4-22

90-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

4-3.18 Installation of Pressure Trip, P/N 874290

Install the pressure trip on the discharge manifold or piping

in the horizontal position as shown on the system draw-

ings. Connect the trip to the piping with 1/2-inch Schedule

40 pipe. The minimum operating pressure required is

75 PSIG (5.17 bar gauge). The maximum allowable load to

be attached to the retaining ring is 100 lb. (45.4 kg).

4-3.19 Installation of Manual Pull Station,

P/N 871403

1. Locate the remote pull boxes as shown on the system

installation drawings.

2. Connect the pull boxes to the control heads using 3/8-

inch, Schedule 40 pipe. Do not run more than one cable

in each pipe run.

3. Install a corner pulley at each change in pipe direction.

Do not bend the pipe. A dual-pull equalizer (P/N 840051)

should be installed where one pull box operates two

controls. A dual pull mechanism (P/N 840058) should

be installed where two pull boxes operate one control.

4. Beginning at the pull boxes, remove the covers of

the first corner pulley. Feed the cable through the

pulley into the 3/8-inch pipe. Connect one end of the

cable to the cable fastener in the pull box, allowing

the short end to project at least 1/2-inch. Seat the

cable in the groove by pulling on the long end. Screw

the fastener and cable into the handle. Route the

other end to the control heads, taking up as much

slack as possible. Attach the end of the cable to the

fastener in the control head.

5. Reattach the corner pulley covers.

6. Check that control head is in SET position. Install the

control head to the FM-200 cylinder valve.

4-3.20 Installation of Discharge Indicator,

P/N 875553

The discharge indicator must be installed on the discharge

manifold, either in a vertical or horizontal position. The indi-

cator has a 3/4-inch NPT male connection. Make certain

the indicator stem is in the normal position.

4-3.21 Installation of Supervisory Pressure Switch,

P/Ns 06-118262-001 and 06-118263-001

Installation of the supervisory pressure switch can be ac-

complished safely on a pressurized cylinder.

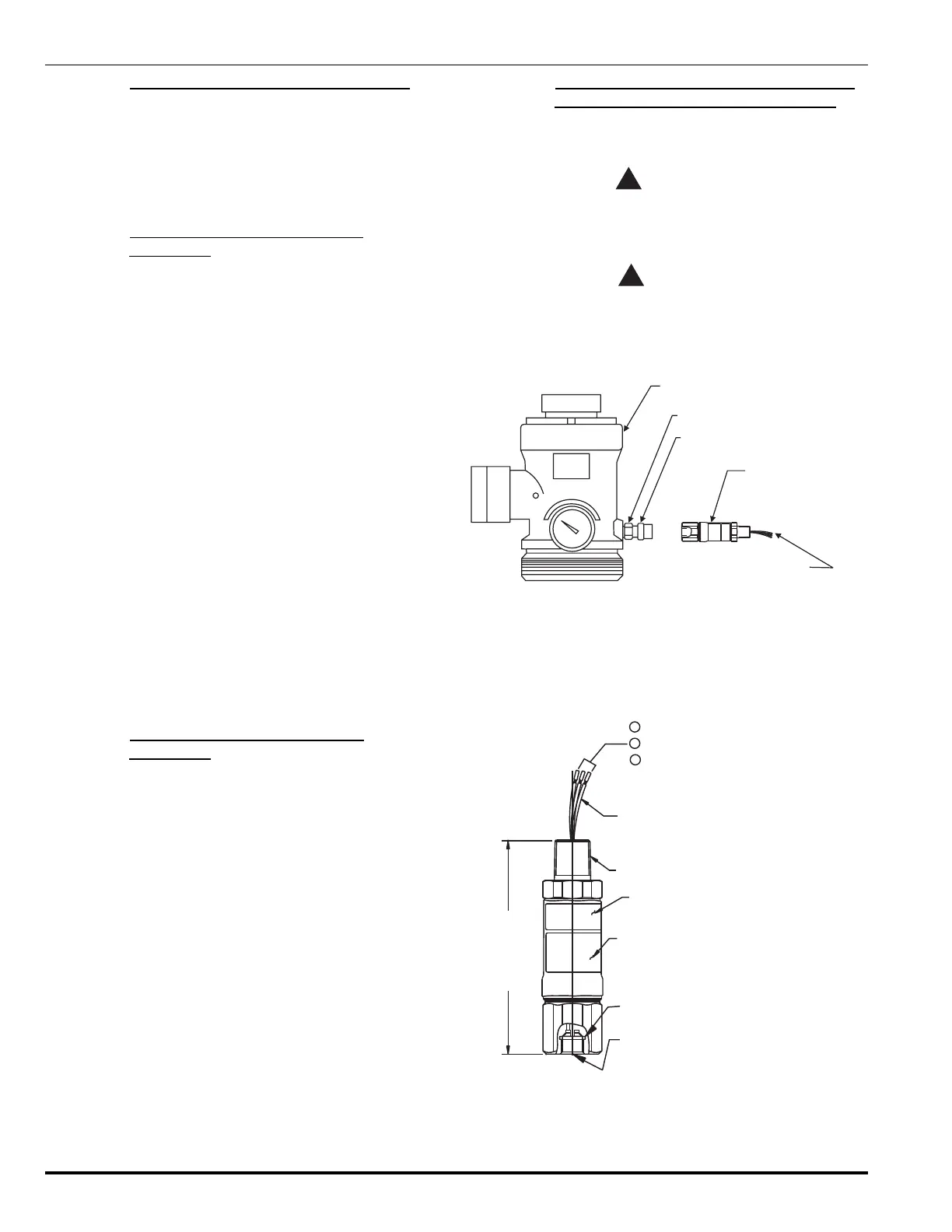

WARNING

!

