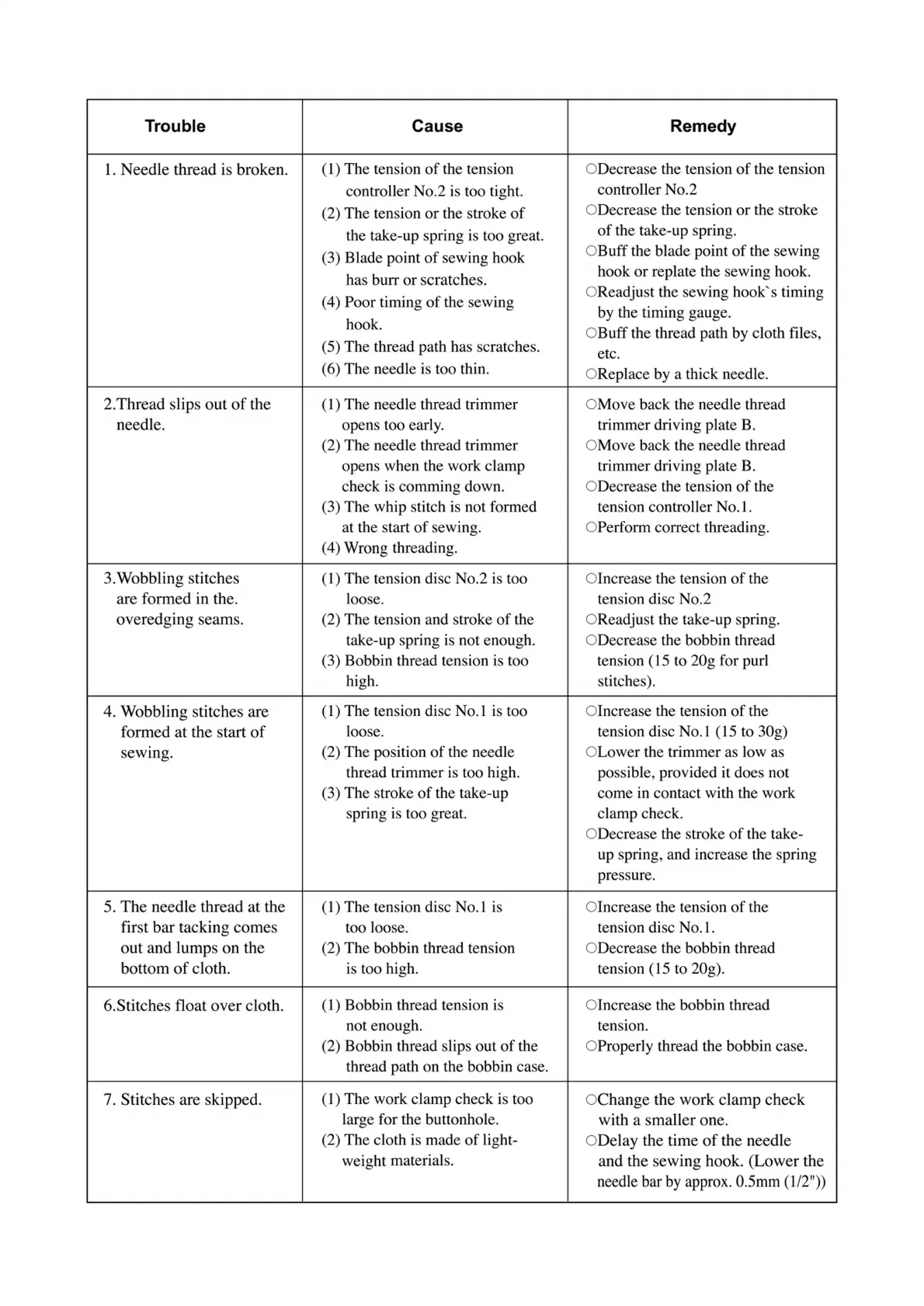

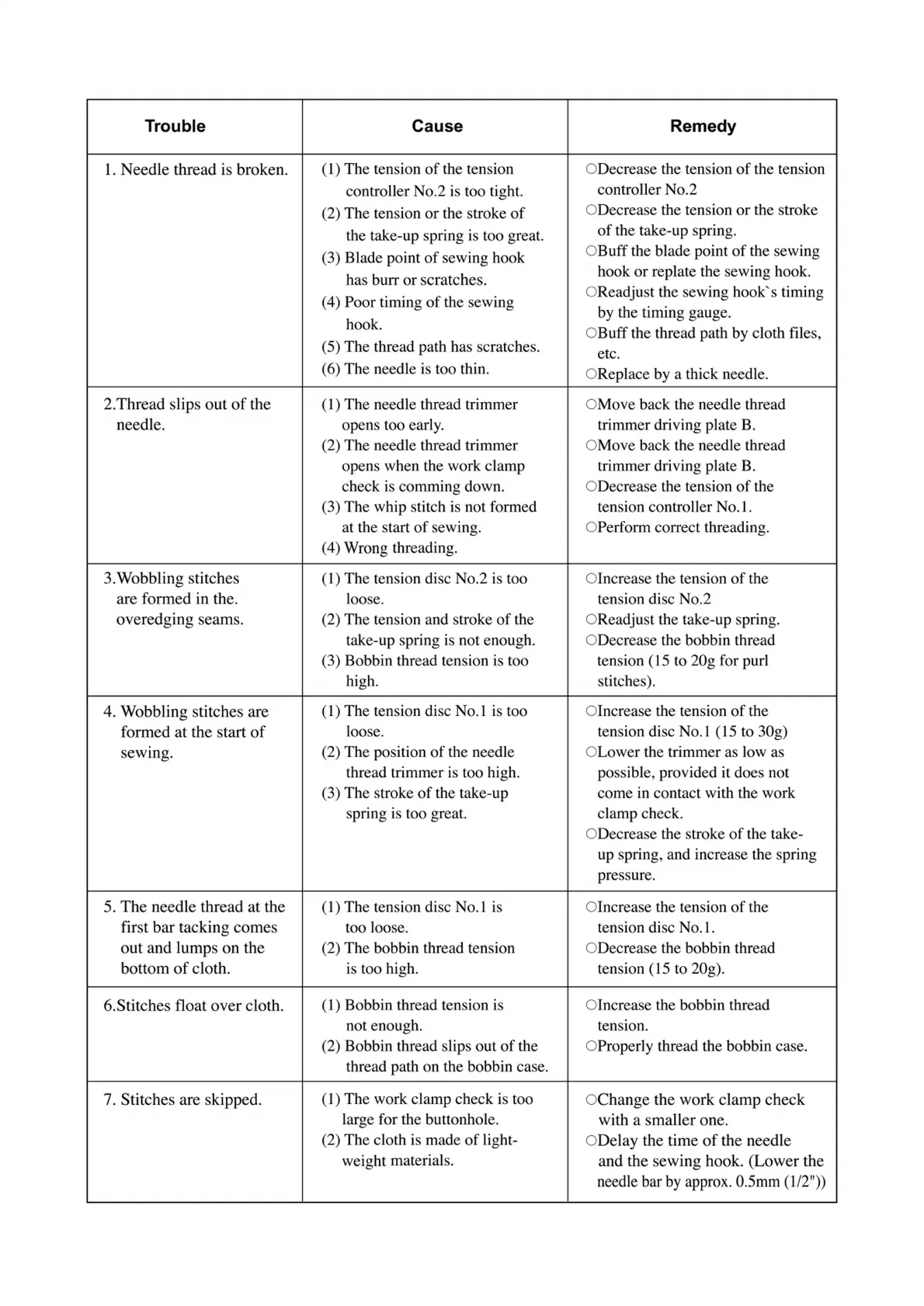

Trouble

Cause

Remedy

1.

Need

le thread is broken.

(1) The tension of the tension ODecrease the tension

of

the tension

controller No.2 is too tigh

t.

controller No.2

(2) The tension

or

the stroke

of

ODecrease the tension

or

the stroke

the take-up spring is too grea

t.

of

the take-up spring.

(3) Blade point

of

sewing hook

OBuff the blade point

of

the sewing

has burr or scratches.

hook

or

replate the sewing hook.

(4) Poor timing

ofthe

sewing

OReadjust the sewing hook' s timing

by the tirning gauge.

hook.

OBuff the thread path by cloth files

,

(5) The thread path has scratche

s.

etc.

(6) The needle is too thin.

OReplace by a thick needle.

2.Thread slips

out

of

the (J) The needle thread trimmer

OMove back the needle thread

needle. opens too early. trimmer driving plate B.

(2) The needle thread trimmer OMove back the needle thread

opens when the work

cI

amp trimmer driving plate B.

check is comming down. ODecrease the tension

of

the

(3) The whip stitch is not formed tension controller

No.l

.

at the start

of

sewing. OPerform correct threading.

(4) Wrong threading.

3.Wobbling stitch

es

(l)

The tension disc No.2 is too OIncrease the tension

of

the

are

formed in the. loose. tension disc No.2

overedging seams. (2) The tension and stroke

of

the OReadjust the take-up spring.

take-up spring is not enough.

