3) Followbar (Also referred to as the Pressure Die)

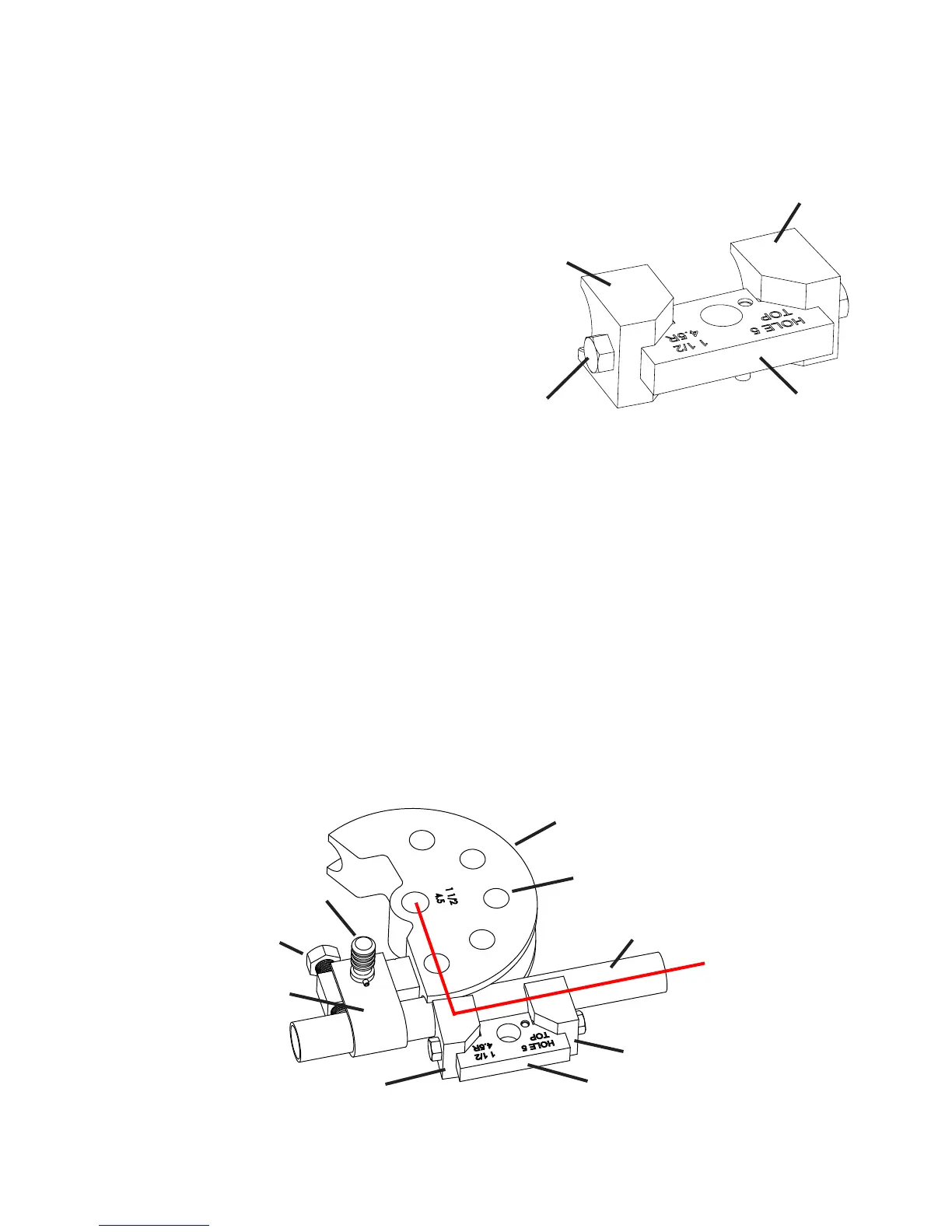

The Followbar is the component that presses the tubing into the forming die to create the bend. Shown in the illustration

below,itconsistsofthreemainparts:abackingblockandtwoinserts.Thismultipartdesignallowstheinserts,ifdamagedor

wornout,tobeinexpensivelyreplacedwithouthavingtopurchaseawholefollowbarassembly.TheInsertsarepermanent

moldcastfromaspecialbearinggradeanti-gallingmaterialtoprotectthetubingfromscratchingduringthebendingprocess

andthenCNCmachinedtosize.TheyaresilverishincolorbutareNOTaluminum.

Notice that one insert is slightly angled. This angle is

calculatedandmachinedintothebackingblockto1/1000

of a degree from theoretically perfect for the tube size

and bend radius. This angle helps to support the tube or

pipeafter thepoint ofbend, greatly reducingattening.

Whenbending,theangledinsertwillalwaysbecloserto

theformingdie,andtheU-strapforthatmatter,thanthe

straight insert.

A5/16"diameterrollpinisinstalledtoholdthefollowbar

in position while loading. When the followbar is in the

bender, theinsert groovesmust ride slightlylower than

the forming die's groove. This allows the followbar to RISE

underpressure.Ifthepinextendedtoofar,thefollowbar

would bind under pressure.

