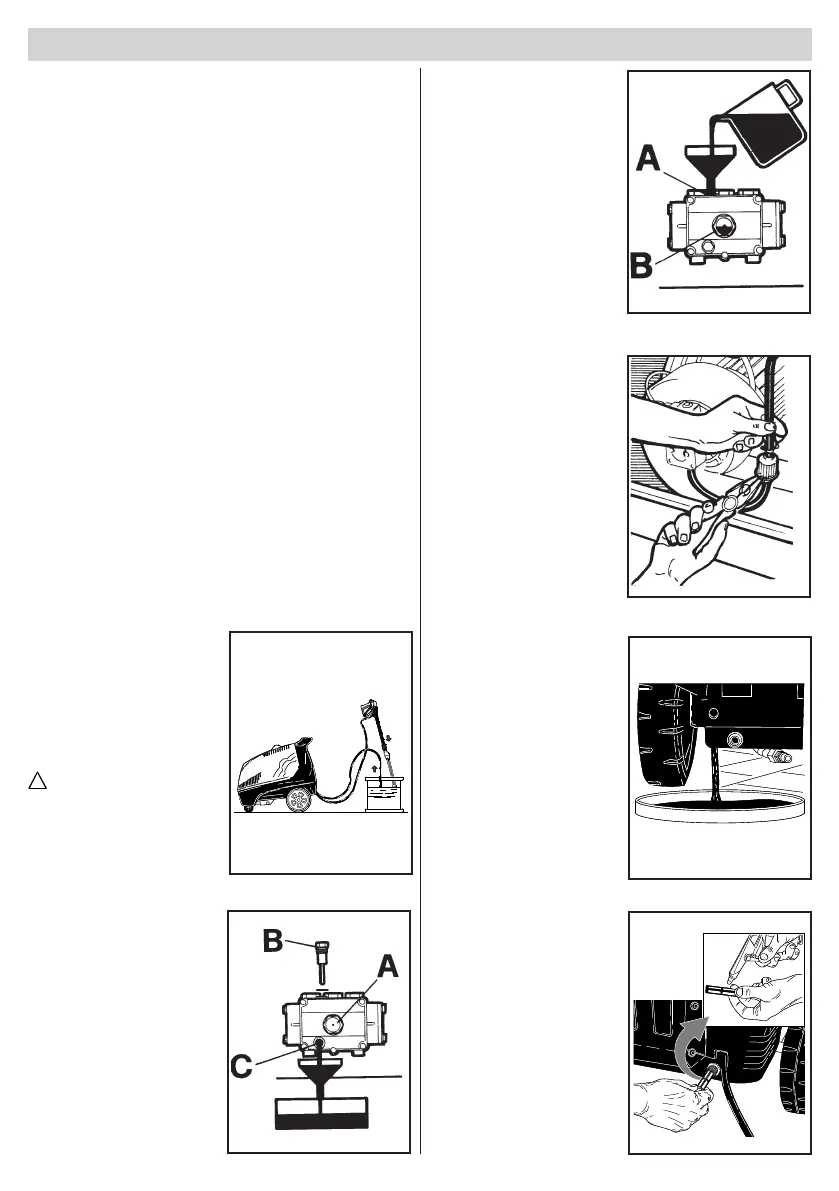

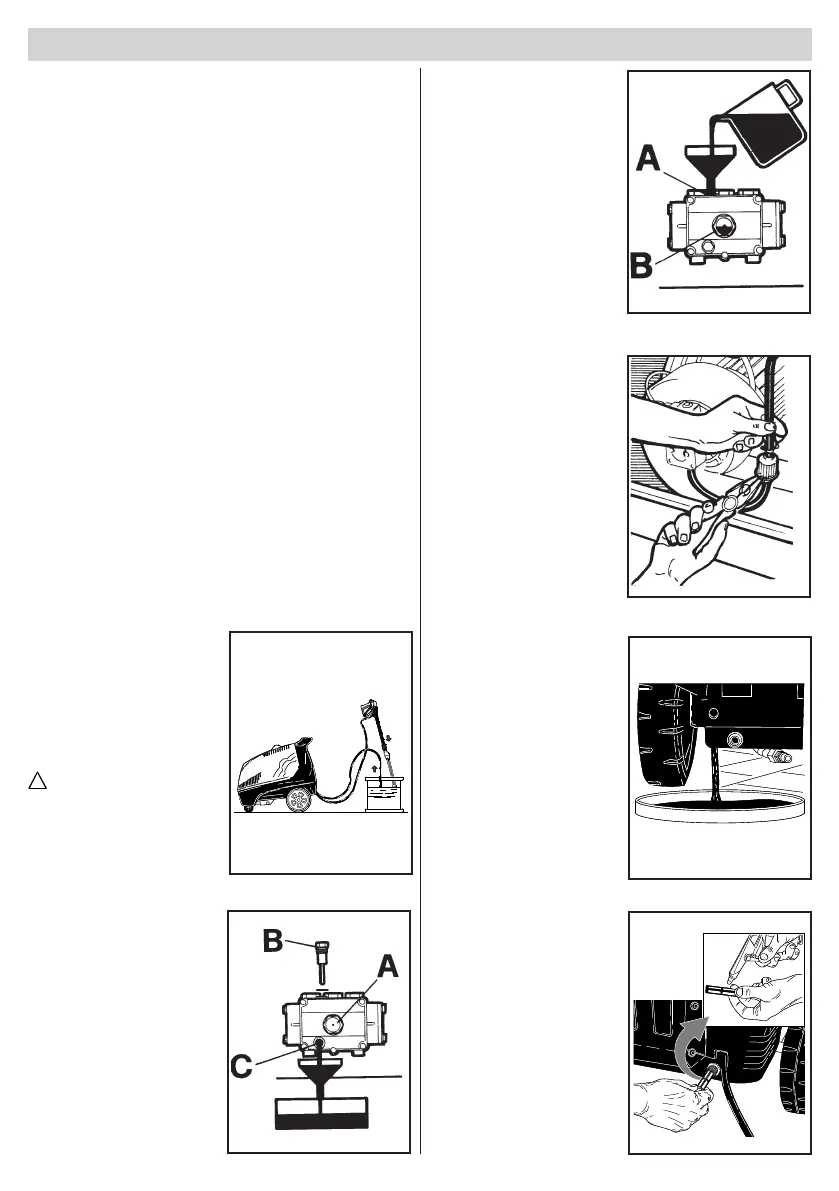

FIG.17

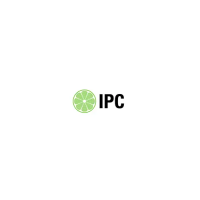

FIG.16

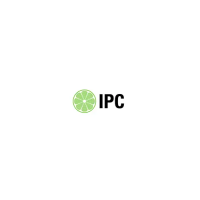

FIG.14

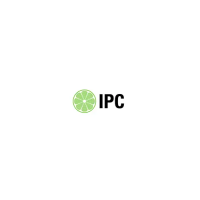

FIG.15

FIG.18

Proceed as follows:

1) Unscrew the drain cap

situatedunderthepump(g.

14C).

2) Unscrew the cap with the

dipstick(g.14).

3)Letalltheoildrainointo

a container and deliver it to an

authorized oil collection and

disposal centre.

4) Replace the drain screw

and pour fresh oil in through

the filling cap on top (fig.

15A) until it reaches the level

indicated on the sight glass

(g.15B).

For water cleaners without

oil drain bung, contact our

technical service centre for

replacement.

Use only SAE 15W 40 oil.

CLEANING THE FUEL FIL-

TER AND TANK.

Remove and replace the in-

linefuellter(g.16).

Change it from time to time.

Empty the fuel tank.

Openthedraincap(g.17)(if

available) and let any impuri-

ties drain out into a container.

Flush out the tank with clean

fuel and close the drain cap.

CLEANING THE WATER

FILTER

Clean the water intake lter

regularly and free it from any

impurities(g.18).

via the omnipolar switch or

by unplugging the plug from

the socket.

9) For high pressure cleaners

provided with water tank, the

detergent solution prepared

as described in the point 3,

must be poured directly into

the tank.

Warning

Anti-freeze may cause envi-

ronmental pollution. Always

follow the instructions given

on the pack. (Dispose of

carefully.)

CHECKING PUMP OIL LE-

VEL AND OIL CHANGE