ODecrease the bobbin thread

(3) Bobbin thread tension is too tension

(1

5 to 20g for purl

high. stitches).

4. Wobbling stitches are

(1) The tension disc No.l is too OIncrease the tension

of

the

formed

at

the

start

of

loose.

tension disc No. l (15 to 30g)

sewmg.

(2) The position

of

the needle OLower the trimmer as low as

thread trimmer is too high.

possible

, provided

it

does not

(3) The stroke

of

the take-up

come in contact with the work

spnn

g IS too grea

t.

cI

amp check.

ODecrease

th

e stroke

of

the take-

up spring

, and increase the spring

pressure.

5.

The

needle thread

at

the (1) The tension disc No.l is OIncrease the tension

of

th

e

first

bar

tacking

comes

too loose.

tension disc

No.l.

out

and

lumps

on

the

(2) The bobbin thread tension

ODecrease

th

e bobbin thread

bottom

of

cloth. is too high. tension

CI

5 to 20g).

6.Stitches float

over

cloth.

(1) Bobbin thread tension is Olncrease the bobbin thread

not enough. tens

lO

n.

(2) Bobbin thread slips out

of

the OProperly thread the bobbin case.

thread path on the bobbin

ca

se.

7. Stitches are skipped.

(1) The work clamp check is too

O

Change

the

work

clamp

check

large for the buttonhole.

with a smaller one.

(2) The cloth is made

of

light-

ODelay the

time

of

the

needle

weight materials.

and

the

s

ewing

hook.

(Lower

the

needle bar

by

approx. O.5mm (1/2"))

Loading...

Loading...