13

IVC US Commercial Installation Guide –

Laminate PXP & DXP

Installation

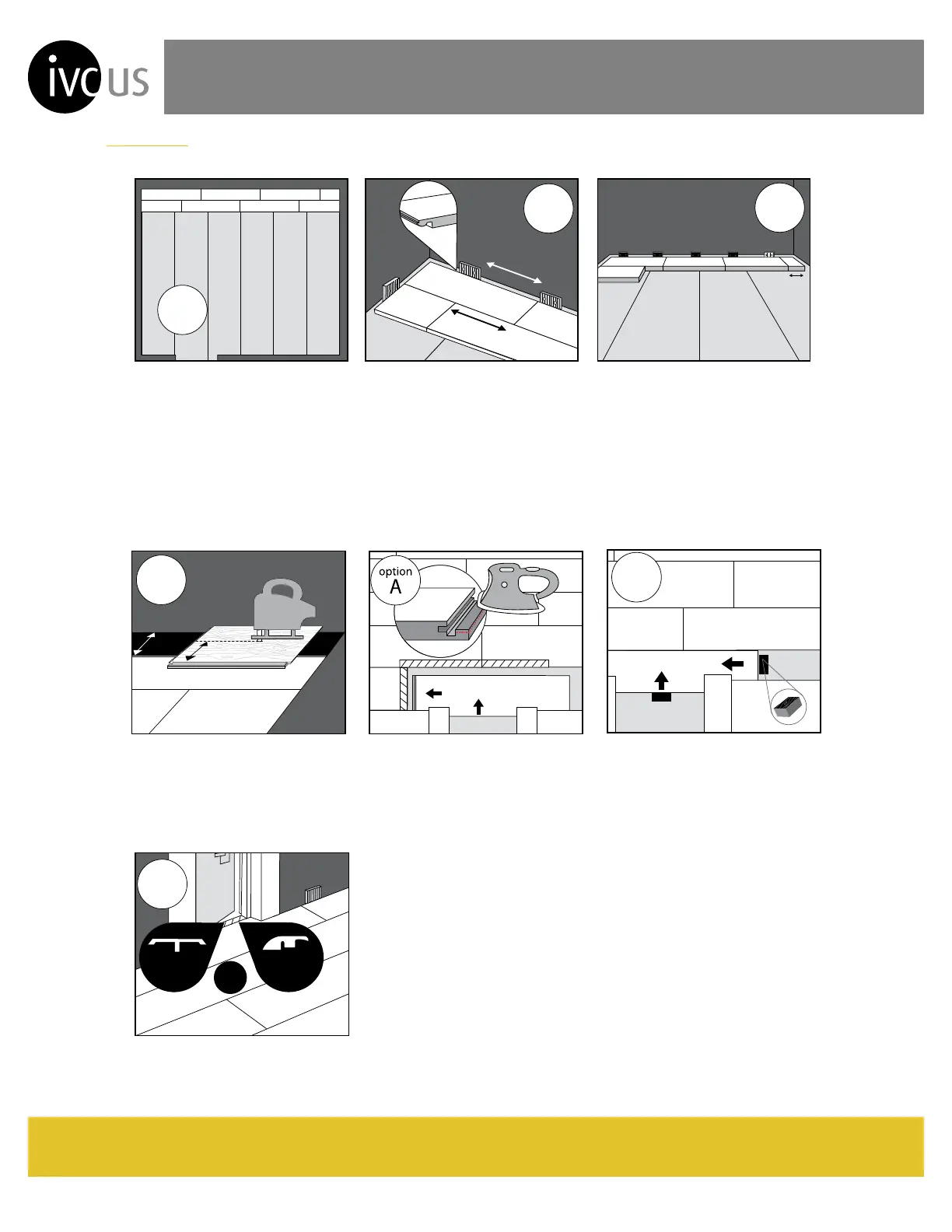

Installation Option A: Starting in the corner of a room

x mm

x inch

x inch = 3/8 inch

x mm = 8 mm

option

A

1 2 3 4a

4b 5

7b 8 9 10

11

14b

17b 18 19 20

27b 28 29 30

37b 38 39 40

47b

48

49 50

15 16 17a

24b 25 26 27a

34b 35 36 37a

44b 45 46 47a

12 13 14a

21 22 23 24a

31 32 33 34a

41 42 43 44a

6 7a

option

A

44b 45b

42

37b 38

48

47b

Last row: cut the plank along the length,

leaving room for the expansion gap, which

is 3/8 inch (8 mm)

