01 - Machine

03 - Safety

27 - Maintenance Positions

01 - 16 9813/5150-2 01 - 16

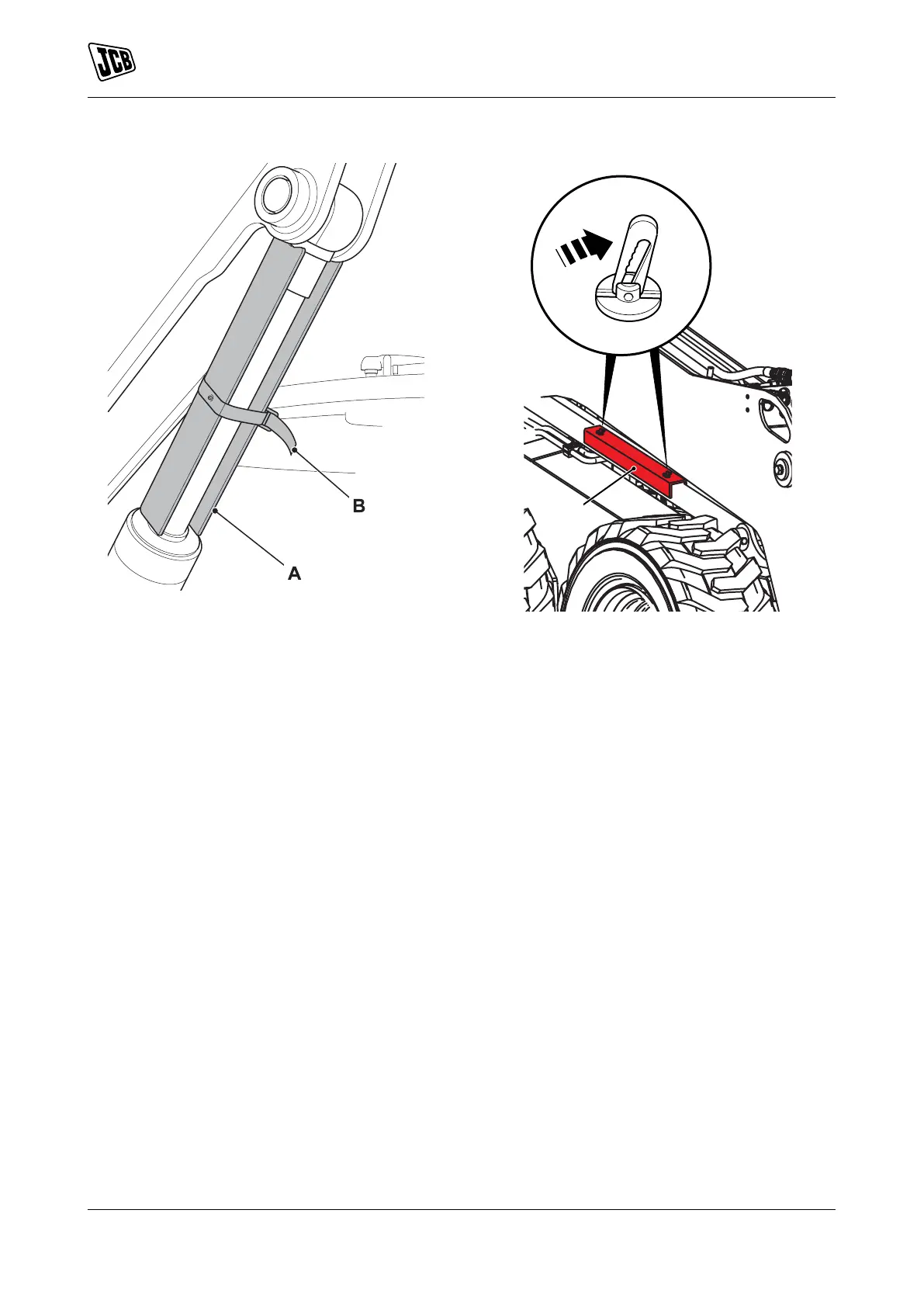

Figure 5.

A Strut

B Strap

7. To prevent any chance of the lift arm creeping

down and trapping your fingers, the lift arm

should be lowered onto the strut. Lower the arm

carefully, to prevent possible damage to the strut.

Stop as soon as the weight of the lift arm is on

the strut.

8. Disconnect the battery to prevent accidental

operation of the engine. Refer to (PIL 33-03).

9. If necessary, put blocks against the two sides of

the wheels before you get below the machine.

