– 1 –

Model DSC-244 DSC-244V

Type of sewing

machine head

Cylinder-bed, 1-needle, unison-feed lockstitch

machine

Cylinder-bed, 1-needle, unison-feed lockstitch

machine (horizontal drop feed)

Usage Suited for sewing medium-to heavy weight materials

Sewing speed Max. 2,200 sti/min

Stitch length 0 to 6 mm

Lift of presser foot Hand lifter

:

9 mm

、

Knee lifter

:

15 mm

Thread take-up lever Slide type thread take-up

Needle bar stroke 36 mm

Needle to be used GROZ-BECKERT 135×17 Nm90 to Nm130

(

Standard Nm110

)

Needle system #50 to #20

Stitch adjusting method Dial

Lubrication method By an oiler and an oil wick centralized in face plate

Motor to be used 400W Electro-stop motor (4P)

Oil to be used New Defrix Oil No.1

Noise - Equivalent continuous emission sound

pressure level (L

pA

) at the workstation :

A-weighted value of 83.5 dB; (Includes K

pA

=

2.5 dB); according to ISO 10821- C.6.2 -ISO

11204 GR2 at 2,200 sti/min.

- Sound power level (L

WA

) ;

A-weighted value of 89.5 dB; (Includes K

WA

= 2.5 dB); according to ISO 10821- C.6.2

-ISO 3744 GR2 at 2,200 sti/min.

- Equivalent continuous emission sound

pressure level (L

pA

) at the workstation :

A-weighted value of 80.0 dB; (Includes K

pA

=

2.5 dB); according to ISO 10821- C.6.2 -ISO

11204 GR2 at 2,200 sti/min.

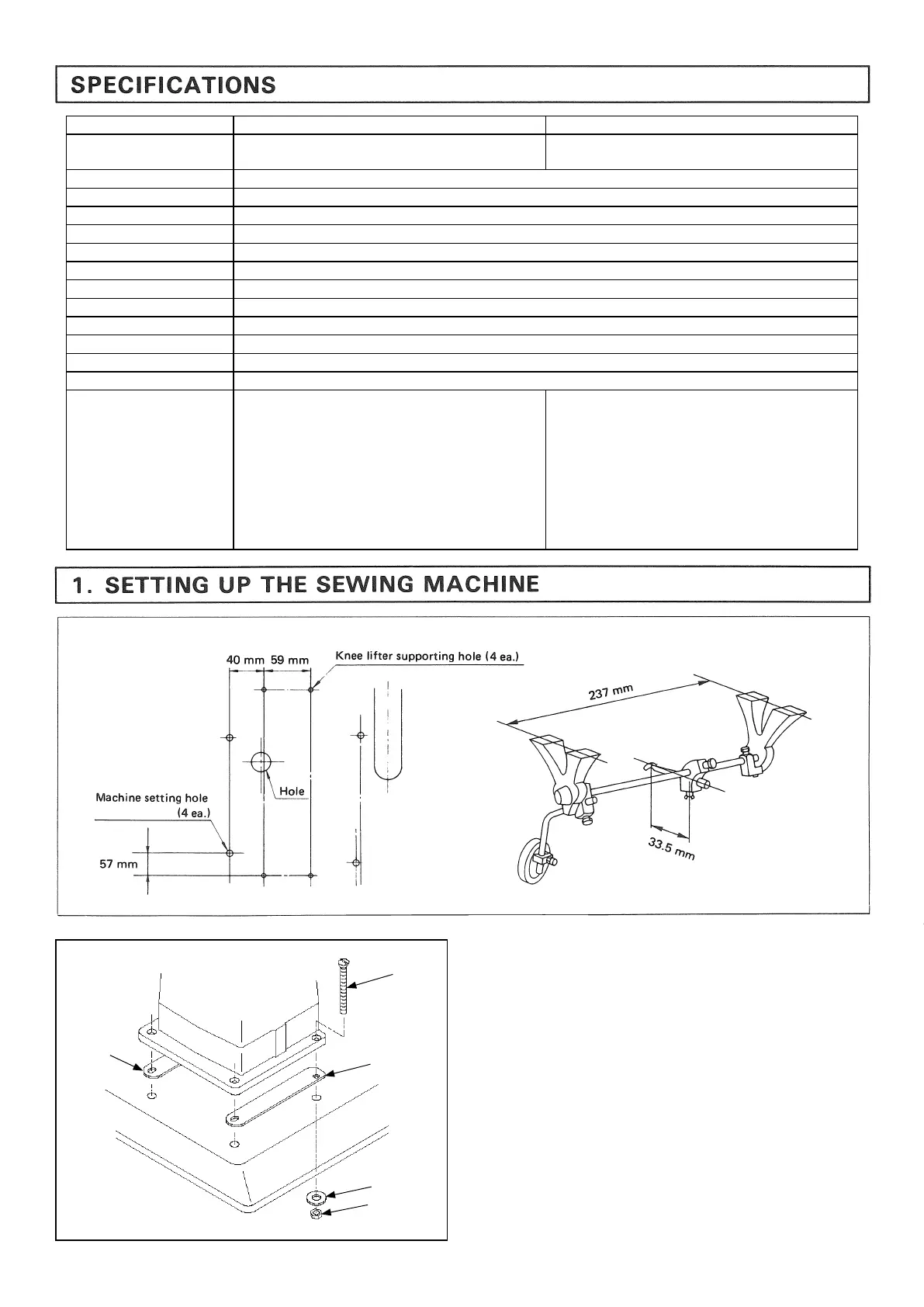

1. Mounting position of the knee lifter

(Caution) The knee lifter should be mounted before the

moter is installed.

