www.jbstools.com

5

MAINTENANCE

Clean any dirt of the Lift Table, avoid having any foreign material potentially interfering with the

brake and wheels. Periodic lubrication with a light grease/oil on components will ensure smooth

operation. The general disassembling of the Lift Table should be performed by a skilled service

technician; please contact WIS Solutions P/L.

INSPECTIONS ARE VERY IMPORTANT IN DETERMINING WHETHER A DEFICIENCY HAS

OCCURRED CONSTITUTING A SAFETY RISK.

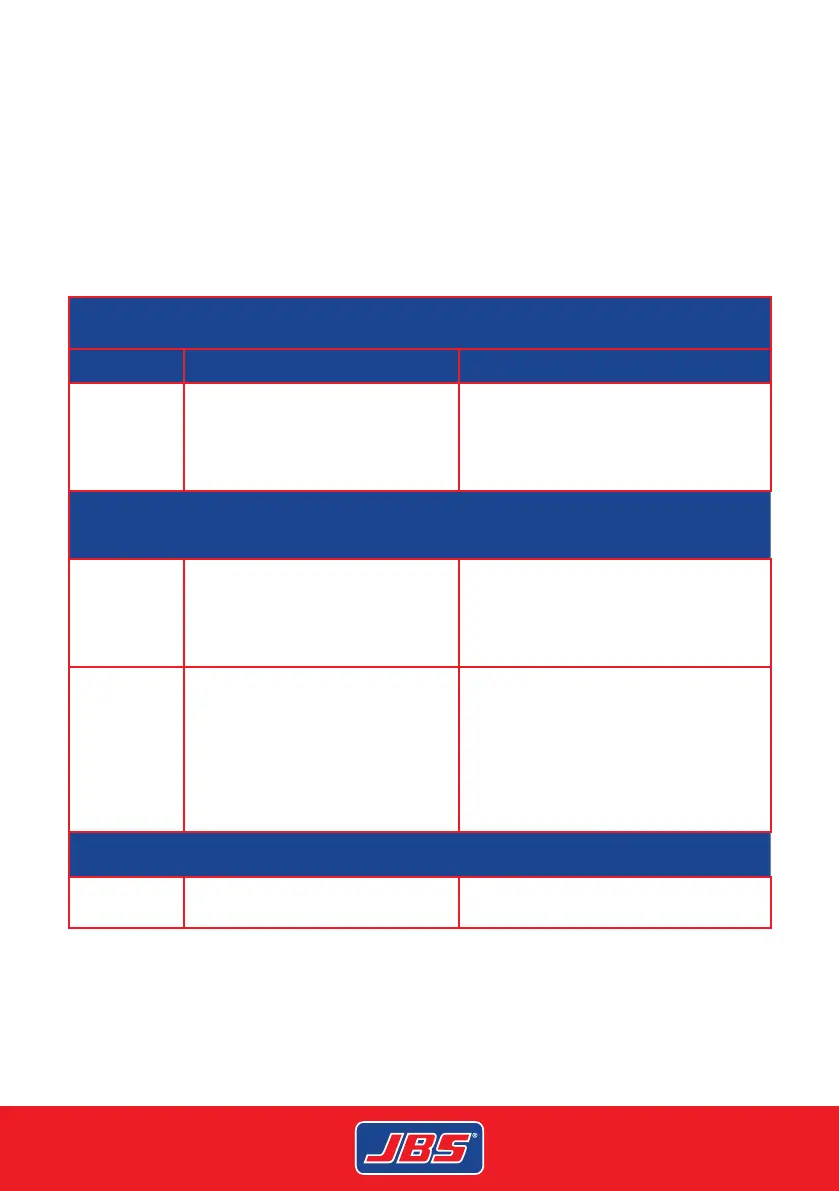

TYPE ACTION SUGGESTION

Visual and

Audio Check

■

Bending or cracking of platform

■

Oil leaking from cylinder

■

Vertical creep of platform

■

Wheel movement

■

Suspend unit from service and replace table

■

Suspend from service and replace cylinder

■

Tighten bolt

■

Dislodge any material caught in the wheel

Operation

Visual and

Audio

■

As per frequent inspection

■

Add oil

■

Change oil

■

Adjust the nut

■

Banish air

Components

Grease/Oil components:

■

Fitting Cylinder

■

Roller Friction Surface

■

Link Pin

■

Pedal Fitting Point

■

Grease Nipple

■

Oil

■

Grease

■

Oil

■

Oil

■

Grease

Components

■

Hydraulic Cylinder

■

Change Hydraulic Oil

Periodic: performed by qualified person

(to be completed Monthly)

Frequent : performed by operator prior to each use

Annual: performed by qualified person

Loading...

Loading...