4-6

90-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

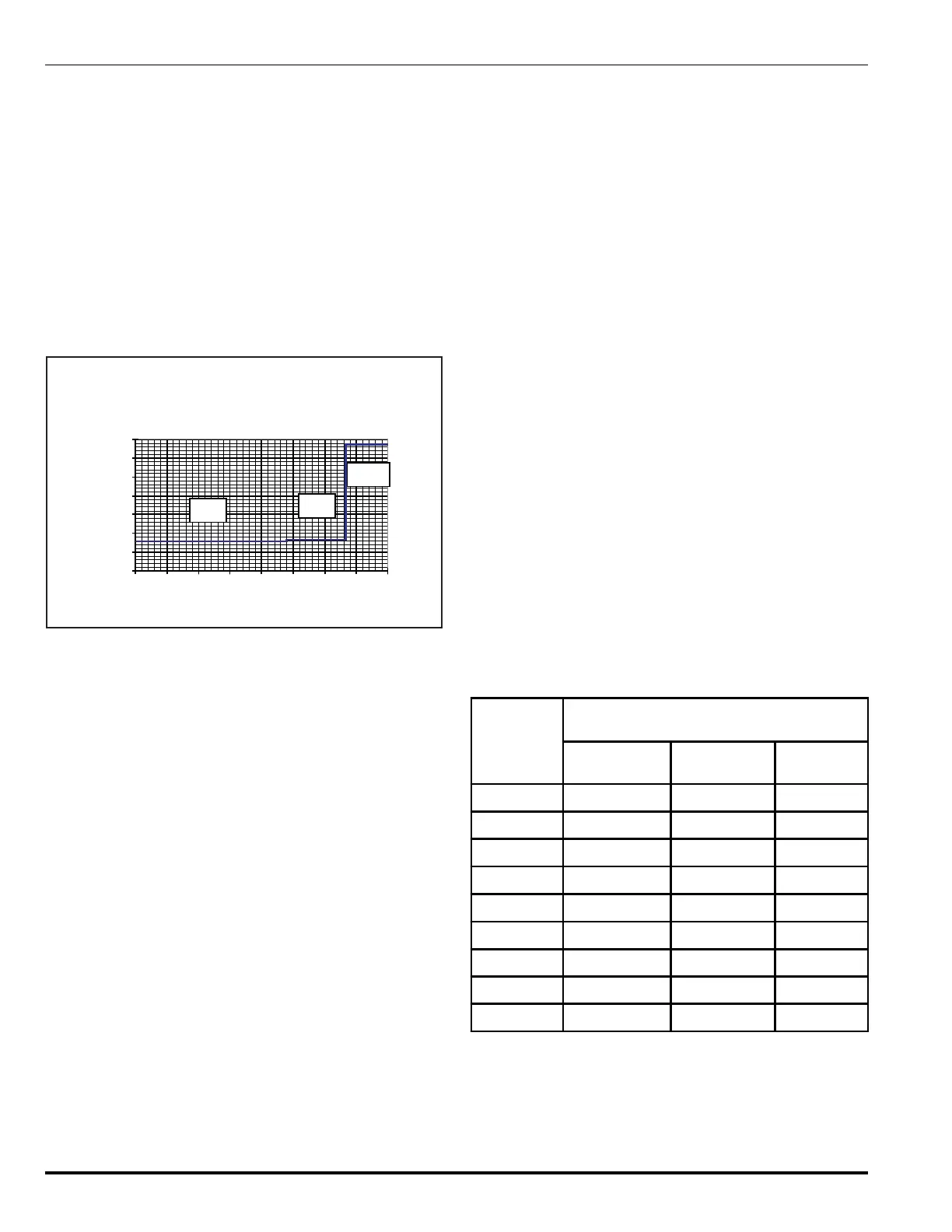

4-2.3.1 FIRST BRANCH FLOW SPLIT

To assure accuracy of the flow calculations, there are

various agent flow limits. The maximum % agent in pipe

for all systems is 80%. There is a limit on the allowable

percent of agent prior to the first tee. When these condi-

tions are not met, the computer displays a warning. It is

then up to the system designer to correct the piping vol-

ume to the first branch split. For example, when reading

Figure 4-1, in order to achieve 60% agent in pipe, a mini-

mum of 8.3% agent is required prior to the first tee. When

this condition is not met, the computer displays a warn-

ing. It is then up to the system designer to correct the

piping volume to the first branch split to meet this design

requirement (see Figure 4-2).

Limits: % of agent in pipe and % of agent

before first tee. (As computed by "FLOW",

do not use for manual computation.)

7.9%

8.3%

33.6%

0%

5%

10%

15%

20%

25%

30%

35%

0% 10% 20% 30% 40% 50% 60% 70% 80%

% OF AGENT IN PIPE

% OF AGENT BEFORE

FIRST TEE

Figure 4-1. Percent Agent Before First Tee as a

Function of Percent Agent in Pipe

4-2.3.2 TEE FLOW SPLITS

Flow splits at tee junctions are sensitive to gravity. Even

though turbulent flow exists, there is a tendency for the va-

por phase to migrate to the upper portion of the pipe leav-

ing a more dense medium at the bottom of the pipe. For

this reason, the limitations in Figure 4-2 must be observed.

