Do you have a question about the Jarvis JC III and is the answer not in the manual?

Key duties for employers to ensure safe tool operation and prevent injuries.

Essential safety guidelines for operating, maintaining, and cleaning the dehyder.

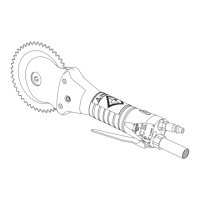

Visual representation and list of all parts for the JC III dehyder.

Detailed technical data including motor power, operating pressure, and dimensions.

Details on compressed air supply pressure and CFM needed for the dehyder.

Instructions for installing and maintaining the air filter/regulator/lubricator.

Daily checks including trigger function, air supply, and lubrication.

Procedure for greasing specific fittings three times per shift.

Flushing air motor, cleaning and sharpening blades.

Step-by-step guide for taking apart the gear and shaft assembly.

Instructions for reassembling the gear and shaft components.

Procedure for removing components of the air motor.

Steps for reassembling the air motor with packed bearings.

Loading...

Loading...