4-8

90-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

4-2.3.3 DURATION OF DISCHARGE

Per NFPA 2001, the liquid agent discharge shall be completed

in a nominal 10 seconds or less. Discharge times shorter than

10 seconds are desirable to minimize production of break-

down products. Discharge times as short as six seconds

should be considered when circumstances permit.

4-2.3.4 NOZZLE SELECTION AND PLACEMENT

There are two basic Kidde nozzle configurations:

1. The 360° nozzle, which provides a full 360° discharge

pattern designed for placement in the center of

the hazard.

2. The 180° nozzle, which provides a 180° discharge pat-

tern designed for placement adjacent to a side wall of

the hazard.

Use ECS Series software as a tool to determine the selec-

tion of the required orifice area and nozzle.

Maximum orifice area to pipe area ratio:

The ratio between the nozzle orifice area for a 360 de-

gree nozzle at the given node and the pipe cross sec-

tional area for the pipe segment preceding that nozzle

is 0.72, or 72%,

The ratio between the nozzle orifice area for a 180 de-

gree nozzle at the given node and the pipe cross sec-

tional area for the pipe segment preceding that nozzle

is 0.66, or 66%.

Minimum orifice area to pipe area ratio:

The ratio between the nozzle orifice area for a 360 de-

gree nozzle at the given node and the pipe cross sec-

tional area for the pipe segment preceding that nozzle

is 0.27, or 27%.

The ratio between the nozzle orifice area for a 180 de-

gree nozzle at the given node and the pipe cross sec-

tional area for the pipe segment preceding that nozzle

is 0.27, or 27%.

Nozzles are available in nominal pipe sizes of 1/2", 3/4, 1",

1¼", 1½" and 2".

4-2.3.5 NOZZLE PLACEMENT

There are certain coverage and height limitations which

must be observed with each nozzle configuration to ensure

proper agent distribution.

44’

(13.3 m)

40’

(12 m)