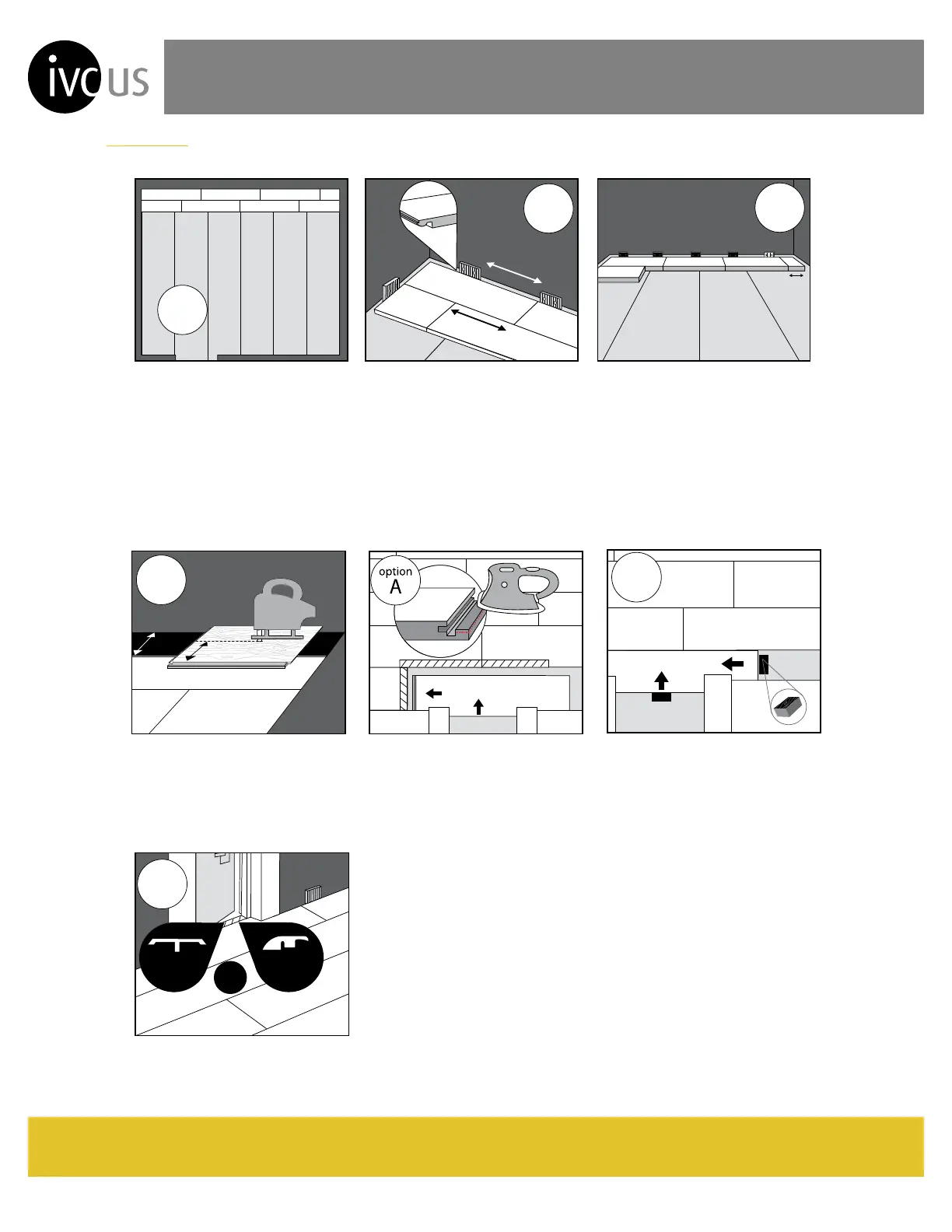

How to install along the doorway of the

last row (see plank 48)

How to install along the doorway of the

last row: Sand down the grooves of the

surrounding planks as indicated by the

dotted line (about 50% of the lip) with a

sander (short end plank 47b, along the

length for plank 44b and 45b).

Tap the piece being installed under the

doorway (plank 48) in to place with a

tapping block or a scrap piece. Tap along

the width and length as indicated with the

arrows.

*Only use tapping block under doorways.

Use end cap or connection SlimTrim to

finish off. It is recommended to

provide an expansion joint between

different rooms (i.e. under doorways)

End Cap

SlimTrim

(T-molding)

x mm

x inch

x inch = 3/8 inch

x mm = 8 mm

option

A

1 2 3 4a

4b 5

7b 8 9 10

11

14b

17b 18 19 20

27b 28 29 30

37b 38 39 40

47b

48

49 50

15 16 17a

24b 25 26 27a

34b 35 36 37a

44b 45 46 47a

12 13 14a

21 22 23 24a

31 32 33 34a

41 42 43 44a

6 7a

option

A

44b 45b

42

37b 38

48

47b

or

option

A

1

Last row: cut the plank along the length,

leaving room for the expansion gap, which

is 3/8 inch (8 mm)

How to install along the doorway of the

last row (see plank 48)

How to install along the doorway of the

last row: Sand down the grooves of the

surrounding planks as indicated by the

dotted line (about 50% of the lip) with a

sander (short end plank 47b, along the

length for plank 44b and 45b).

