11

Midsize

Classic

MAINTENANCE

BLADE SHARPENING

Blades may be sharpened by filing or grinding, but with either method the balance of the blades must be

maintained at 5/8 oz/in or less. Failure to maintain balance causes excess vibration, wear and shortened life

of not only the blades, but most all components of the machine. To balance a blade after sharpening: attach

1/8 oz of weight 5" from center on the light end. This should make the light end the heavy end. If it does not:

file or grind the heavy end until the addition of weight makes the light end the heavy end.

Cutterdeck Pulley Assembly

NOTE:

• Do not overheat or weaken the blades.

• Do not straighten bent blades. Replace with new

Bob-Cat blades.

If lift portion of blade is worn thin replace with a

new Bob-Cat blade.

• ALWAYS replace with Bob-Cat blades—do not

use another manufacturer’s blades as this could

be dangerous.

• Replace cracked or bent blades.

BLADE REMOVAL

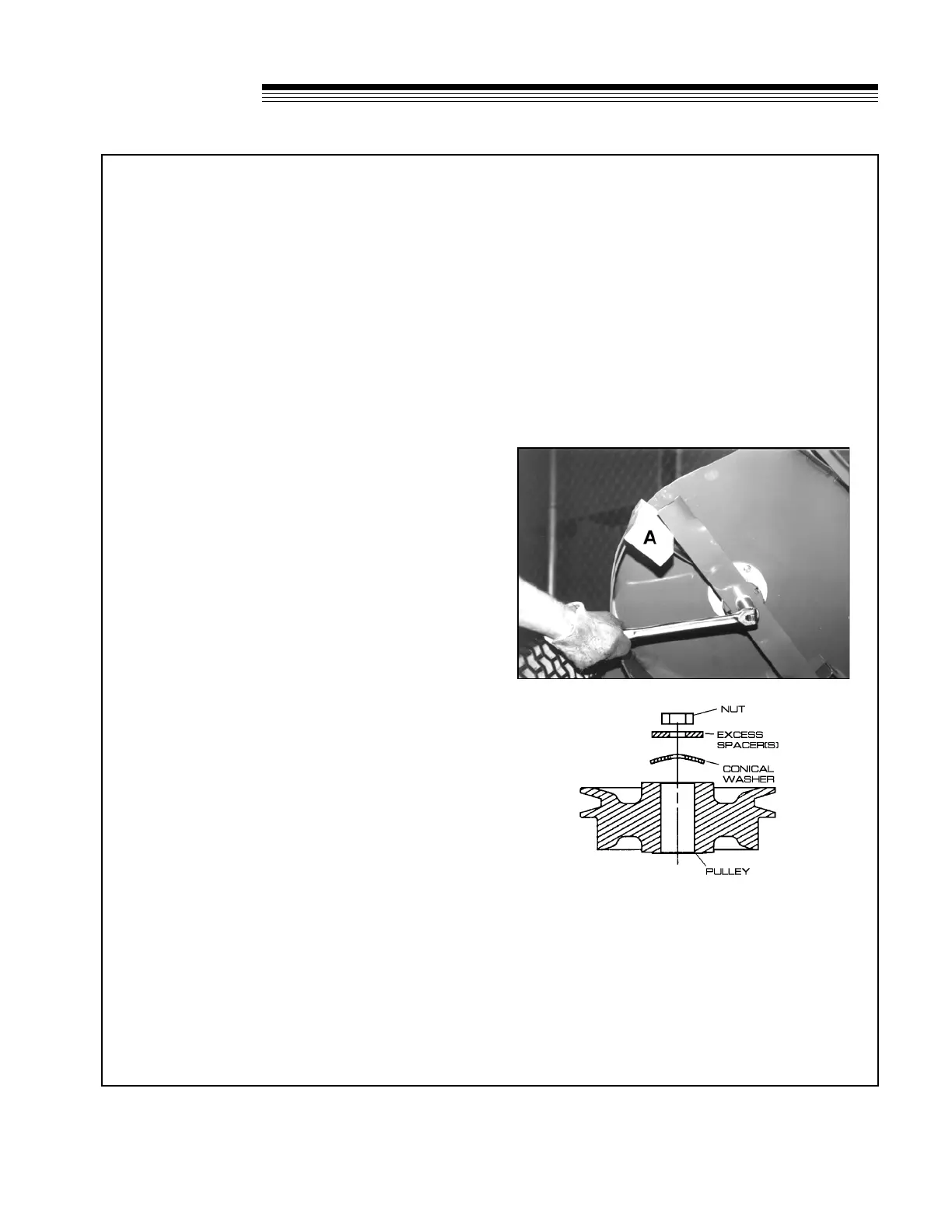

1. Use a box wrench or socket with a long breaker

bar to remove spindle bolt under cutterdeck.

