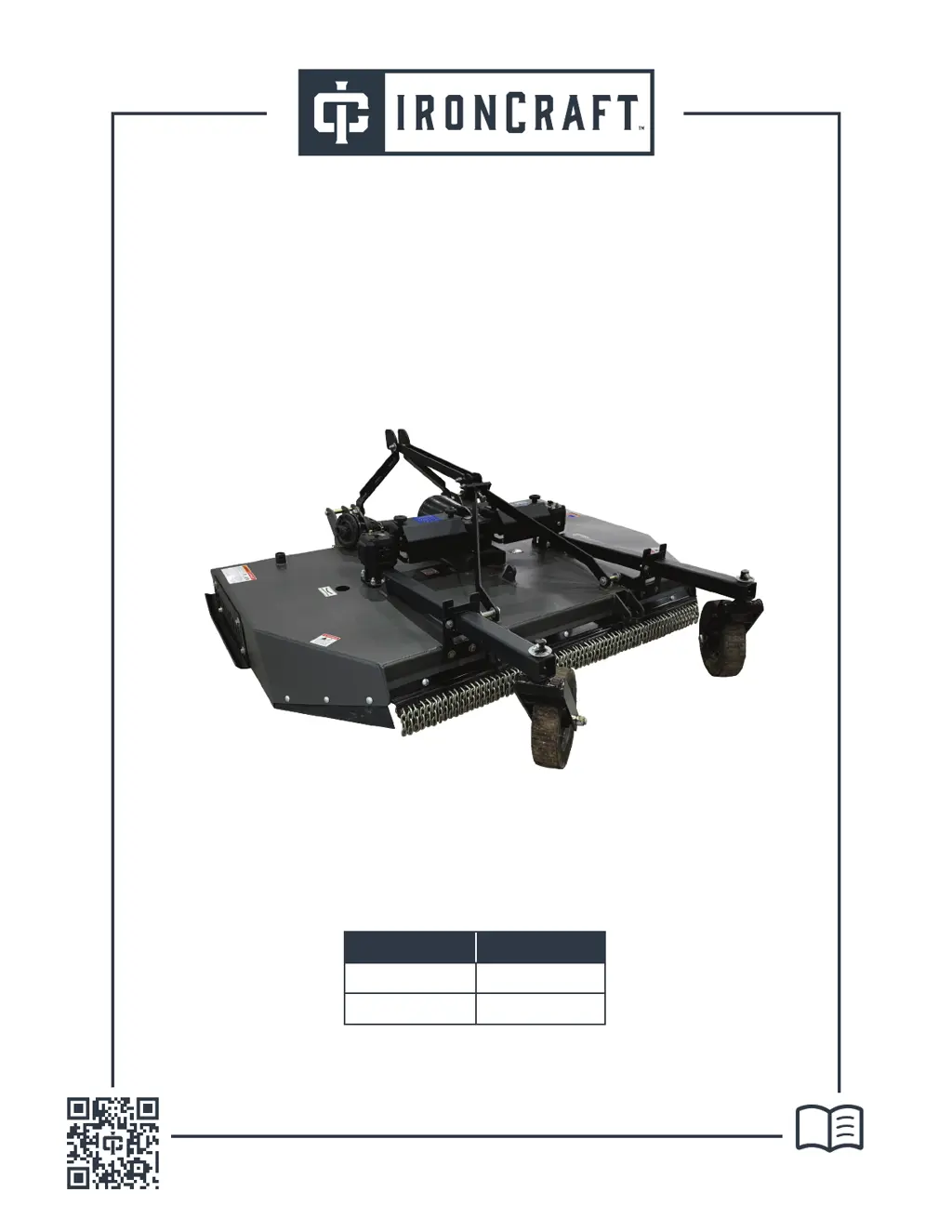

How to fix uneven cut with IronCraft 2400 Farm Equipment?

- JjonessamanthaAug 7, 2025

An uneven cut with your IronCraft Farm Equipment can occur for several reasons. Check the following: * Reduce ground speed if it's excessive. * Replace blades if they are worn, dull, or bent. * If the mower isn't level, adjust it. * Adjust the rotary cutter height if it's improper. * Correct low tractor tire pressure and adjust your tractor wheel spacing. * Reduce ground speed when turning. * Repair or replace a damaged cutter pan.