– 53 –

o If the clearance is larger than the

specified value, detection failure

may result.

o If the clearance is smaller than

the specified value, the knee-

lifter detection seat (asm.) may

interfere with the knee-lifter

sensor , resulting in breakage

of the sensor.

o If the amount of play is 0 mm or

holding the components with an

excessive pressure, the knee-

patch plate (asm.) may

maloperate.

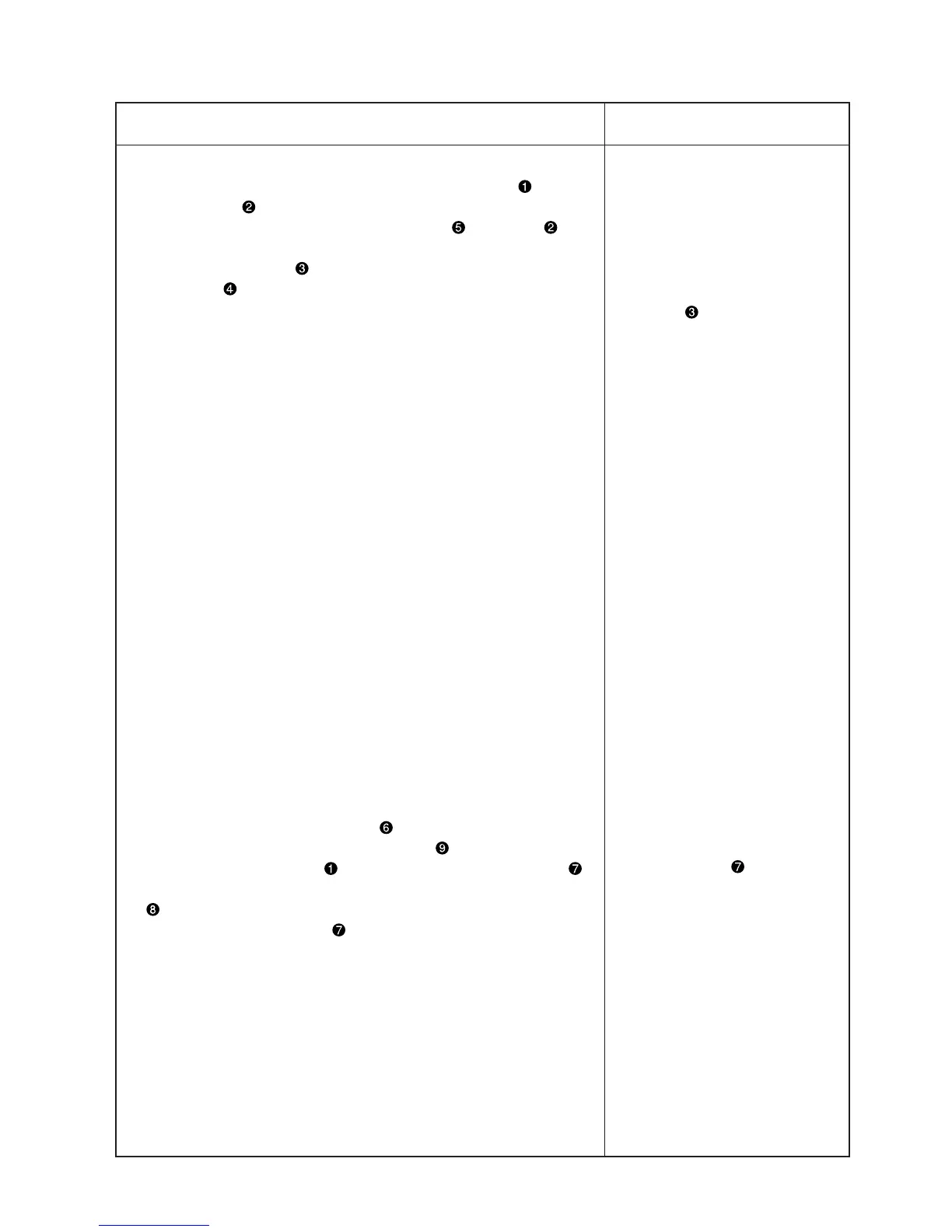

1) Assembling the knee-lifter detection sensor plate (asm.)

1. Remove the knee-lifter plate vertical shaft installing arm and the

two setscrews that are temporarily fixed on the bottom cover.