Removing the Lift Arm Maintenance Strut

1. Raise the lift arm to take the weight off of the strut.

2. Stop the engine and remove the ignition key. If

the keyless ignition option is installed stop the

engine and wait

Duration: 15s

3. Remove the strut.

4. Secure the strut in its stowage position.

5. Lower the lift arm to the ground.

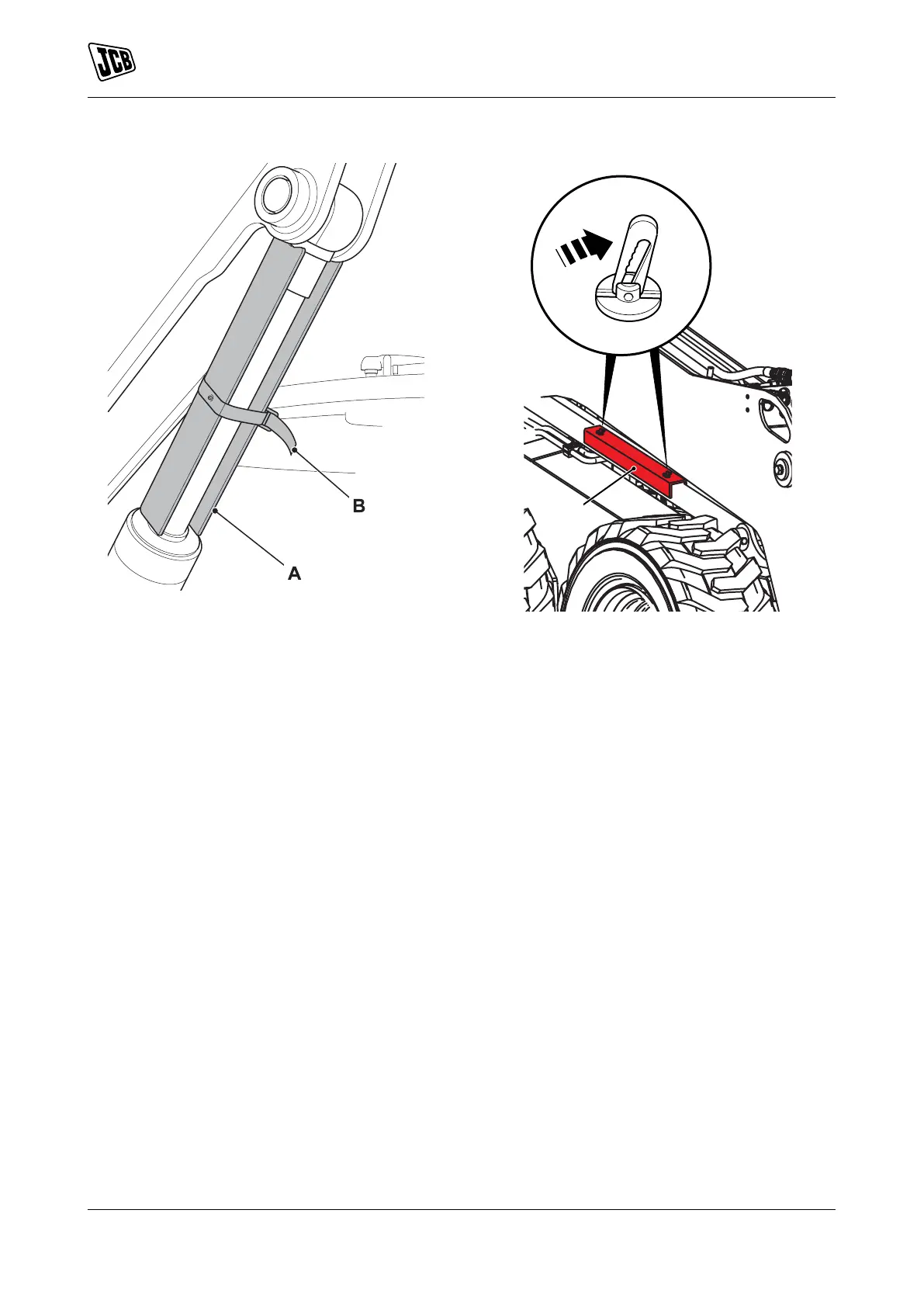

Figure 6.

C Stowage position

(For: 225T [T3 GE0], 225T [T4F GE0], 260

[T3 GE0], 260 [T4F GE0], 260T [T3 GE0],

260T [T4F GE0], 280 [T3 GE0], 280 [T4F

GE0], 300 [T3 GE0], 300 [T4F GE0], 300T

[T3 GE0], 300T [T4F GE0], 320T [T3 GE0],

320T [T4F GE0], 325T [T4F GE0], 330 [T3

GE0], 330 [T4F GE0])

Make the machine safe before you start a

maintenance procedure.

You can complete most of the maintenance

procedures with the lift arm lowered. Unless a

maintenance procedure instructs you differently, you

must lower the lift arm.

If you raise the lift arm to get access for maintenance,

you must install the maintenance strut on the lift arm.

If the cab is to be lifted to get access for

maintenance, you must raise the lift arm and install

the maintenance strut on the lift arm.

Release the hydraulic pressure.

Loading...

Loading...