2. Slip tube over breaker bar or wrench if

necessary to gain leverage.

3. Keep hands clear as blades may rotate when

bolt releases.

4. When changing blades, wear thickly padded

gloves.

5. Block blades from turning by using a piece of

wood.

6. Follow these instructions to prevent injury when

bolt releases.

NOTE: To prevent blade from turning, place block

of wood at location A, with grain perpendicular to

blade.

BLADE RE-INSTALLATION

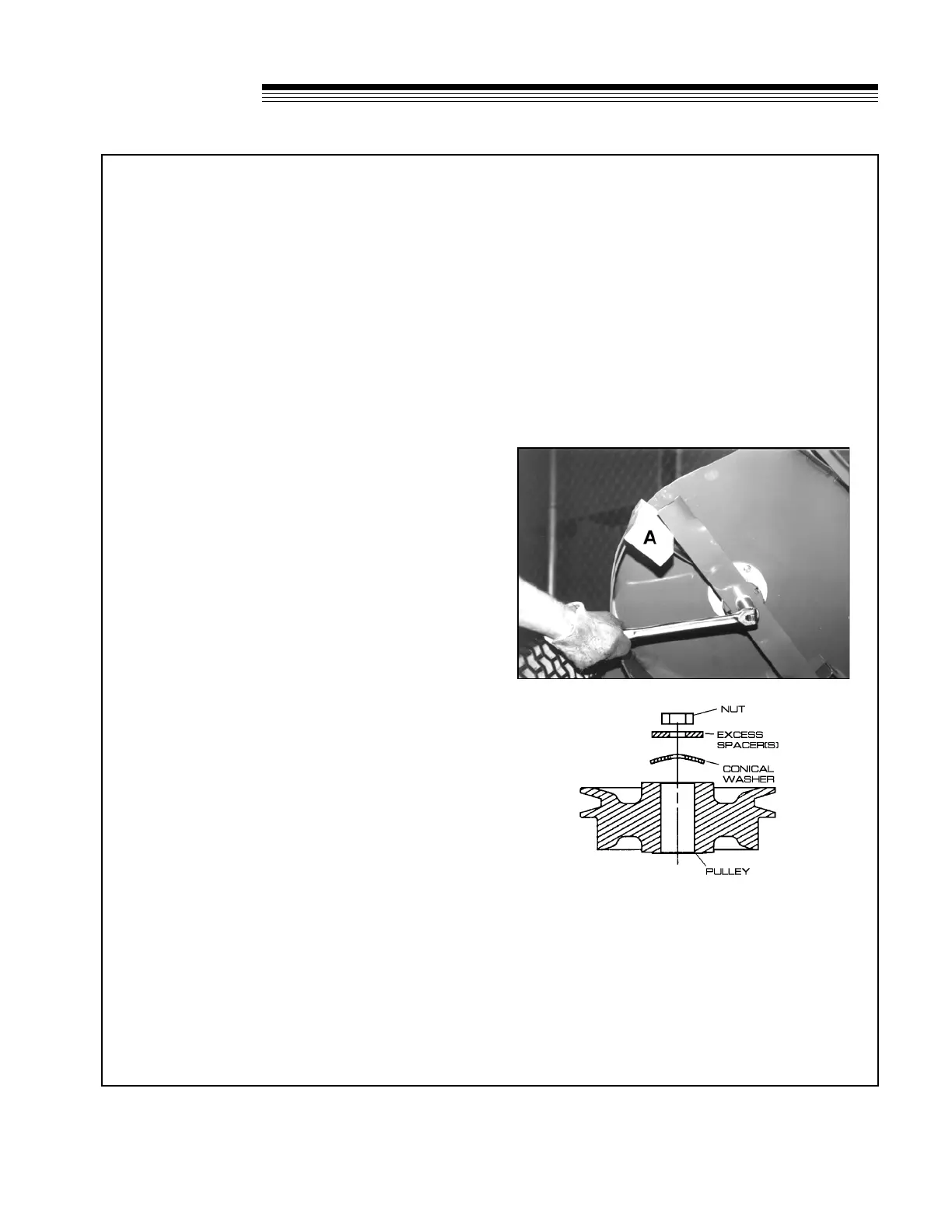

1. Place the desired number of spacers (no more

than 2) on the spindle bolt below the cutterdeck

between the blade and spindle shaft.

2. Insert the cutter spindle bolt (from bottom)

complete with washer, blade and spacers.

3. Place remaining spacer(s) on the spindle bolt

above the cutterdeck between the conical

washer and nut (as shown). Replace nut and

tighten to 70 ft-lbs.

Loading...

Loading...