2. Attach knee-lifter detection sensor plate (asm.) with screw at a

position where a 0.5 to 1.0 mm clearance is provided between knee-

lifter detection sensor and the periphery of knee-lifter detection

seat (asm.) .

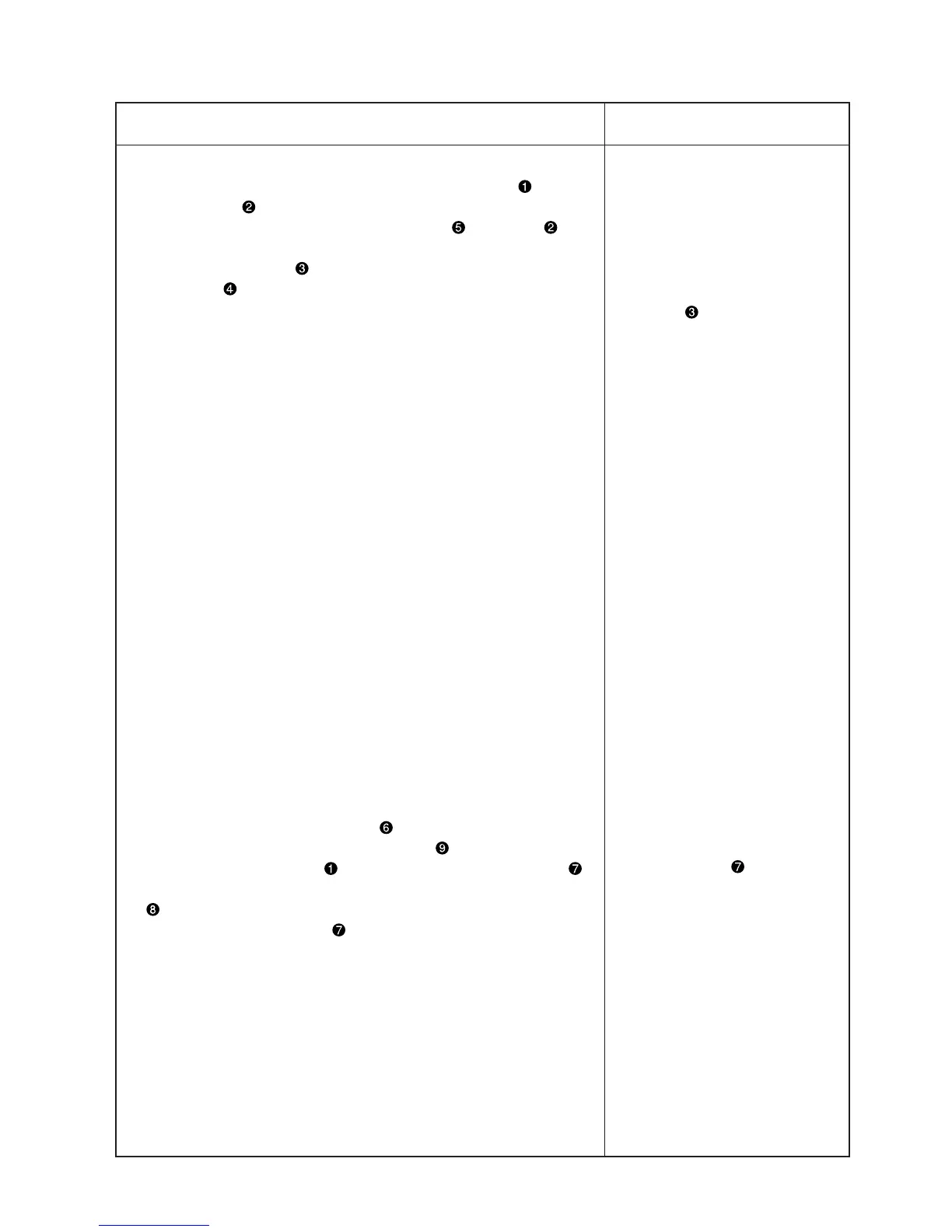

2) Assembling the knee-patch plate (asm.)

1. Apply the knee-lifter working shaft to the boss end plane of the

bottom cover, and fasten it with the setscrew by pinching the knee

vertical shaft mounting arm provided with the knee-patch plate .

Adjust the play of the axial direction of the knee-patch horizontal shaft

to approximately 0.2mm.

2. Check that knee-patch plate smoothly move.

Adjustment Procedure

Results of Improper Adjustment

Loading...

Loading...