www.jawamoped.com

Crankshaft aligning

Check the aligning and the permissible untrue run using

a special jig with centres and two dial indicators. The

crankshaft must be supported in the centres so that it can

rotate. The maximum permissible relative run-out of the

functional points is 0.016mm. The functional points in

this instance are the shoulders for the bearings. The

design of the crankshaft and the manufacturing process

guarantee this value. Check the run-out or untrue run

before installing the crankshaft in the engine.

Misalignment of the crankshaft is usually caused by a

crash, rough handling during transport, dropping the

crankshaft on the ground or by an unskilled repair. You

will obtain the correct axial (lateral) clearance of the

crankshaft in the crankcase if you maintain the

dimension 38-0.2mm (distance of the shoulders for the

bearings) when pressing the crankshaft together. The

minimum distance of the flywheels in place on the

crankpin must be 12.2mm.

Crankshaft aligning and straightening procedure

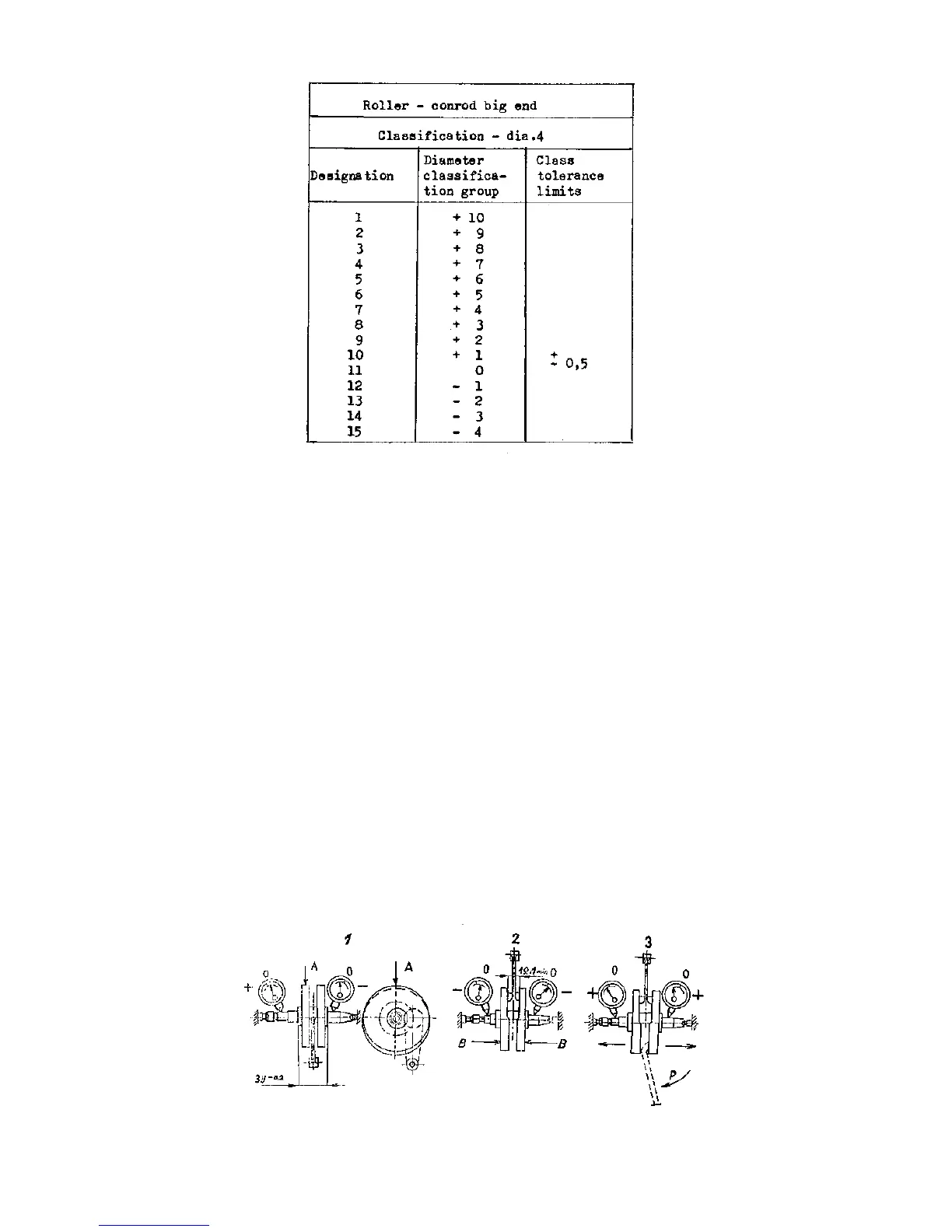

Check the alignment of crankpins as illustrated in Fig

23. If the crankshaft halves are mutually set off, remove

the crankshaft from the centres,

and using a suitable copper or aluminium pad and a

hammer of soft material work on it till the crankpins are

aligned as perfectly as possible The two crankshaft

halves are not set off if both dial indicators give the

same readings when rotating the crankshaft. If after this

procedure the mutual run-out of the functional parts is

greater than 0.016mm, straighten the crankshaft (its

axis) by bending both its halves against each other in the

required direction.

This procedure is depicted in Fig. 23. Depending on the

deflection of the crankshaft axis (ascertained by dial

indicators), bend the flywheels toward each other ( - -

readings) or away from each other (+ + readings). If

necessary, repeat the bending on more planes than the

one given in the illustration.

Decisive for the final straightening is the maximum

permissible untrue run of the functional part (surfaces)

of 0.016mm. If you fail to obtain this value by the

described procedure, it means that the crank mechanism

is defective and has to be replaced with a new one. As

this work requires great skill, it should be done by a

highly qualified fitter.

Fig. 23

ZVL model 210 Workshop Manual Page 18 jkw

Loading...

Loading...