4-20

90-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

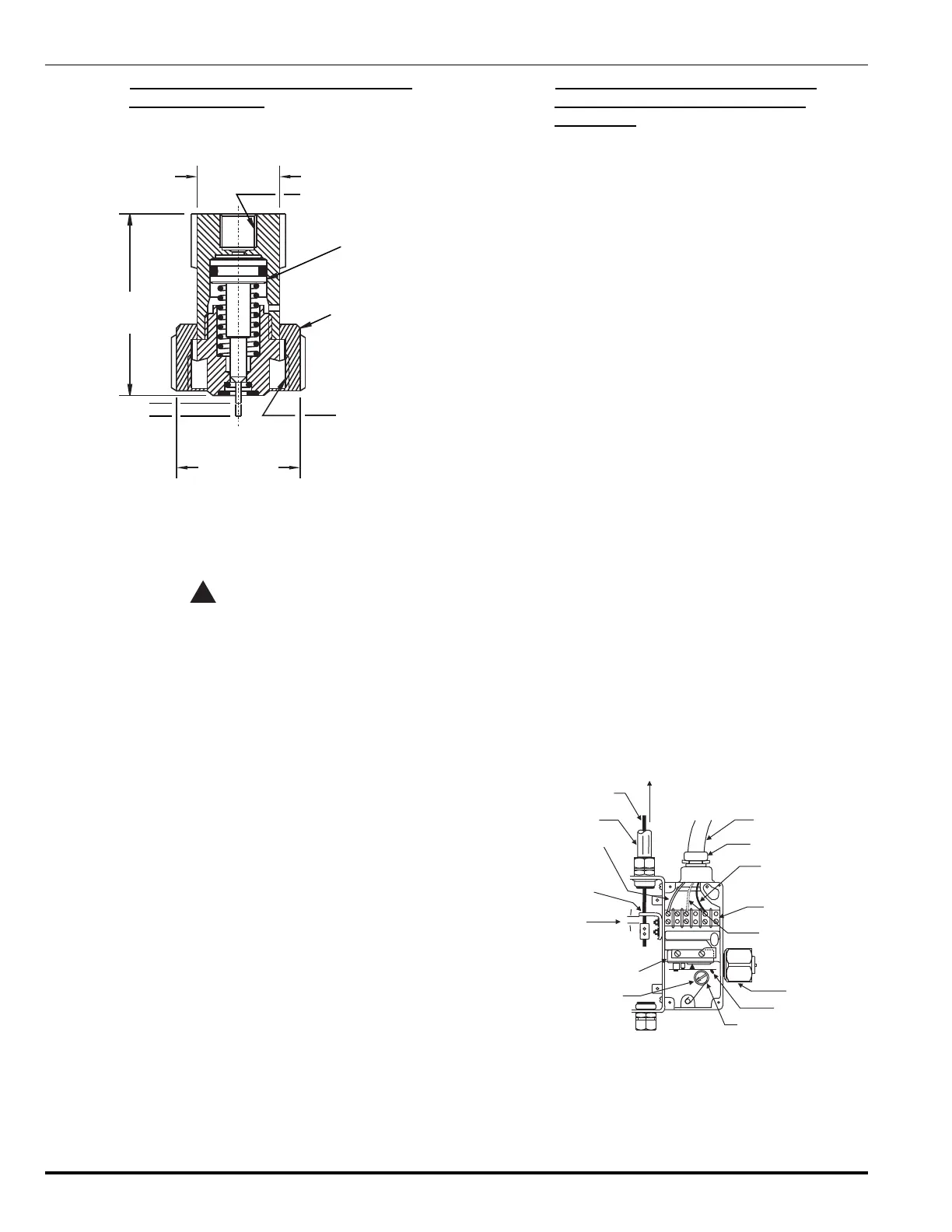

4-3.12 Installation of Pressure Operated Control

Heads, P/N 878737

1. Remove the protection cap from the cylinder actuation

port (see Figure 4-16).

1.250-18

UNEF-3B

SWIVEL NUT

PISTON

1/8"-27 NPT

PRESSURE INLET

SET

OPERATED

2.19"

(55.6 mm)

1.50" HEX

(38 mm)

1.00" HEX

(25.4 mm)

Figure 4-16. Pressure Operated Control Head

2. Install a pressure operated control head with flexible

actuation hose attached to the cylinder actuation port.

WARNING

!

Ensure that the pilot line is non-pressurized and

the actuating pins are in the retracted (SET)

position. Failure to follow this procedure will

cause the FM-200 cylinder to discharge

accidentally when the control head is installed

on the cylinder valve.

