RT655 Operator’s Guide

OG6:10

Chapter - Routine Maintenance

Page Issue A

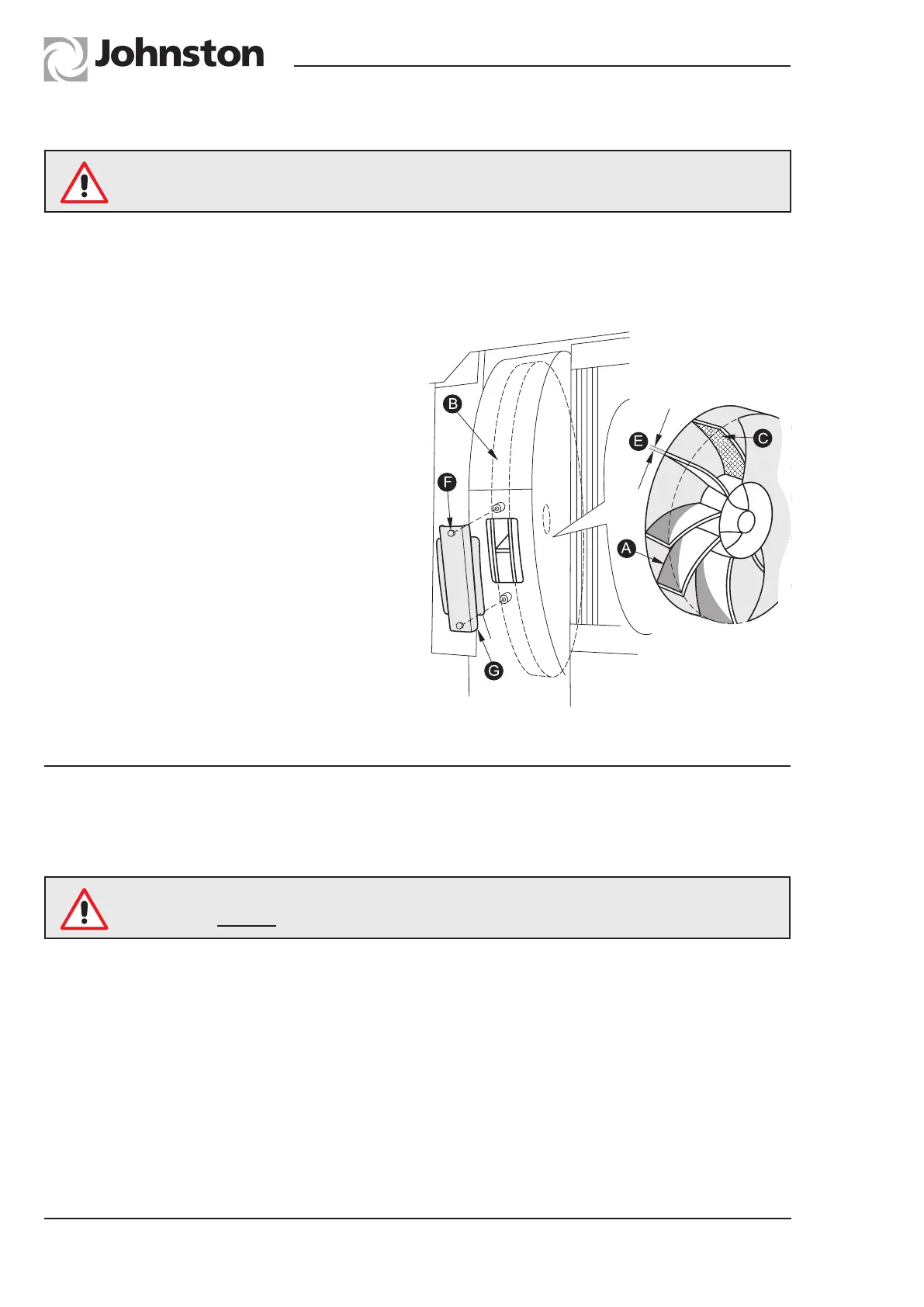

Suction Fan Impeller and Casing

In operation the impeller and casing can be subjected to wear in the form of erosion

resulting from dust or small abrasive particles passing through the fan system and must

be inspected as instructed in the Weekly Maintenance Schedule.

In cases where excessive dust could pass through the system, these inspections should be made

more frequently, the blades should be clean of any debris (C) to prevent dirt build up and premature

failure due to vibration.

Remove the 2 setscrews (F) and remove

the inspection plate (G). The impeller blades

can be seen through the inspection port and

the blades cleaned with a scraper (part no.

283665-1) if required.

If the impeller is subjected to excessive wear,

disintegration could occur whereby the front

shroud plate detaches itself from the driving

plate as a result of the high rotational forces

within the component. Any wear occurring to

the impeller is usually shown up as a thinning

of the blades generally in a broad wear pattern

(A). Once apparent thinning of the impeller

blades is observed, the component must be

replaced when any blade thickness (E) is

less than 2mm. If perforation of the fan case

is observed (B) due to wear erosion, this

component should also be replaced to prevent

pollution of the fan compartment with dust.

Refit the inspection plate securely after inspection / cleaning.

Filter Screens and Roof Duct

The body filter screen (Item 15, Fig.1) and roof duct must be kept clean, otherwise suction

performance can be affected. The screen can be cleaned in situ, but it is preferable to remove it.

To remove, release the linch pin, which will allow the screen to swing down, disconnect the air pipe

to the mesh shaker unit if fitted. The screen can then be lifted out of the hooks on the rear sloping

panel for thorough cleaning. Also hose out the roof ducts to ensure they are clean while the filter

screen has been lowered.

Ensure the auxiliary engine is not running and isolated before fan maintenance

or replacement is attempted.

The fan impeller is finely balanced as an assembly in manufacture.

NEVER remove or replace the hub, or carry out repairs to it.

Loading...

Loading...