ENGINE.

Dimensions.

Bore

87

m.m. (3.43 ins.).

Stroke 111 m.m. (4.375 ins.).

Capacity 3993

C.C.

(243 cub ins.).

R.A.C. rating 28.2 h.p.

Compression ratio 6.8

:

1 (Standard) 7.4

:

1 (Special Head).

Cylinders.

Six cylinders, integral with crankcase. Special cast iron is used and there are

full length water jackets. The detachable cast iron cylinder head carries the valve

gear.

Maximum Rebore.

The maximum permissible rebore

is

bore diameter plus .040 ins.

Crankshaft.

The forged steel counterbalanced crankshaft has a torsional vibration damper

and

is

supported by four detachable "Thinwall" bearings.

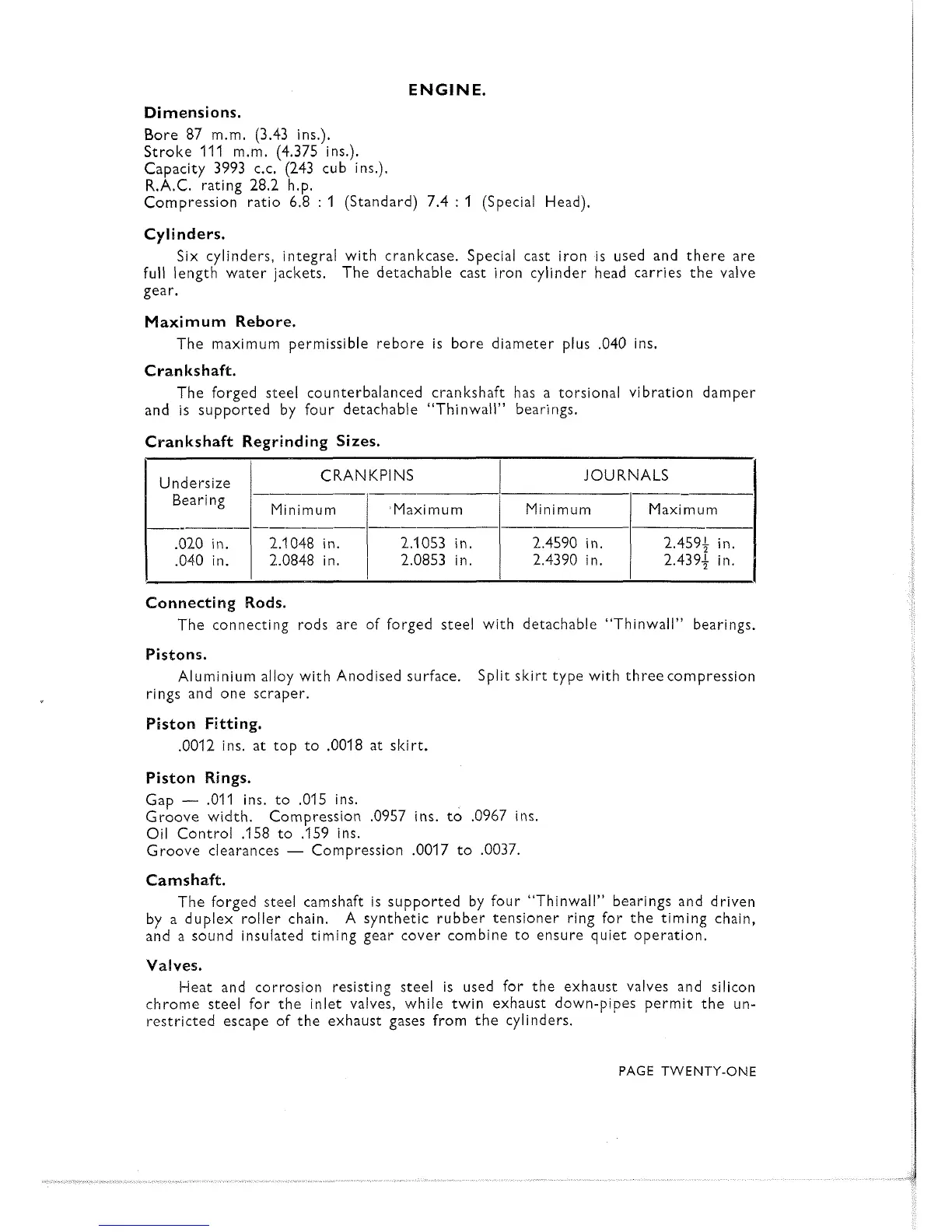

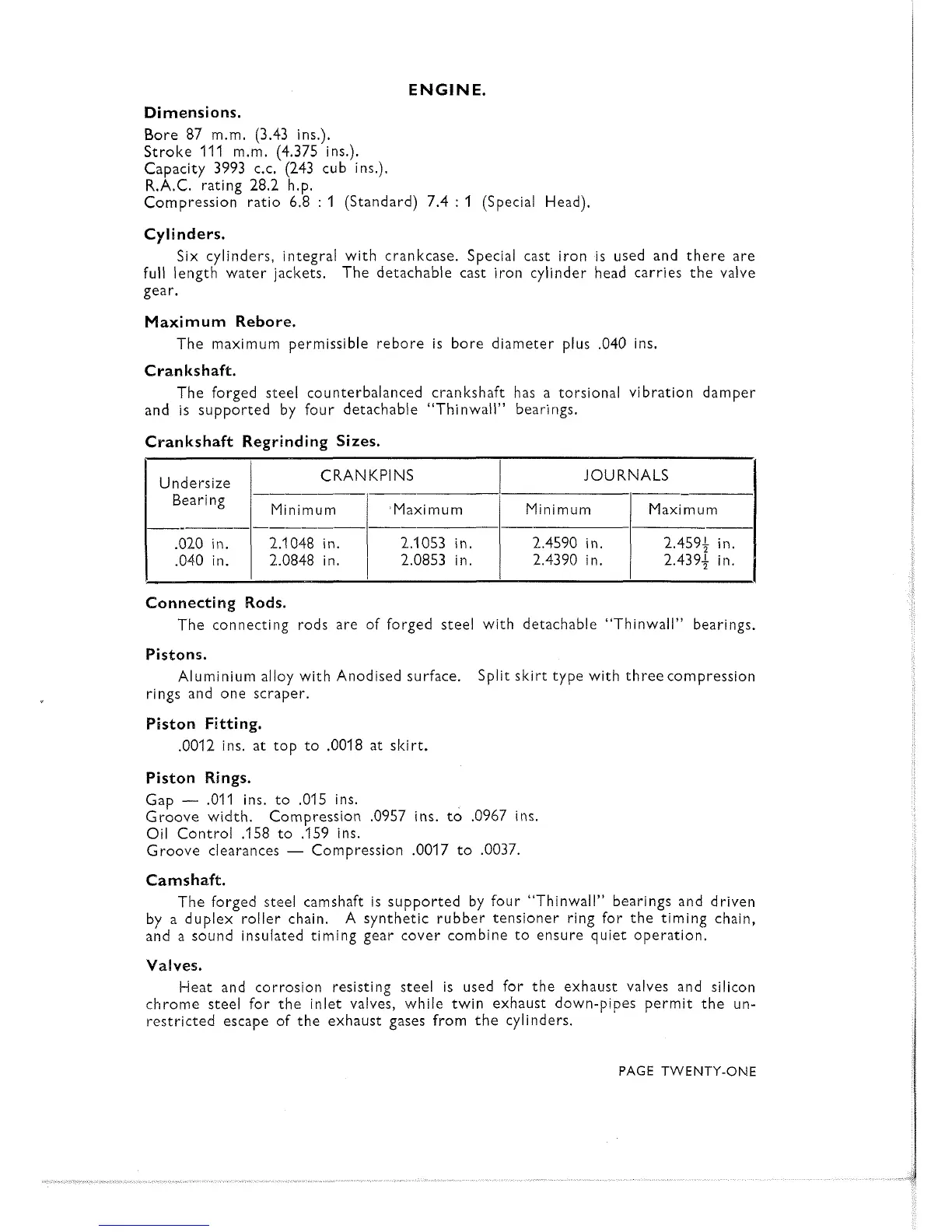

Crankshaft Regrinding Sizes.

Undersize

CRANKPINS JOURNALS

Bearing

--p----

Minimum Maximum Minimum Maximum

-

----

---

.020 in.

2.1

048 in. 2.1053 in.

2.4590 in. 2.4594 in.

.040 in.

2.0848 in. 2.0853 in. 2.4390 in. 2.439; in.

1

Connecting Rods.

The connecting rods are of forged steel with detachable "Thinwall" bearings.

Pistons.

Aluminium alloy with Anodised surface.

Split skirt type with threecompression

rings and one scraper.

Piston Fitting.

.0012 ins, at top to .0018 at skirt.

Piston Rings.

Gap

-

.021 ins. to ,015 ins.

Groove width.

Compression

.0957 ins. to .0967 ins

Oil Control .l58 to .l59 ins.

Groove clearances

-

Compression .0017 to .0037.

Camshaft.

The forged steel camshaft is supported by four "Thinwall" bearings and driven

by a duplex roller chain.

A synthetic rubber tensioner ring for the timing chain,

and

a

sound insulated timing gear cover combine to ensure quiet operation.

Valves.

Heat and corrosion resisting steel is used for the exhaust valves and silicon

chrome steel for the inlet valves, while twin exhaust down-pipes permit the un-

restricted escape of the exhaust gases from the cylinders.

PAGE TWENTY-ONE

Loading...

Loading...