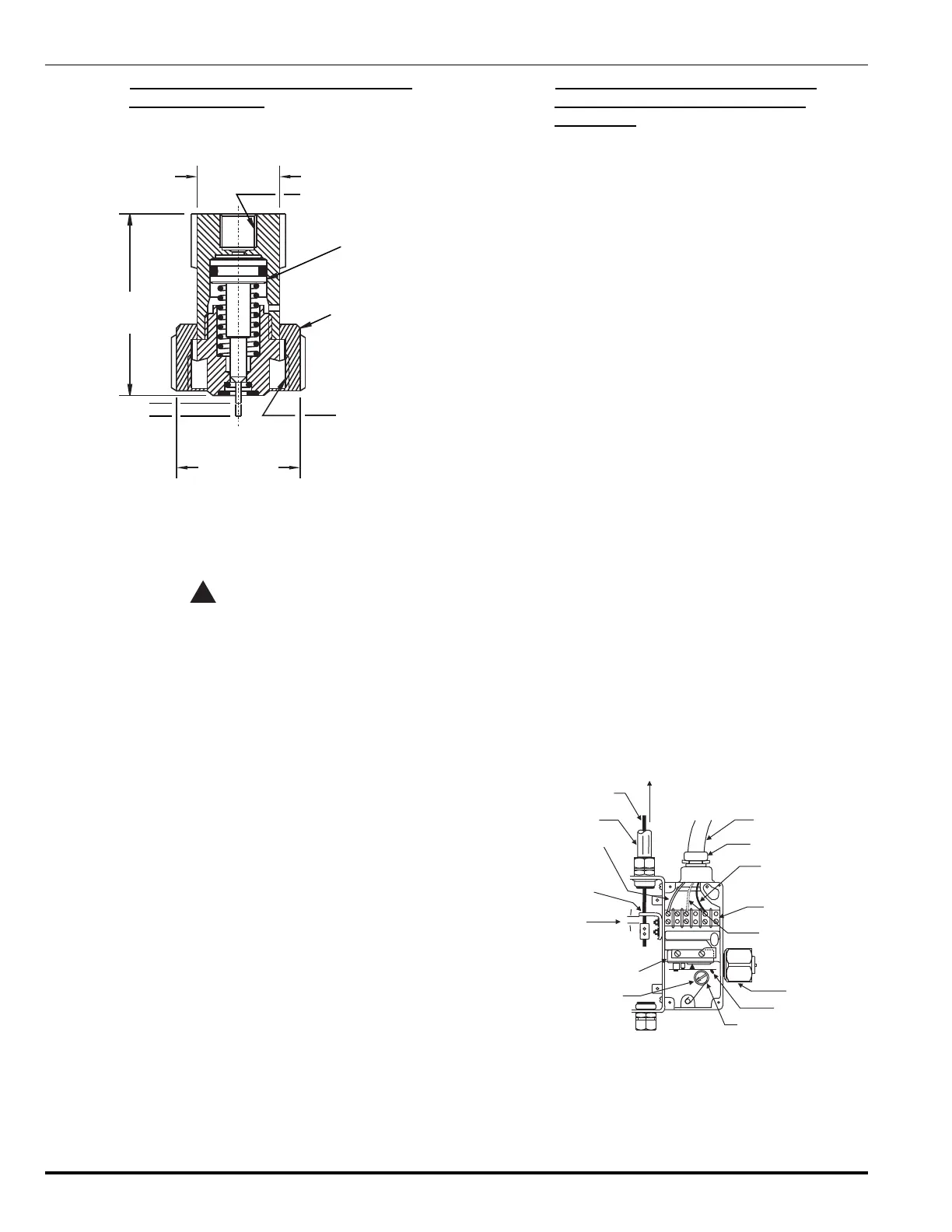

4-3.13 Installation of Electric/Cable Operated

Control Head, P/Ns 895630, 895627

and 895628

The following procedures must be performed before attach-

ing a control head to a cylinder valve (see Figure 4-17):

1. Remove the four screws holding the cable housing

cover on the control head. Remove the cover.

2. Position the control head in the approximately installed

position at the FM-200 cylinder valve control port but

do not assemble onto the actuation port of the FM-200

cylinder valve.

3. Check that the control head is in the SET position.

4. Assemble the pull cable conduit to the conduit connec-

tion on the control head.

5. Feed the cable into the control head through the hole

in the operating lever.

6. Feed the cable through the cable clamp. Pull the cable

taut, allowing approximately 1/4" to 1/2" clearance be-

tween the cable clamp and the operating lever. Tighten

the set screws in the cable clamp to secure the cable

to the clamp.

7. Cut off any excess cable.

8. Verify the manual remote cable operation to ensure con-

trol head actuates and all cable clamps are tight.

9. Pull the cable back to its normal set (non-operated)

position.

10. Reset the control head.

11. Replace the control head cover.

12. Examine the seal wire at the safety pull pin. Make sure

it is intact.

13. Make all electrical connections.

14. Assemble the control head to the cylinder valve actua-

tion port. Tighten the swivel nut securely.

1/2" E.M.T.

1/16” CABLE

PLUS OR HOT

CONNECTION

THREAD CABLE

THRU HOLE IN

OPERATING LEVER

POSITION CABLE

BLOCK APPROXIMATELY

AS SHOWN LEAVING

1/4” - 1/2” GAP

MICROSWITCH

INDICATOR AND

RESET STEM

FLEXIBLE CONDUIT

3/4” NPT BY FLEXIBLE

CONDUIT CONNECTOR

MINUS, NEUTRAL

OR GROUND

CONNECTION

TERMINAL STRIP

OPTIONAL CONNECTION

FOR MICROSWITCH

MICROSWITCH

LEVER

SWIVEL NUT

CAM

VIEW WITH COVER AND

NAMEPLATE REMOVED

DIRECTION

OF PULL

Figure 4-17. Electric/Cable Operated Control Head

Loading...

Loading...