Before installing the pressure switch,

de-energize all electrical components to

prevent injury.

CAUTION

!

When attaching or removing the supervisory

pressure switch from the cylinder valve, attach

a wrench to the fitting and hold securely while

tightening or loosening the pressure switch.

VALVE

WRENCH FLATS

SUPERVISORY PRESSURE

SWITCH FITTING

PRESSURE SWITCH

ELECTRICAL CABLE

FOR SWITCH CONNECTION

Figure 4-18. Installation of Supervisory

Pressure Switch (Up to 2½" Valve)

Note: The control panel must be UL Listed and/or

FM Approved for releasing device service and com-

patible with Kidde FM-200 equipment.

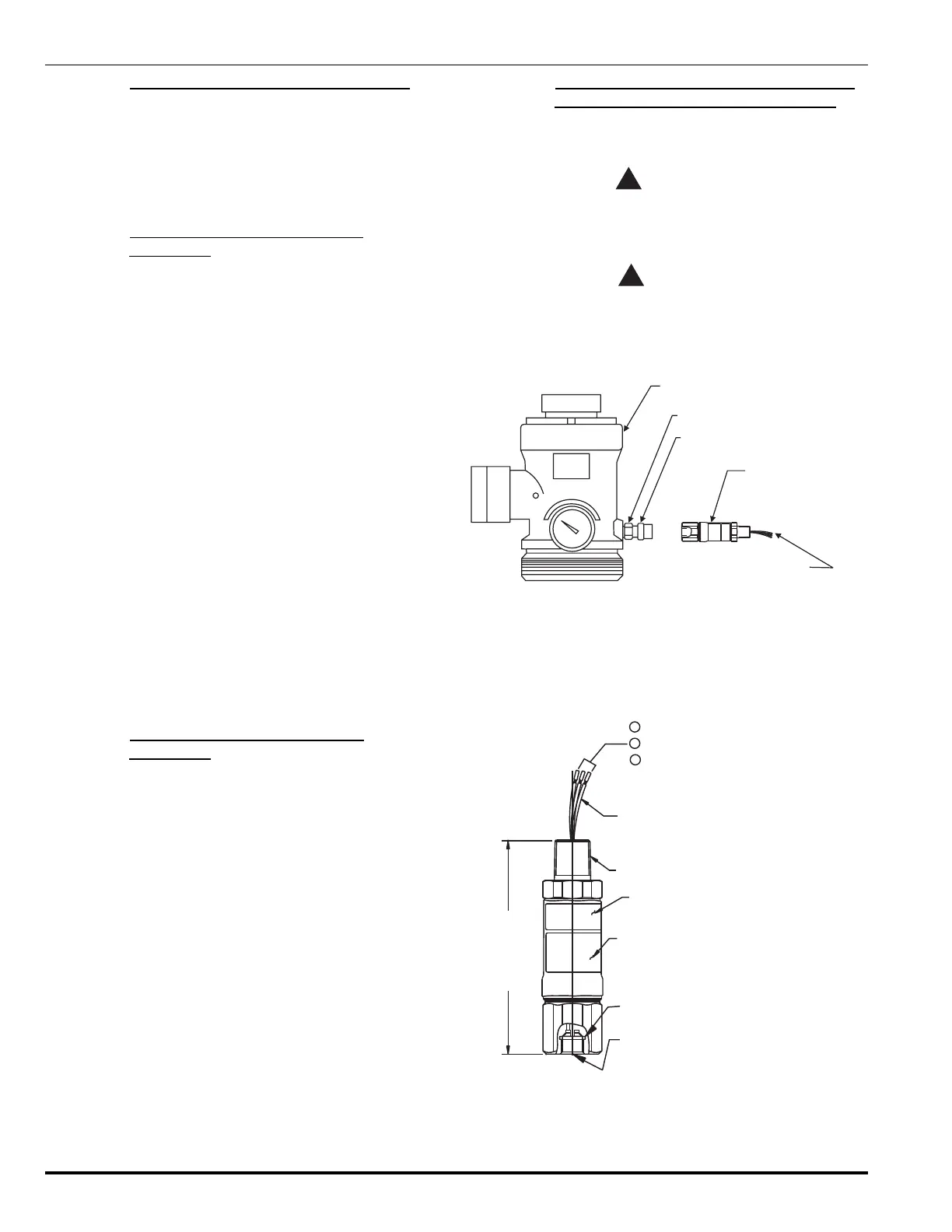

NAMEPLATE LABEL

0.500 -14 NPT

FACTORY SEALED

LEADWIRES 36" LONG ± 1”

CAUTION LABEL

O-RING

0.250" SAE 45° FLARE

(CONNECTION FOR

06-118262-001

SHOWN)

3

2

1

BLUE: N.O. (N.C. UNDER PRESSURE)

BLACK: N.C. (N.O. UNDER PRESSURE)

VIOLET: COM.

4.125”

(10.48 cm)

Figure 4-19. Supervisory Pressure Switch

Electrical Connections

Loading...

Loading...