I_

NEEDLE BAR HEZGHT

REVILED SIC

Oct. 84 I - 1

+ ommm,L KJy, s4

PAO! l

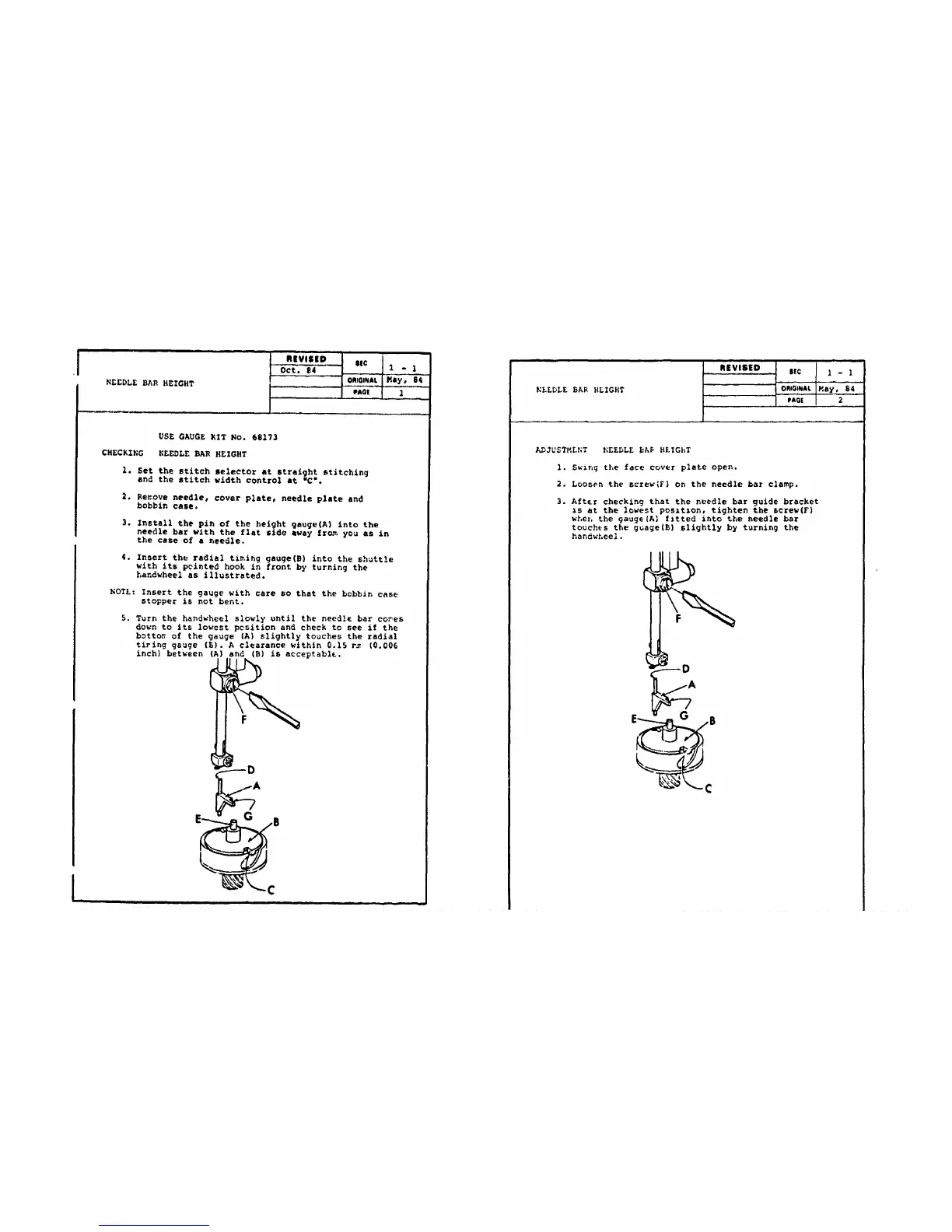

USE GAUGE KIT No. 68173

CHECKING NEEDLE BAR HEIGHT

le

2.

Set the stitch selector at straight stitching

and the stitch width control at "C'.

Re_ove needle, cover plate, needle plate end

bobbin case.

3. Install the pin of the height gauge(A) into the

needle bar with the flat side away fr_. you as in

the case of a needle.

4. Insert the radial t_ing gauge(B) into the shuttle

with its pclnted hook in front by turning the

handwheel as illustrated.

NOTE: Insert the gauge with care so that the bobbin case

stopper is not bent.

