- 3 -

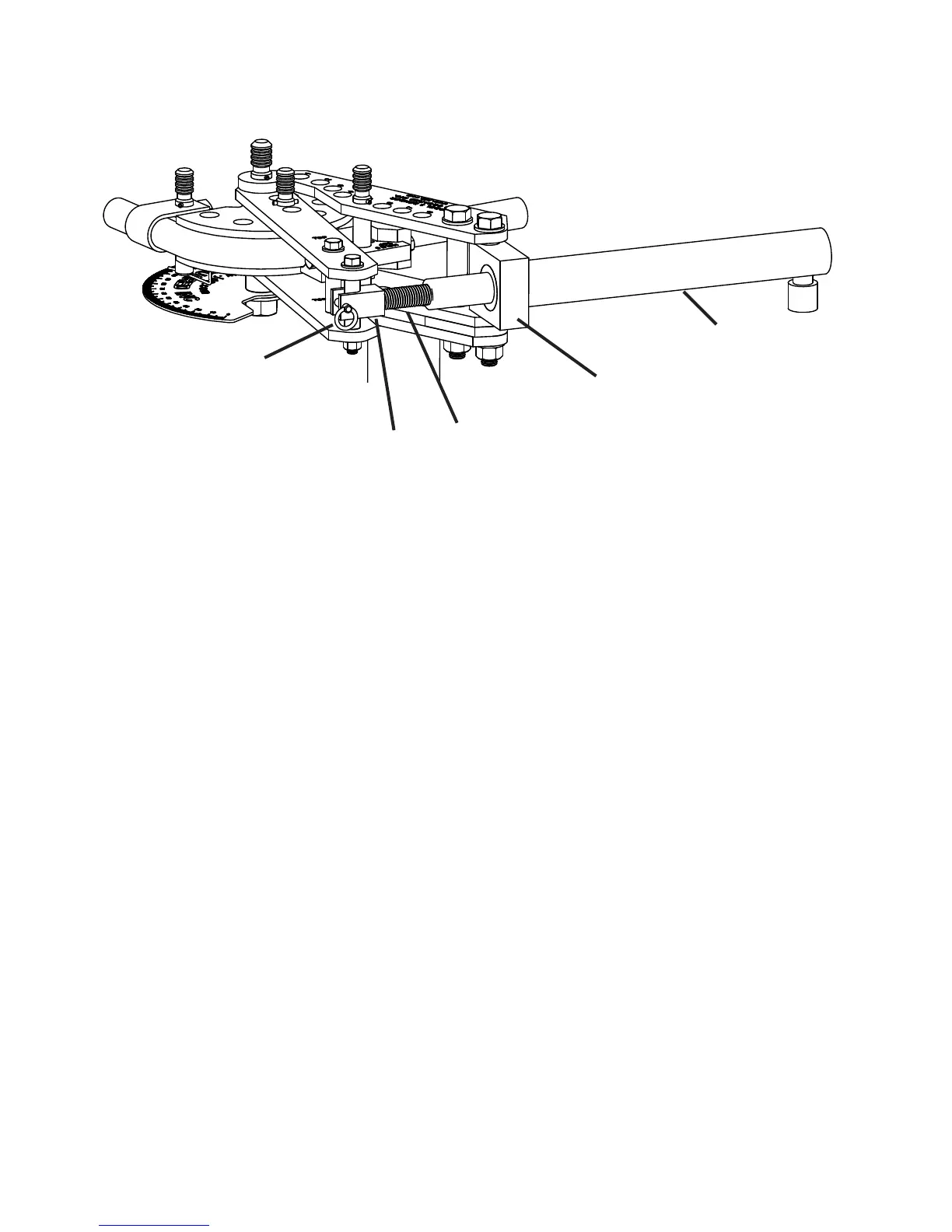

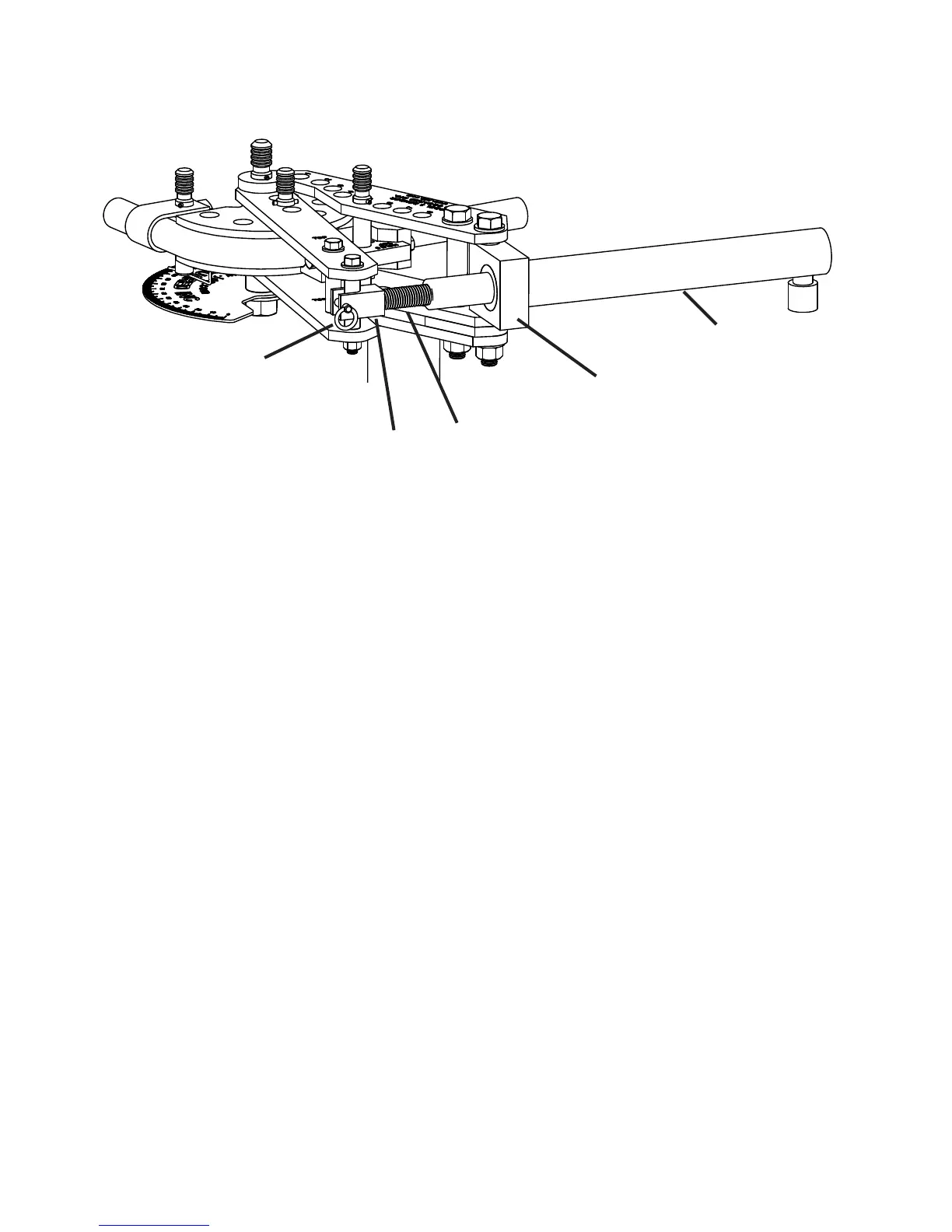

Model 3 Bender Hydraulic Adapter Assembly

Adapter Components: Excludingthehydraulics:

Hydraulic Swivel Block

Yoke

Threaded Extension Rod

Clevis Pin

Recommended Cylinder:

EnerpacRC1014ortheO.T.C.(PowerTeam)Part#C1014Coranequivalentcylinder.Theseporta-powercylindersarerated

at10tonsandhavea14"stroke.Onthefrontofthecylinderisa21/4"x14TPIthread.

Recommended Power Unit:

WeofferseveralhydraulicpumpssuitablefortheModel3Bender.However,anypowerunitmaybeusedthathasanoutput

ofatleast1500-2500PSI.Theaveragebendingpressurewillgenerallybebelow1300PSI.Testedexamples:13/4"x.095"

mildsteel-800PSI,15/8"x.083"4130chromemoly-1300PSI,11/2"solidroundbarstock-3100PSI.Notethattheair-

over-hydraulic10,000PSIpumpsdeliverlessvolumeandthereforebendslowerthantheair-over-hydraulic3,000PSIpumps.

Apressuregaugeishighlyrecommended.Ifthebenderisoperatedatapressurehigherthan2500PSIthefollowbarpinmay

bend. This pin has been designed to be the bender’s weak link and therefore acts as a warning indicator of over loading. In other

words,ifyoubendthefollowbarpin,STOPBENDINGIMMEDIATELY.Forsafereliableoperationdonotoperatethebenderat

pressuresabove2500PSI.

Assembly:

Removetheouter3/4"bolt,sleeveandratchetassemblyfromthebender’sframe.Noticethatthroughthehydraulicswivel

