Models EELR538A and EELR539A

Models EELR540A and EELR541A

Installation, Operation and Maintenance

Page 4

Rev. 08/27/2021

15-18000-IOM-W.doc

RECEIVING

The shipment should be thoroughly inspected as

soon as it is received. The signed bill of lading is

acknowledgement by the carrier of receipt in good

condition of shipment covered by our invoice.

If any of the goods called for on this bill of lading are

shorted or damaged, do not accept them until the

carrier makes a notation on the freight bill of the

shorted or damaged goods. Do this for your own

protection.

NOTIFY

Challenger Lifts AT ONCE if any hidden

loss or damage is discovered after receipt.

IT IS DIFFICULT TO COLLECT FOR LOSS OR

DAMAGE AFTER YOU HAVE GIVEN THE

CARRIER A CLEAR RECEIPT.

File your claim with

Challenger Lifts promptly.

Support your claim with copies of the bill of lading,

freight bill, and photographs, if available.

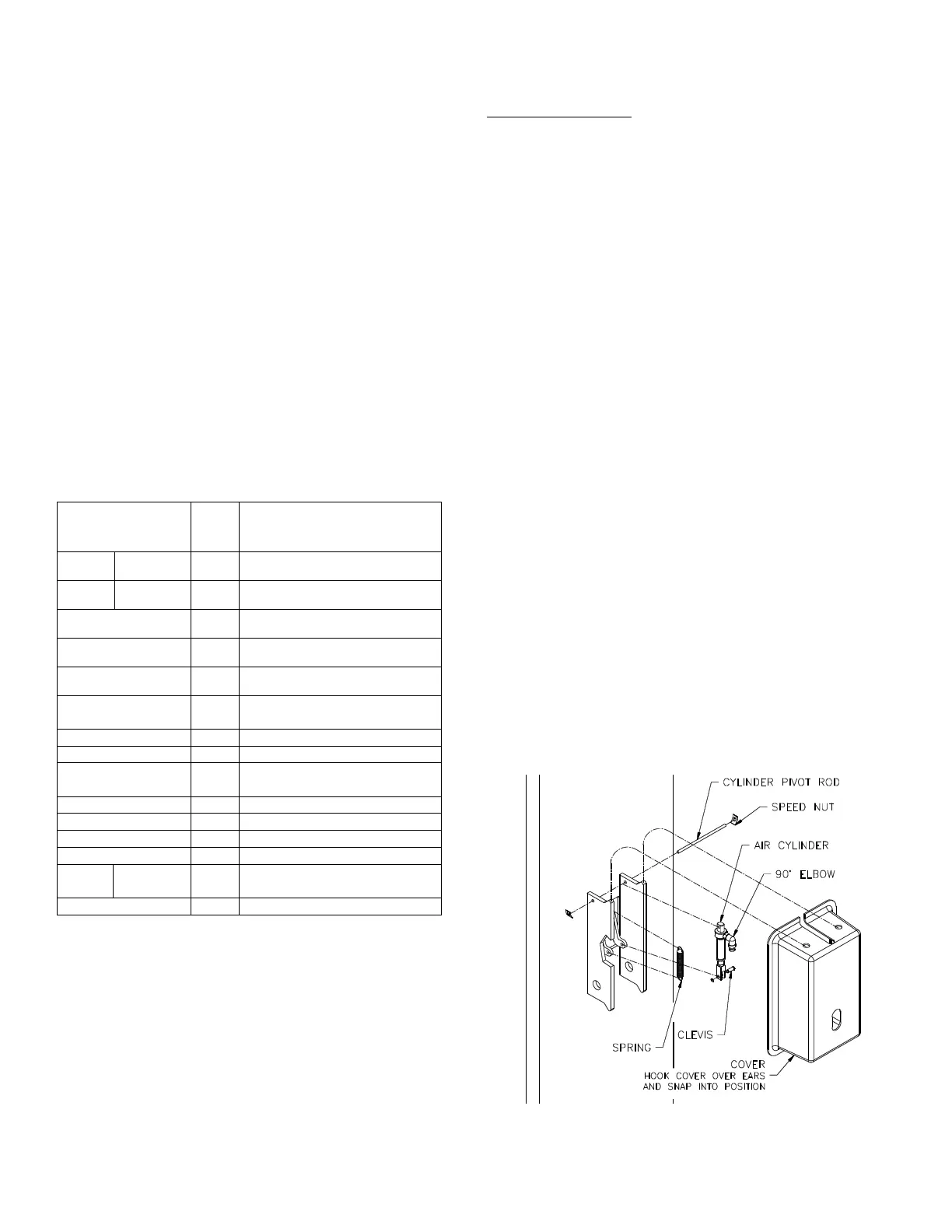

Component Packing List

PART #

QTY/

LIFT

DESCRIPTION

15000 18000

12001 12001-18 1 POWER COLUMN ASS’Y

12002 12002-18 1 IDLER COLUMN ASS’Y

12004 1 OVERHEAD PACK

15-18000-HW-W 1 HARDWARE BOX

B12048S-1 4 ARM ASSEMBLY

12102

2

COLUMN EXT. (14’-6” O.A. HT.)