5. Turn the handwheel slowly until the needle bar co_es

down to its lowest position and check to see if the

botto_ of the gauge (A) slightly touches the radial

tiring gauge (_). A clearance within 0.15 r_ (0.006

inch) between (A) and (B) is acceptabl_.

F

G

NELDLE BAR HEIGHT

REVISED

$sc 1 - 1

ORIGINAL May, S4

PAG[ 2

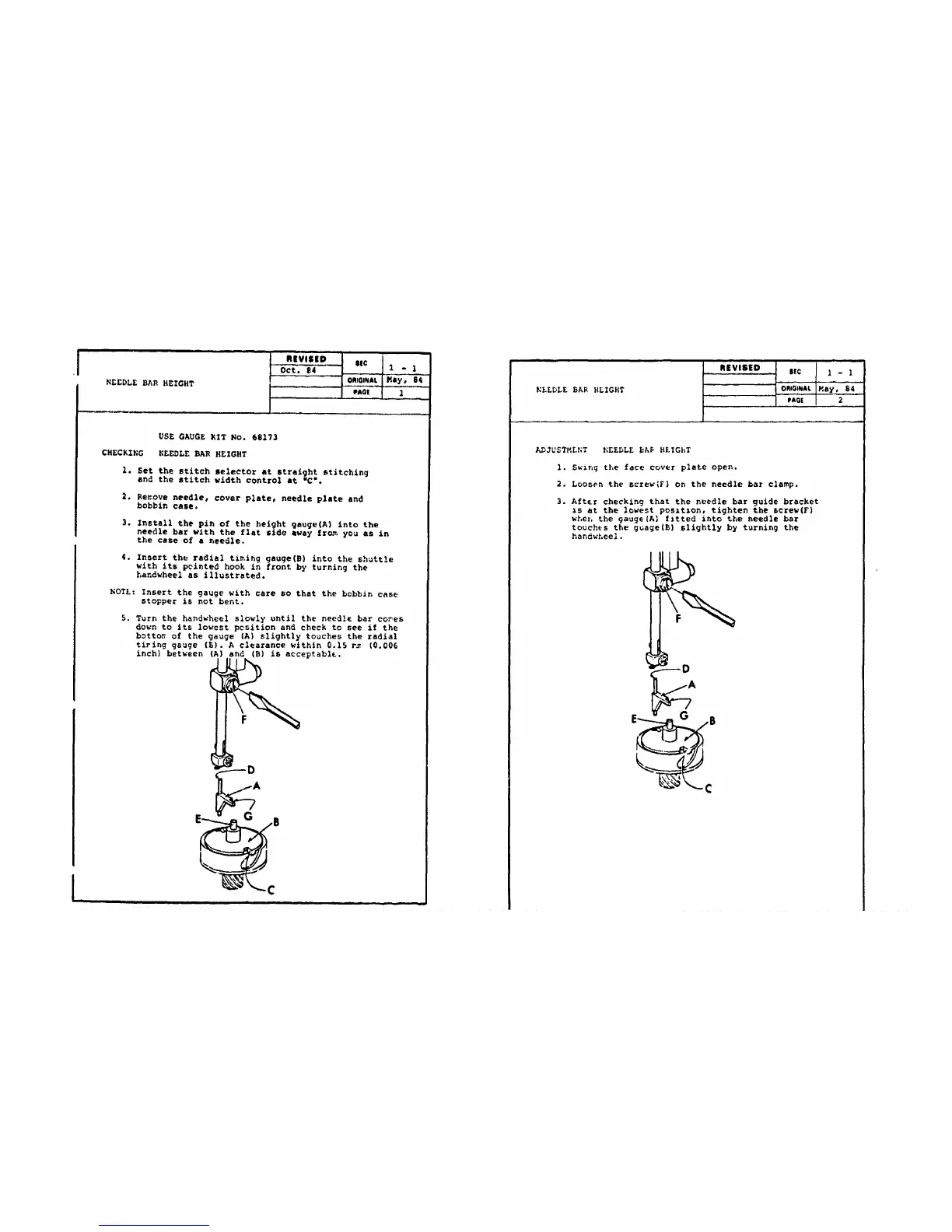

ADJUdTHLNT _EEDLE _A% HE%GhT

1. Swlng the face cover plate open.

2. Loosen the screw(F} on the needle bar clamp.

3. After checking that the needle bar guide bracket

_s at the lowest pos_t_on, tighten the screw(F)

whet, the gauge(A_ f;tted into the needle bar

touches the guage{E) slightly by turning the

hsndwheel.

LD

G

¢

, ,, ................ iII i iii , ,,.,.

Loading...

Loading...