9

Midsize

Classic

MAINTENANCE

Oil (daily)

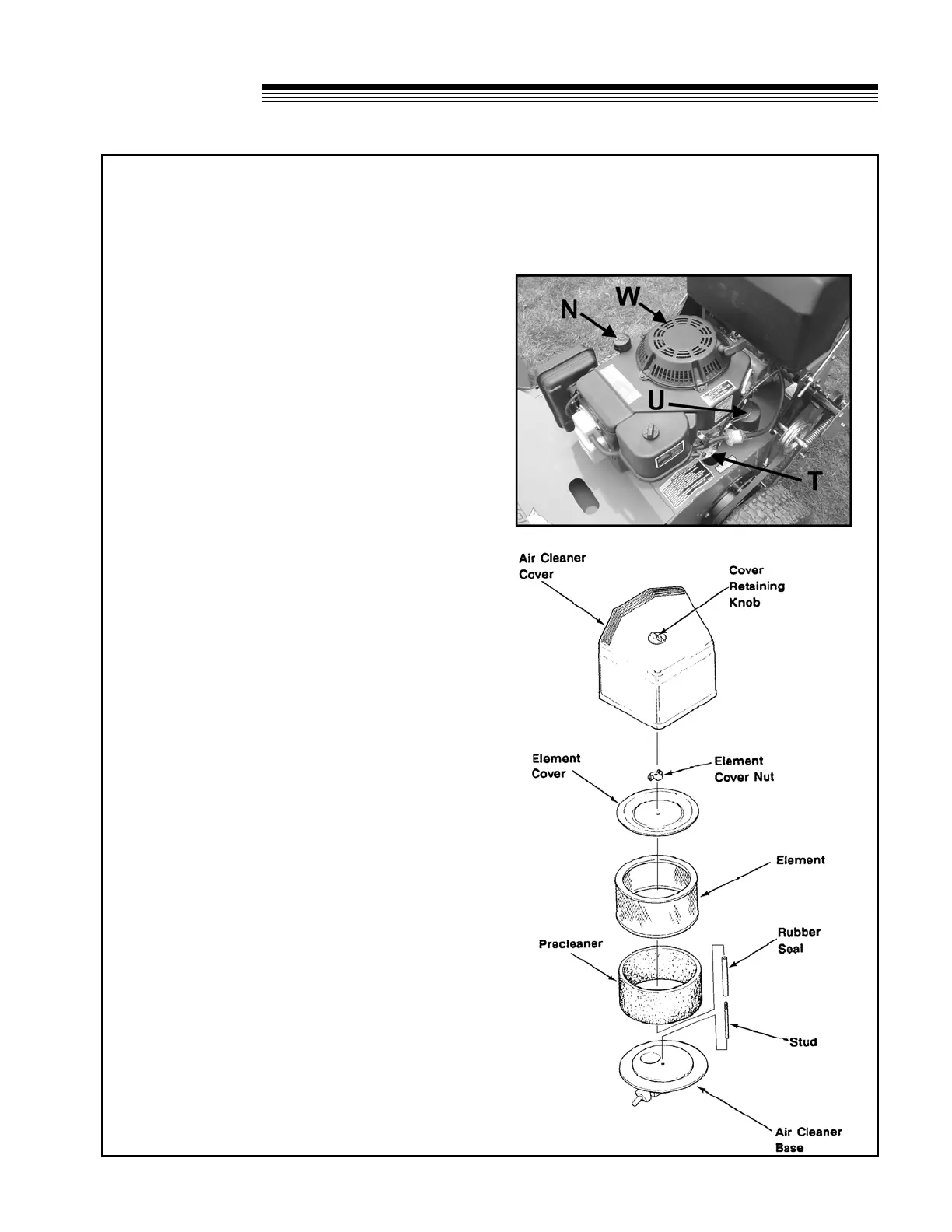

Remove the dipstick N and check that the oil level

reaches the full mark. If necessary, top off with fresh oil.

To obtain the correct oil level, the machine must be

level. See engine manufacturer’s manual for proper oil

viscosity and grade. DO NOT OVER FILL!

AFTER THE FIRST 5 WORKING HOURS

While the engine is warm, remove the drain plug T and

drain the crankcase. Replace oil filter U. Clean and

replace the plug. Fill the crankcase through the filler

hole with fresh oil to the full mark. See engine

manufacturers manuals for oil and filter change

intervals.

Cooling Fins and Air Intake screen (daily)

Ensure that the cooling fins and air intake screen W

are cleaned daily. Continued operation with a

clogged cooling system will cause severe

overheating and result in engine damage.