Tap the piece being installed under the

doorway (plank 48) in to place with a

tapping block or a scrap piece. Tap along

the width and length as indicated with the

arrows.

*Only use tapping block under doorways.

Use end cap or connection SlimTrim to

finish off. It is recommended to

provide an expansion joint between

different rooms (i.e. under doorways)

End Cap

SlimTrim

(T-molding)

x mm

x inch

x inch = 3/8 inch

x mm = 8 mm

option

A

1 2 3 4a

4b 5

7b 8 9 10

11

14b

17b 18 19 20

27b 28 29 30

37b 38 39 40

47b

48

49 50

15 16 17a

24b 25 26 27a

34b 35 36 37a

44b 45 46 47a

12 13 14a

21 22 23 24a

31 32 33 34a

41 42 43 44a

6 7a

option

A

44b 45b

42

37b 38

48

47b

45b

4241

48

option

A

1

Last row: cut the plank along the length,

leaving room for the expansion gap, which

is 3/8 inch (8 mm)

How to install along the doorway of the

last row (see plank 48)

How to install along the doorway of the

last row: Sand down the grooves of the

surrounding planks as indicated by the

dotted line (about 50% of the lip) with a

sander (short end plank 47b, along the

length for plank 44b and 45b).

Tap the piece being installed under the

doorway (plank 48) in to place with a

tapping block or a scrap piece. Tap along

the width and length as indicated with the

arrows.

*Only use tapping block under doorways.

Use end cap or connection SlimTrim to

finish off. It is recommended to

provide an expansion joint between

different rooms (i.e. under doorways)

End Cap

SlimTrim

(T-molding)

1

4b 5

38

6 7a

2 3 4a

31

option

A

max 20 inches / 50 cm

Tongue Side

option

A

1

min 10 inches / 25 cm

2

4b

1 2

3

4a

option

A

min

25 cm

10 inch

4b

Installation Option A: Starting in the

corner of a room

Expansion gaps along the perimeter and

xed objects: min 3/8 inch (8 mm)

You can go both directions but we

recommend to go from left to right.

Tongue facing the wall. Start installing

the rst row by clicking the end joints

together (follow your specic click system

guidelines). Spacers must be placed at

least every 20“ (50 cm).

Adjoining rows: joint separation must be

at least 10” (25 cm).

Cut last laminate plank at the end of the

row (4a): min 10 inches (25 cm).

Use the remaining cut piece (4b) or a

random cut piece so as not to show a

repeating pattern to start the adjoining

row.

To click the planks together: angle the

adjoining row along the length. Then

angle the tongue of plank you are

installing into the groove of the adjoining

row. Tongue must face the previously

installed row. Black plastic insert must sit

in place. Then rotate downwards as

indicated with the arrow.

Click the end joints together by pushing

the end joint downwards on the left edge

of plank you are installing until you hear a

click or snap. Do not tap.

Repeat step for the rest of the room.

PXP PXP

x mm

x inch

x inch = 3/8 inch

x mm = 8 mm

option

A

1 2 3 4a

4b 5

7b 8 9 10

11

14b

17b 18 19 20

27b 28 29 30

37b 38 39 40

47b

48

49 50

15 16 17a

24b 25 26 27a

34b 35 36 37a

44b 45 46 47a

12 13 14a

21 22 23 24a

31 32 33 34a

41 42 43 44a

6 7a

44b 45b

42

37b 38

48

47b

48

option

A

or

option

A

1

Last row: cut the plank along the length,

leaving room for the expansion gap, which

is 3/8 inch (8 mm)

How to install along the doorway of the

last row (see plank 48)

How to install along the doorway of the

last row: Sand down the grooves of the

surrounding planks as indicated by the

dotted line (about 50% of the lip) with a

sander (short end plank 47b, along the

length for plank 44b and 45b).

Tap the piece being installed under the

doorway (plank 48) in to place with a

tapping block or a scrap piece. Tap along

the width and length as indicated with the

arrows.

*Only use tapping block under doorways.

Use end cap or connection SlimTrim to

finish off. It is recommended to

provide an expansion joint between

different rooms (i.e. under doorways)

End Cap

SlimTrim

(T-molding)

This document is reviewed on an ongoing basis.

MKF_0029_2 10/28/15

Loading...

Loading...