3

1115.GB

Charging electronics extra option

(Aquamatic)

Z

The Aquamatic serves to control an

external solenoid valve of an automatic

water refilling system.

When a cell voltage of 2.4 V/cell is reached,

a relay contact (normally open contact,

contact rating 5 A) is triggered by the

following pulse train:

- 6-7 pulses with a duration of 3 sec., then

maintained contact for 7 min.

The contact is potential-free, a 230 V power

connection of the battery charger is

available.

Electrolyte circulation:

Z

The charger has an option for controlling an

electrolyte circulation pump.

M

Observe the respective manufacturer’s

guidelines! It should only be connected by

the manufacturer’s service department.

The Aquamatic and electrolyte circuluation

systems are monitored. Any faults are

displayed on the front panel.

M

The connection of external additional

equipment may only be carried out by

skilled electricians.

Z

To attach additional external equipment,

contact the manufacturer’s service

department.

Charging curve / pulse charging:

-T

1

= Battery gassing phase reached.

Start of the recharging phase

-T

2

= Start of the pulse charging phase

(1-5 pulses depending on the main

charging time)

-T

3

= End of battery charge.

Z

If the battery remains attached to the

charger at the end of the charging time

(T3), there will follow an 8 minute trickle

charge every 8 hours and after 24 hours a

one-off compensation charge lasting

2 hours.

Characteristic curve:

Wa Charging characteristic

Uz Cell voltage (V/cell)

I

L

Charging current

(in % of rated current)

I

dN

Rated battery current

The curve of the Wa characteristic is

determined by points 1), 2) and 3):

1) 100 % I

dN

at V = 2.0V/cell

2) 50 % I

dN

at V = 2,4V/cell

3) 25 % I

dN

at V = 2,65V/cell

Z

A controlled thorough acid mixing by means

of current pulses is carried out at the end of

the recharging phase.

T

U, I

T1

T2 T3

2,8V

2,6

2,4

2,2

2,0

1,8

2,65

0 25 50 75 100%

1)

2)

3)