From time to time check the

oil level in the high pressure

pump by means of the sight

glass(g.14A)orthedipstick

(g.14B).

If the oil has a milky appearan-

ce, call the technical service

centre immediately.

Change the oil after the rst

50 hours' work and subse-

quently every 500 hours or

once a year.

socket and close the water supply tap (see chapters on connec-

ting to the electricity and water mains) before carrying out any

maintenance jobs. Once maintenance has been completed,

ensure that the closing panels have been correctly reassembled

and anchored with the screws provided before reconnecting the

cleaner to the mains.

Failure to do so may cause a risk of electric shock.

PRECAUTIONS AGAINST FROST

The cleaner must not be exposed to frost.

If the cleaner is left in premises where it is exposed to frost,

when work is over or for storage, antifreeze must be used to

prevent serious damage to the hydraulic circuit.

OPERATIONS FOR USING ANTIFREEZE (g. 13).

1)Turnothewatersupply(tap),disconnectthehoseandrun

the cleaner until it is completely empty.

2) Stop the water cleaner with the ON/OFF switch in the “O”

position.

3) Prepare a container with the solution of antifreeze.

4) Immerse the tube in the container with the anti-freeze solu-

tion.

5) Start the water cleaner with the ON/OFF switch in the “I”

position.

6) Start the cleaner and let it run until antifreeze comes out

through the lance.

7) Suck up antifreeze with the detergent intake system too.

8) Disconnect the water cleaner from the mains electricity supply

FIG.13

Loading...

Loading...