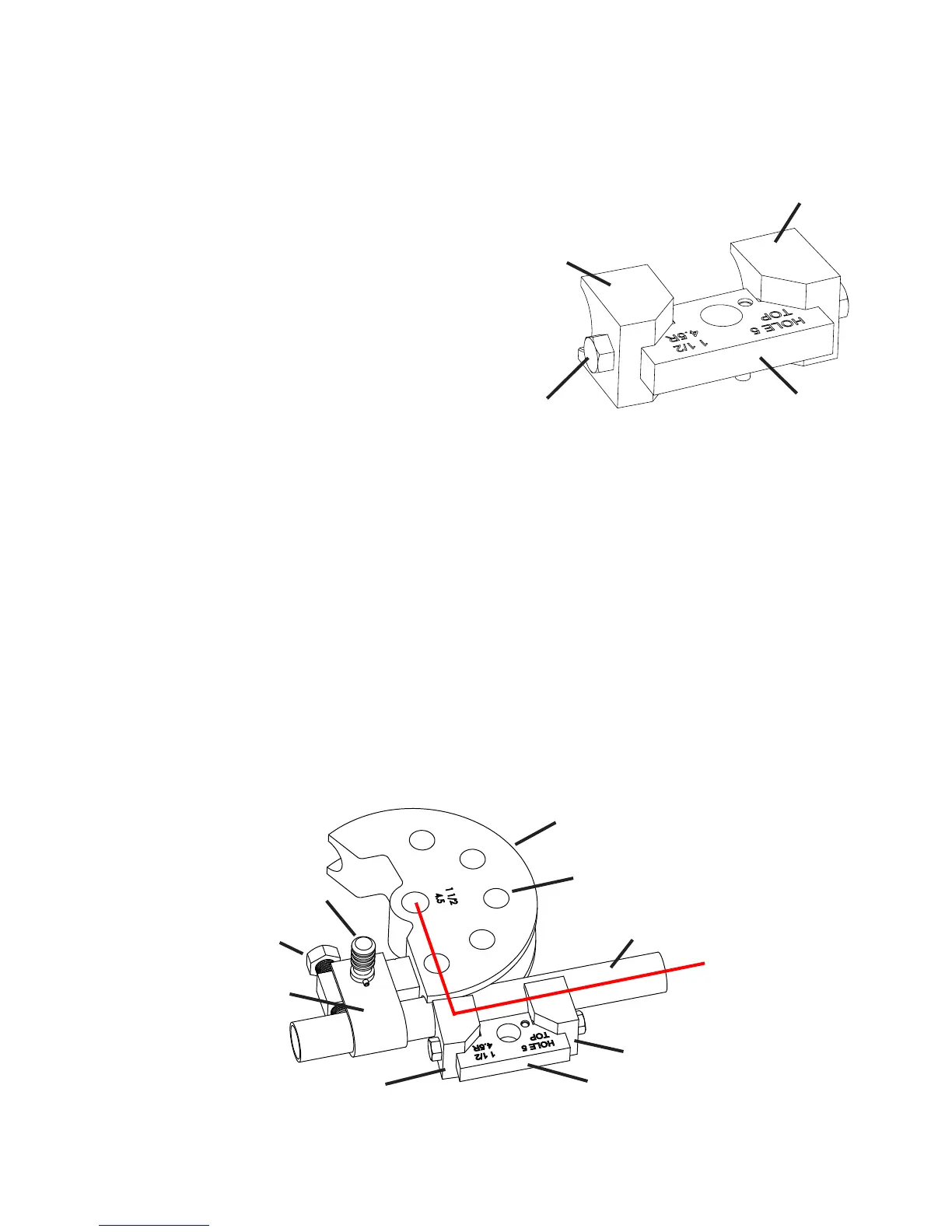

COMPLETEROUNDGROOVEDIESET

Below is pictured all of the components which make up a complete die set for round tubing or pipe. You can see two red

linesdrawnat90degreesapart.Theselinesaremarkedas1and2.Line1runsfromthecenteroftheformingdie'scenter

holetoapproximatelythemiddleoftheangledrearinsert.Line2runsfromthatpointparalleltothetubing.Thisillustrates

the basic principle of how the components relate to each other. It is vital that when bending the rear insert is positioned as

shown.Forexample,supposethefollowbarinengravedwithhole6asshown,butyouinstallitinhole7.Therearinsertwill

be shifted to the right of line 1 and the angle machined into it will have no effect during bending. This will generally cause

atteningofthetubing'soutersideandmayalsocausewrinkling.Ifyouexperiencethisproblemandyouhavethefollowbar

installedinthecorrecthole,therearinsert'sbendingpositioncanbeeasilychecked.Simplyplaceashortpieceoftubinginto

the bender as if your were actually going to bent it. Apply enough bending force to remove any play but not actually bend the

tubing.Nowholda90degreecarpenter'ssquareabovethebendersothatitsoutsideedgesarepositionedsimilartothered

lines shown. The center of the angled rear insert should be roughly at the corner of the square. I say roughly because some

diesaredesignedtoshifttheinsertslightlytotheleftorrightofcentertoimprovebendquality.However,thiswillgenerally

belessthan1/4".Ifasintheexampleabove,youplacedthefollowbarinthewronghole,theinsertwillbeverynoticablyoff

center and almost always to the right of red line 1.

Followbar

Drive holes (5)

U-StrapPin

U-StrapBolt

Tube

Angled Insert

Straight Insert

Figure 10 - Die set components

U-Strap

1

2

Forming Die

- 5 -

Figure 9 - 1 1/2" OD Followbar Assembly

Rear

Angled

Insert

Front Straight

Insert

Backing

Block

1/2"

Locking

Bolts

Loading...

Loading...