I

L

/ I

dN

U

Z

14

1115.GB

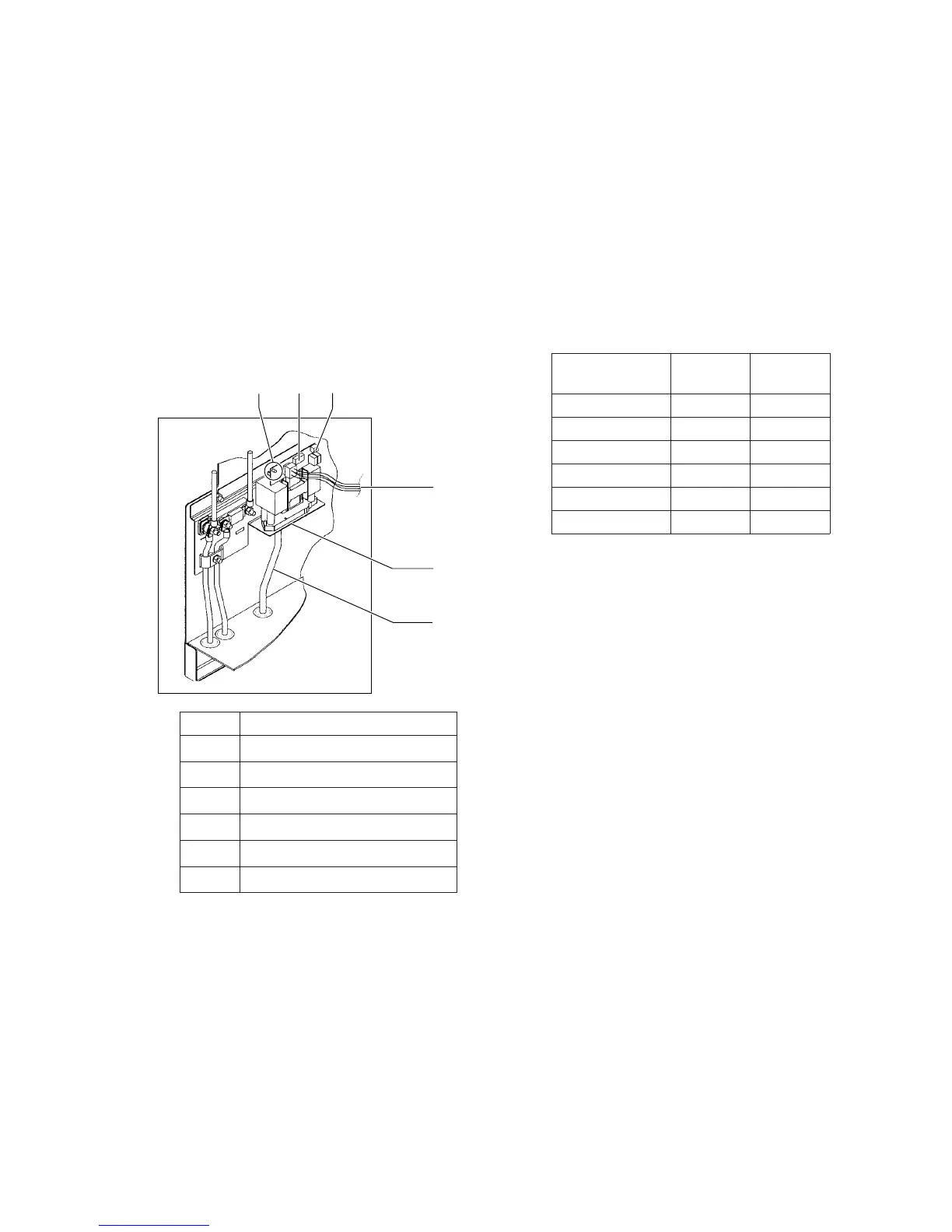

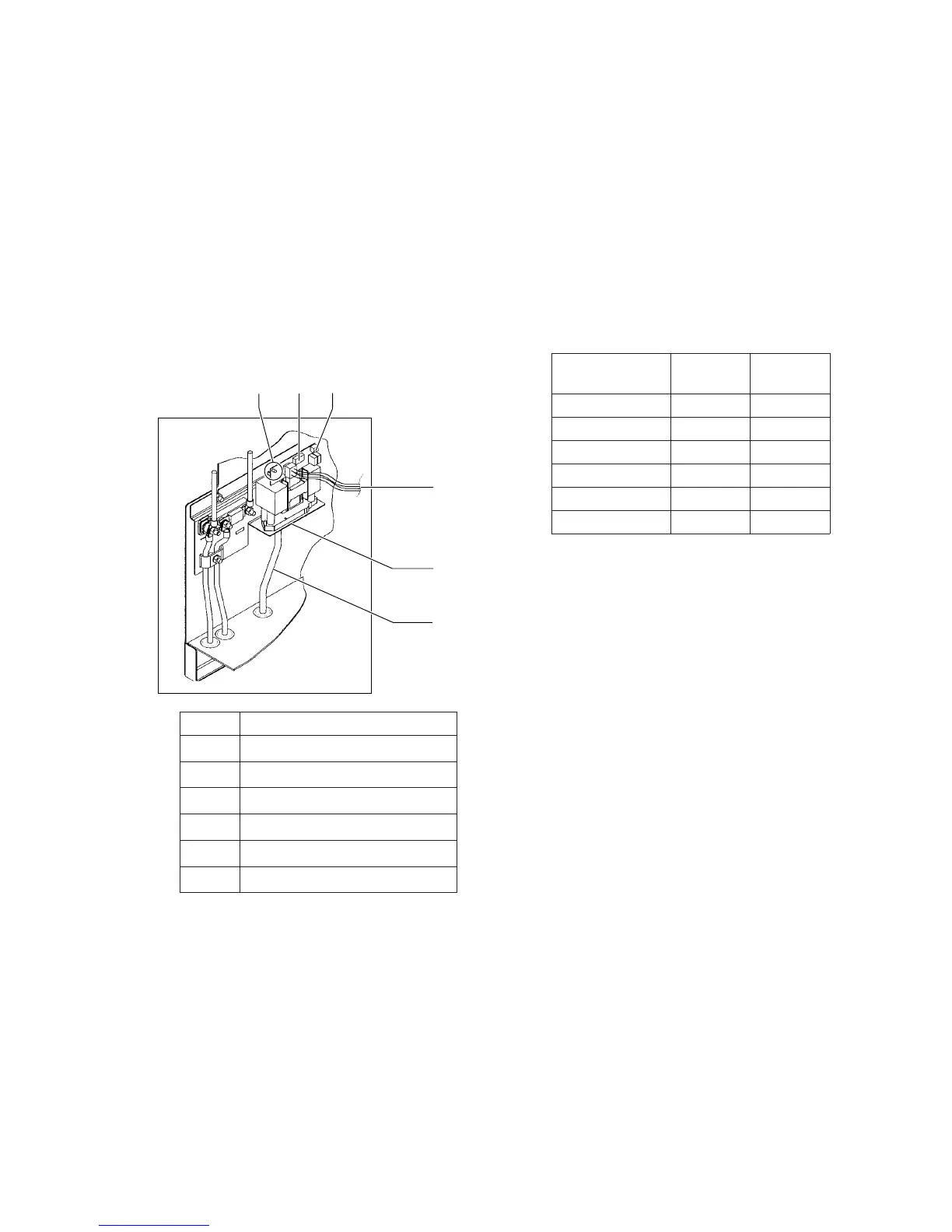

The internal electrolye stirrer consists of the

following parts:

- An additional switch contact to switch on

the pump;

- A sensor to switch or adapt the charging

factor;

- A membrane pump with an air filter and

air pressure monitor. The pump delivers

a constant pressure of 100 mbar and

overcomes an acid level of ca. 80 cm in

the main charging phase;

- A connecting hose with an air plug

connection in the pilot contacts of the

charging connector.

Air pressure monitor:

If the system is working correctly and the

recharging time is reduced, the green

LED (1) is lit on the control board.

Z

A defective hose system can be identified

via the air pressure monitor. Service

message flashes: (4x / break / 4x).

Air volume flow:

The air volume flow can be adjusted within

the range of 2 l/min to 12 l/min. It is

independent of the hose system and thus of

the number of cells.

The air volume flow can be set according to

requirements with the switch (3):

Item Description

1

Green LED

2

Fuse (1 AT)

3

Switch

4

Cable to the charging switch

5

Filter

6

Air hose

12

3

4

Loading...

Loading...