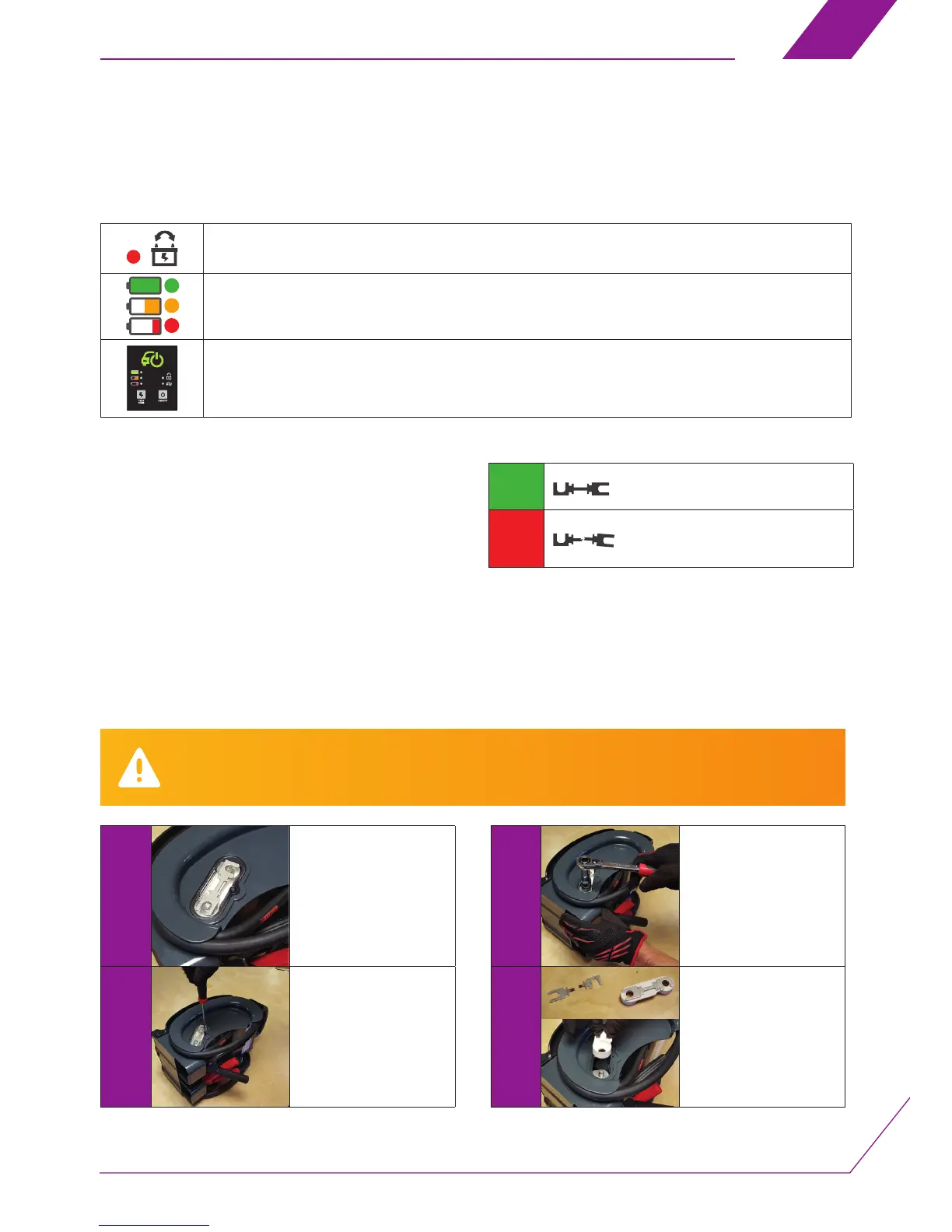

During this operation, the Kap’SAM® must not be connected a vehicle or to any voltage source.

The cables and clips must be stowed in the compartment provided. During this operation you must wear safety glasses.

1

Position your Kap’SAM®

with the side facing you

as shown in the photo

opposite.

2

Unscrew the screw in the

fuse compartment cover

using a suitable Phillips®

screwdriver.

3

Unscrew the nuts fastening

the fuse holder with a 17

mm socket, starting with

the lower one on the left.

4

Replace the fuse

(reference: XCAP-FUSE)

and position it as shown

opposite using protective

gloves.

5. Diagnosis and explanation of alerts displayed

by the Kap’SAM®

6. Replacing the fuse

Indicators

Polarities reversed. Connect the Kap’SAM®’s clips to the right polarities and begin the starting procedure again.

The three state of charge indicators ash. Your Kap’SAM® is connected to a source

with too high a voltage (e.g. 24 Volts). Disconnect the Kap’SAM® to avoid damaging it.

No indicator lights up when you connect the Kap’SAM®.

The battery is deeply discharged (cf. paragraph on Forced Start Mode)

Your Kap’SAM® is connected to the broken down vehicle, the start

indicator is on following the vehicle start procedure (see paragraph

on Starting a vehicle).

• Check the Kap’SAM®’s state of charge (see paragraph Testing the

Kap’SAM®’s state of charge)

• If the state of charge is not satisfactory, recharge the Kap’SAM®

(see paragraph on Recharging the Kap’SAM®).

• If the state of charge is satisfactory, check the state of the general

fuse.

If these checks do not result in your in your Kap’SAM® restarting,

please contact our technical assistance department without delay.

(See Warranty paragraph).

OK

BLOWN

Replace with the second fuse supplied

with the device

Functions: Quick check procedure

EN

1110-

Loading...

Loading...