2. Carry the sewing machine with two persons.

(Caution) Do not hold the handwheel.

3. Do not put protruding articles such as the screwdriver and

the like at the location where the sewing machine is placed.

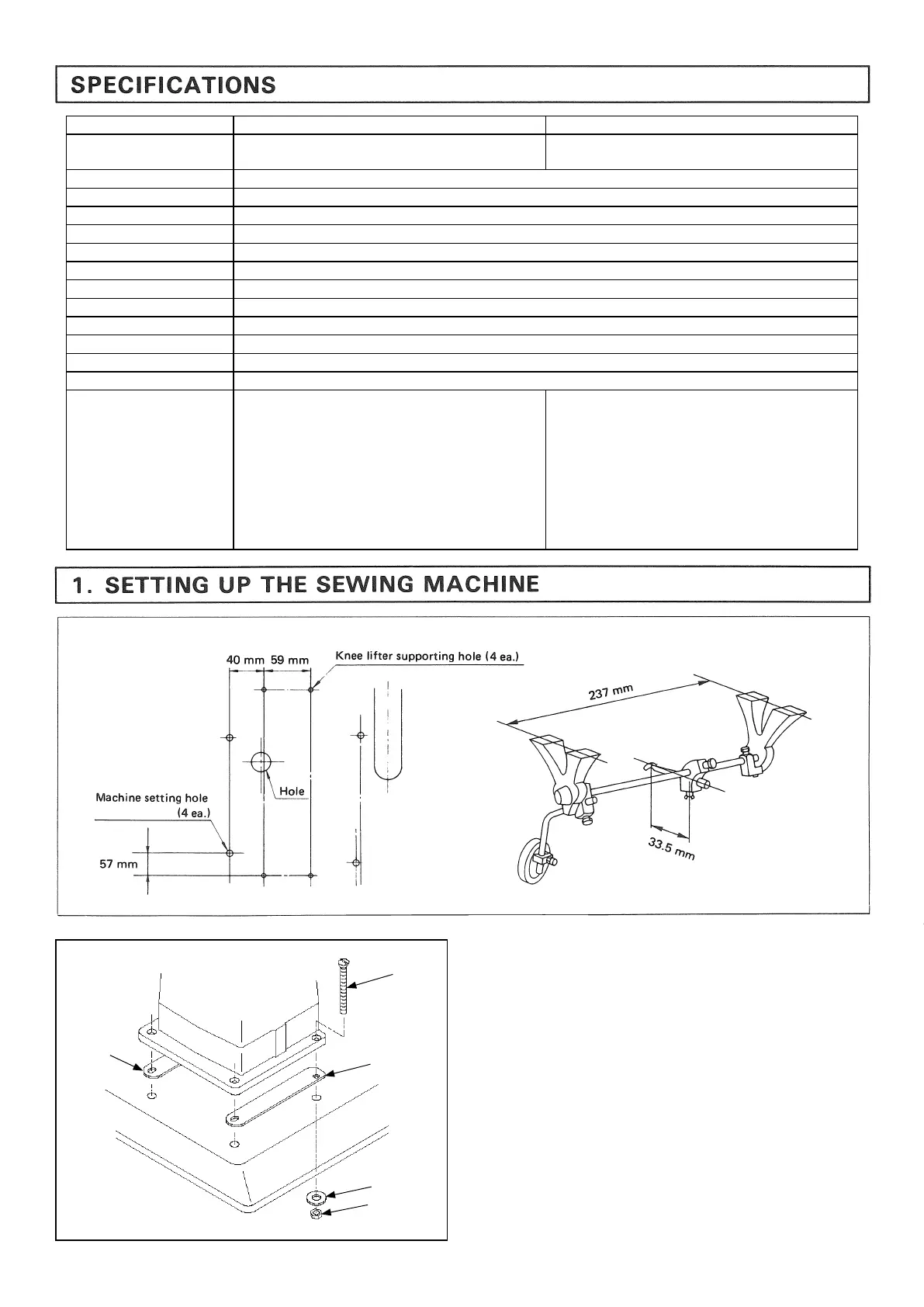

4. Setting the sewing machine

Holding countersunk screw

1

, washer

2

and nut

3

supplied

with the unit, fix the sewing machine on the table with

aligned with rubber packing

4

at four locations.

5. Securely attach head support rod to the table until it goes no

further.

1

4

2

3

4

Loading...

Loading...