Air Cleaner

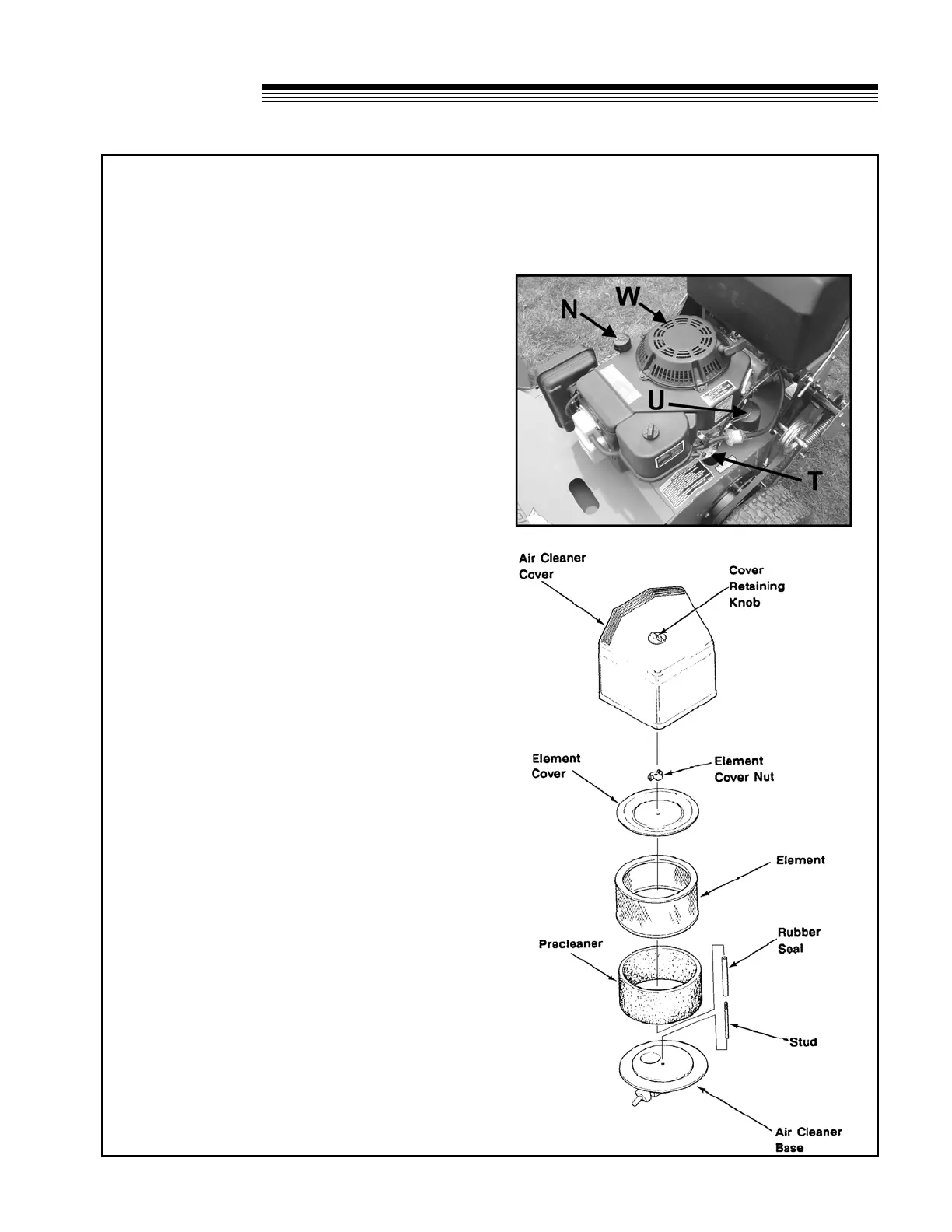

Dual element air cleaners have a paper air cleaner

element with an oiled, foam precleaner element on

the dirty side of the paper element. Both should be

inspected regularly and maintained.

Clean and re-oil precleaner element every 25 hours

(more often under dusty conditions).

1. Disassemble air cleaner cover.

2. Remove precleaner by sliding it off the paper

cartridge.

3. Wash precleaner in kerosene or liquid detergent

and water.

4. Wrap precleaner in cloth and squeeze to remove

cleaner.

5. Saturate precleaner in engine oil. Squeeze to

remove excess oil.

6. Re-install precleaner over paper cartridge.

Reassemble air cleaner components and screw

assembly down tight.

Every 100 hours (more often under very dusty or

dirty conditions), check the paper cartridge.

– Clean by tapping gently.

– Do not wash the cartridge or use compressed air

– Replace when cartridge is dirty, bent or

damaged.

ENGINE - KOHLER

The maintenance schedule detailed is for average operating conditions. Under extreme conditions (dusty,

dirty or more than 8 hrs continuous use) maintain more frequently.

Loading...

Loading...