4-2.3.2.1 Requirements for Tee Flow Splits

1. Bull head tees must have both outlets in the horizontal

plane. The inlet to a bull head tee may approach in a

horizontal, vertically up or vertically down direction.

2. Side tees must have the inlet and both outlets all in the

horizontal plane.

3. Elbows either before a tee, or after, which split to a

separate hazard must be located a minimum distance

of 15 pipe diameters (nominal) before the tee.

4. Tee splits going to separate hazards from a common

supply line must be spaced a minimum of 15 pipe di-

ameters (nominal) apart.

5. Pipe reducers must be the concentric reducer type.

6. Minimum flow out of a side tee branch is 10% of total

flow at the tee.

7. For flow splits less than 30%, the split shall be done

through a side tee with the smaller flow going through

the side tee member. The minimum flow through the

side tee member is 10%. The maximum flow through

the tee is 90%.

8. For flow splits equal to or greater than 30%, the split

shall be done through a bull head tee. The maximum

flow split through a bull head tee is 70%.

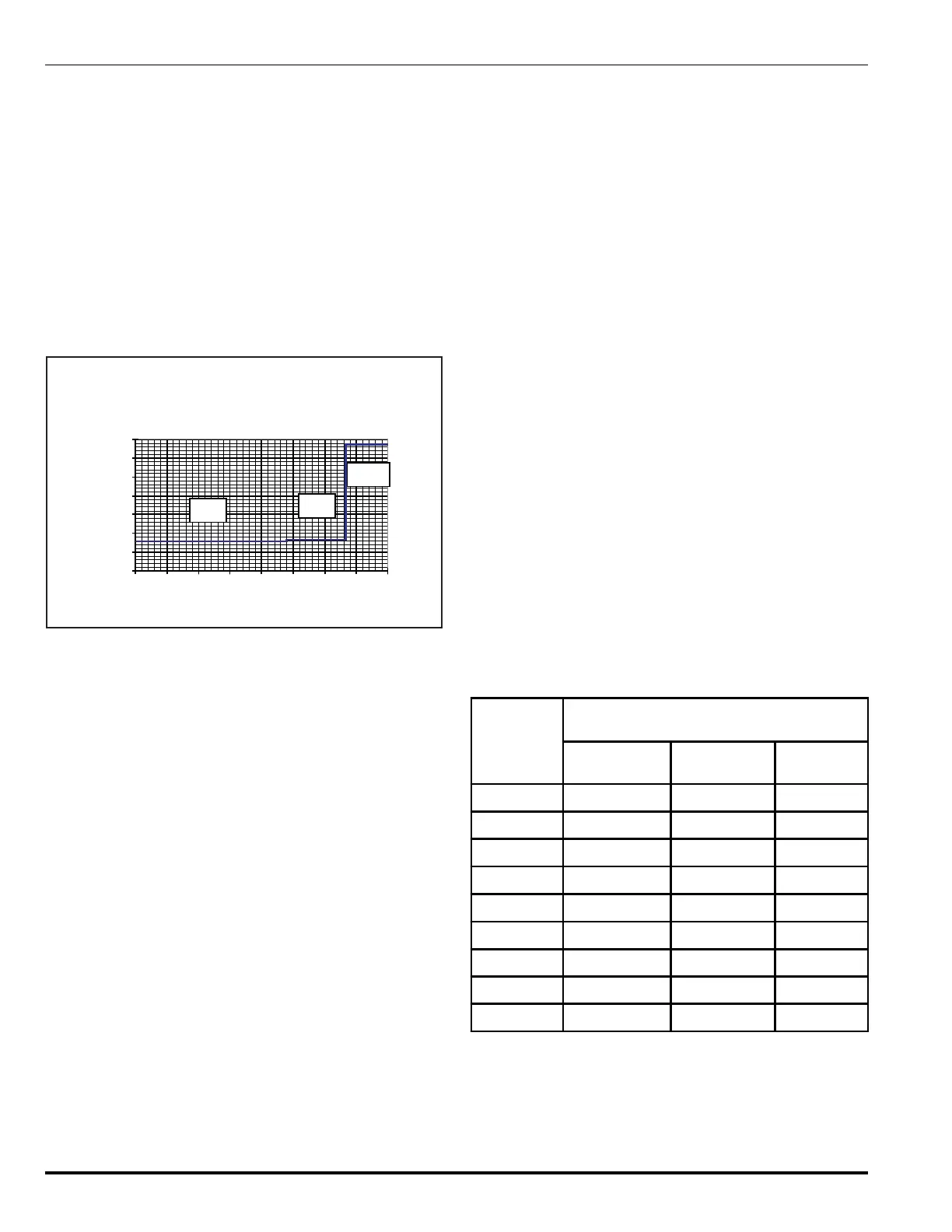

Table 4-5. 15 Pipe Diameters

Pipe Size

15 Pipe Diameters

feet

feet and

inches

meters

1/2"

0.63 7½ 0.192

3/4"

0.94 11¼ 0.287

1"

1.25 1'3" 0.381

1¼"

1.56 1'6¾" 0.475

1½"

1.88 1'10½" 0.573

2"

2.50 2'6" 0.762

2½"

3.13 3'1½" 0.954

3"

3.75 3'9" 1.143

4"

5.00 5' 1.524

Loading...

Loading...