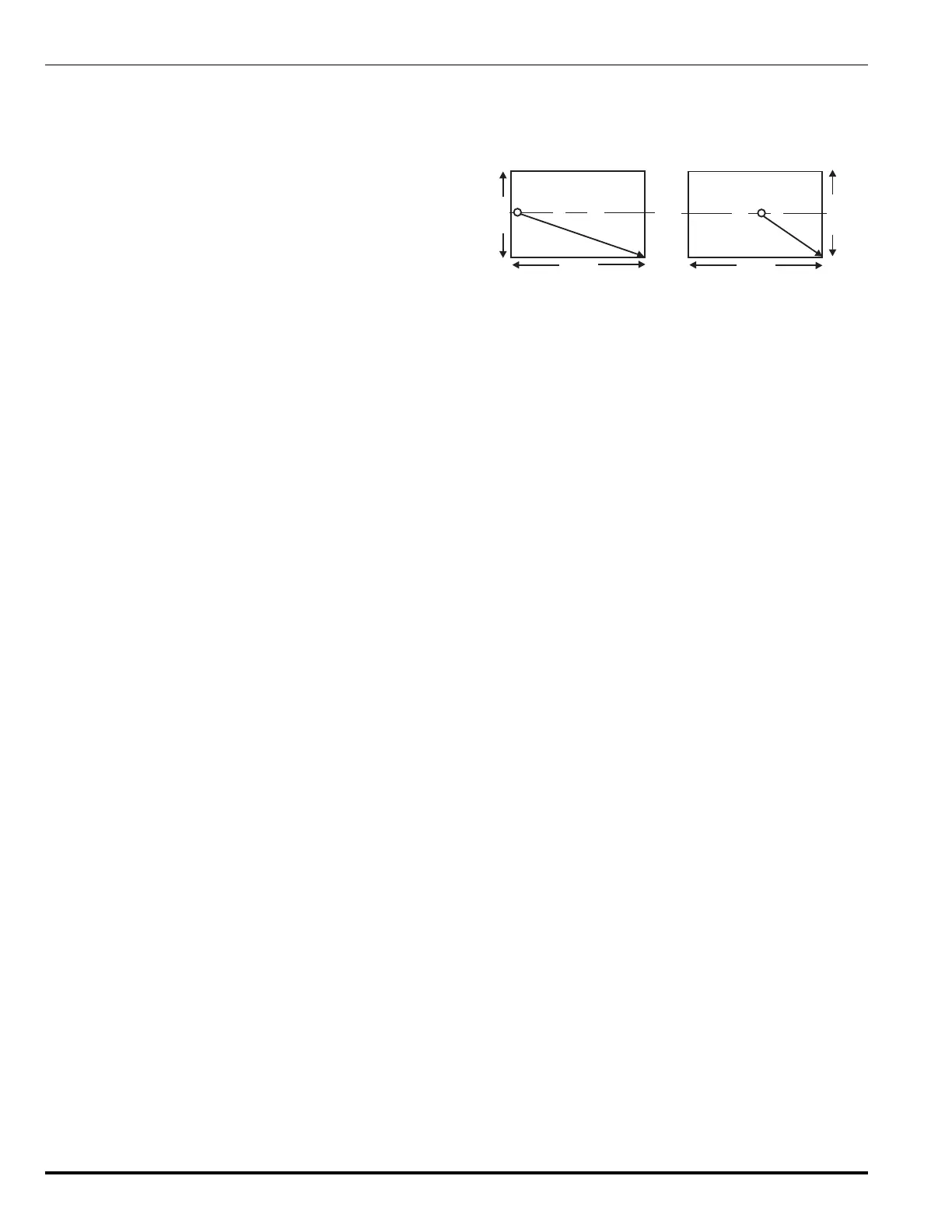

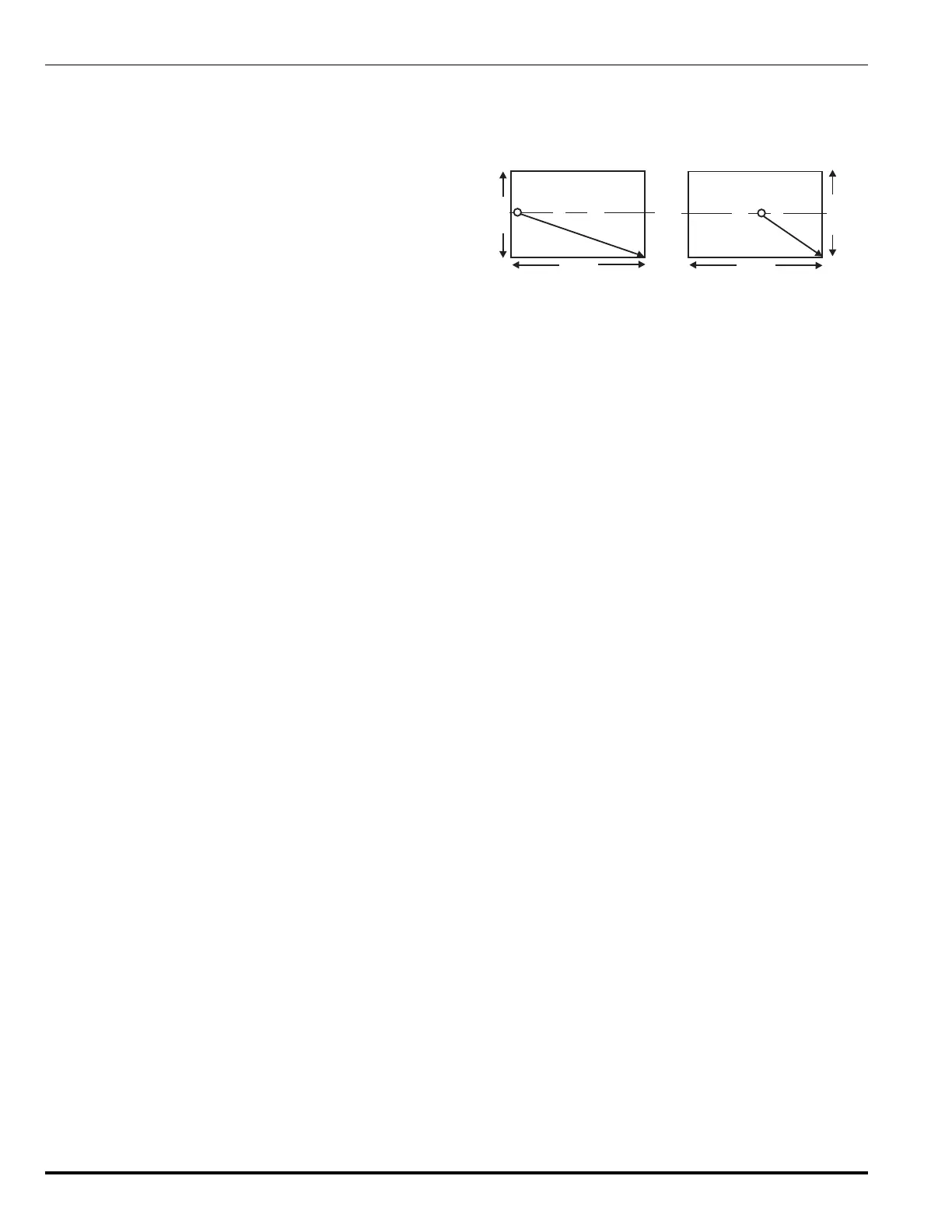

180° Nozzle 360° Nozzle

d = 29.7´

(9.06 m)

d = 48.3´

(14.73 m)

44’

(13.3 m)

40’

(12 m)

Figure 4-3. Nozzle Placement and Coverage

Orientation-Nozzles must be mounted perpendicu-

lar to the ceiling or subfloor surface and oriented with

the orifices radiating symmetrically outward from the

pipe network.

Ceiling Clearance-Nozzles must be installed so that

the orifices are located 6 +/- 2 inches (0.15 +/- 0.05 m)

below the ceiling.

Maximum Height-The maximum protected height for

a single row of nozzles is 16 feet (4.87 m). The 16 ft.

(4.87 m) coverage height includes the 6 +/- 2 inches

(0.15 +/- 0.05 m) below the ceiling.

Nozzles may be tiered to accommodate enclosures with

ceiling heights greater than 16 ft. (4.87 m).

Minimum Ceiling Height-The minimum ceiling

height for UL Listed/FM Approved systems is

1 ft. (0.3 m).

Systems designed for enclosures 6 to 12 inches

(0.15 m to 0.3 m) are acceptable, but not UL Listed

or FM Approved.

180° Nozzles-180° nozzles must be located 12 +/- 2

inches (0.3 +/- 0.05 m) from a wall, with the orifices

directed away from the wall. The nozzle shall be lo-

cated as close to the center of the wall as possible, but

at least 1/3 of the way along the wall.

180° nozzles have a maximum coverage area defined

as any rectangle that can be inscribed in a semicircle

of distance 48.3 ft. (14.73 m, diagonal of a rectangle

20' x 44'). Refer to Figure 4-3 for further information.

180° nozzles may be used in a back-to-back configu-

ration. The nozzles should be place 1 to 2 ft. (0.3 m to

0.6 m) apart.

360° Nozzles-360° nozzles must be located as close

to the center of the enclosure as possible. 360° nozzles

have a maximum coverage area defined as any rect-

angle that can be inscribed in a circle of radius 29.7 ft.

(9.06 m, diagonal of a rectangle 20' x 22'). Refer to

Figure 4-3 for further information.

Multiple Nozzles-Nozzles whose discharge patterns

will intersect must be placed at least 10 ft. (3.3 m) apart

to assure adequate agent distribution.

Loading...

Loading...