blockismachineda21/4"x14TPIthreadandaslightshoulder.Theshouldershouldfaceawayfromthedrivelinkstowardsthe

rearofthecylinder.Thiswillallowthecylindertobescrewedallthewayushwiththeswivelblock'sfront.Placethepreviously

removed1"ODsleeveintothecylinderswivelblock.Usingthe3/4"bolt,nutandwashers,installtheSwivelblockintothebender

asshownabove.Screwthehydrauliccylinderintotheblockasfarasitwillgooruntilitsfrontsurfaceisushwiththeswivel

block'sfrontsurface.Thequickdisconnectttingontherearofthecylindershouldpointdowntowardsthegroundtorelieve

stressonthehose.Ifitdoesnot,unscrewthecylinderoutoftheswivelblockuntilitdoes,butnofurther.

Ifthecylinderhasastudinstalledintotheendofitsram,itmustberemoved.Thiswillexposeathreadedholeintheendof

theram.ScrewtheThreadedExtensionRodintothecylinder'sramuntilitbottomsout.Now,screwtheYokeontothethreaded

rod until it bottoms out. Rotate the swivel clockwise (to prevent it from unscrewing off the threaded rod) until it may be slid onto

theouter3/4"drivelinksleeveasshownaboveingure5.InstalltheClevisPinthroughtheYoke.

Hookupthepumpandhose.Extendandretractthecylinderseveraltimestopurgeairfromthesystem.

Figure 5 - Bender with hydraulics installed.

10TonHydraulic

Cylinder

HydraulicSwivelBlock

Clevis Pin

Yoke ThreadedExtensionRod

Loading...

Loading...