12022 COLUMN EXT. (16’-6” O.A. HT.)

12074 1 OVERHEAD SHUTOFF BAR ASS’Y

12045 1 OVERHEAD LIMIT SWITCH

12100

2

SYNC. CABLE ASS’Y (14’-6”)

12019 SYNC. CABLE ASS’Y (16’-6”)

B12069 4 ADAPTER EXTENSION (4”)

B12068 2 ADAPTER EXTENSION (8”)

12071 2 ADAPTER RACK

12093 4 ARM RESTRAINT ASSEMBLY

12119 12087-19

1

POWER UNIT – SINGLE PHASE

12089 12089-19 POWER UNIT – THREE PHASE

15-18000-LP-W 1 LITERATURE PACK

ACCEPTED OILS – Do not use oils with detergents

Hydraulic fluid is not provided with the lift shipment

-10

wt. anti-foam, anti-rust hydraulic / biodegradable oil

-Dexron III ATF

INSTALLATION

SAFETY REQUIREMENTS FOR INSTALLATION AND

SERVICE

Refer to ANSI/ALI ALIS (current edition)

I

MPORTANT: Always wear safety glasses while installing lift.

TOOLS (MINIMUM REQUIRED)

a. Tape measure, 16ft

b. Chalk line

c. 4ft level

d. 10” adjustable wrench

e. Standard open end wrenches 7/16”, 1/2",

(2) 9/16”, (2) 11/16”, 3/4"

f. 5/16” allen wrench

g. Needle nose pliers

h. Hammer drill with 3/4” diameter carbide tipped

bits

i. 2 lb hammer

j. Torque wrench: 150 foot pounds minimum with 1

1/8” socket

k. 12 ft. Step ladder

l. Anti-Seize lubricant (for arm pins and foot pad

screw threads and stop rings)

L

AYOUT

1) Layout the service bay according to the

architect’s plans or owners instructions (see Fig.

1b). Failure to install in this orientation can

result in personal and property damage. Be

certain that the proper conditions exist, see page

3.

2) Assemble column extension to column using

3/8”-16 x 3/4" lg Hex flange head bolt. Repeat for

opposite column and extension.

3) Erect and align both column assemblies.

L

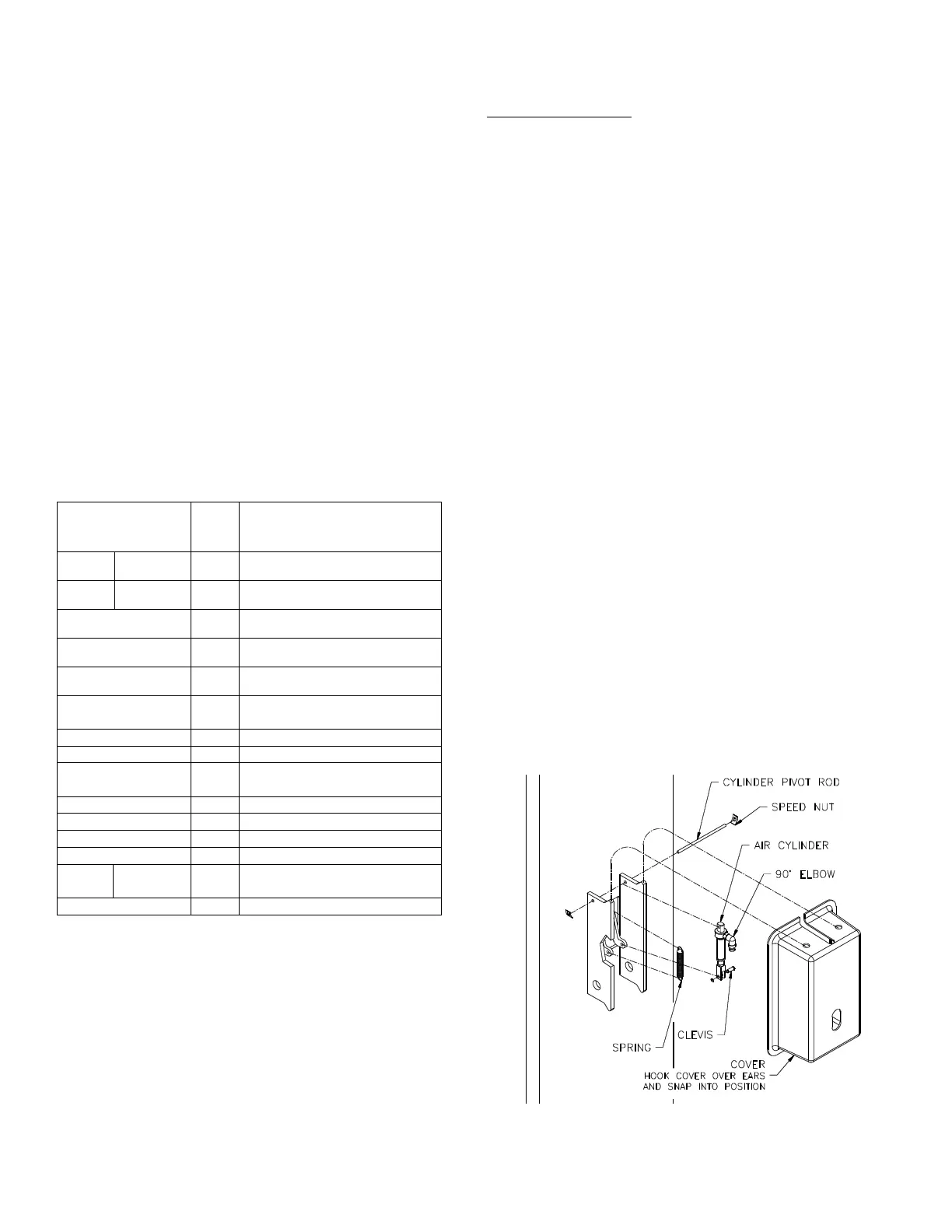

OCK RELEASE/PAWL

Fig. 2 – Locking Pawl Assembly

Loading...

Loading...