4-23

September 2004 90-FM200M-000

FM-200

®

ECS Series Engineered Fire Suppression Systems

P

213

• 5A 24 Vdc (Resistive)

• 5A 240 Vac (Resistive)

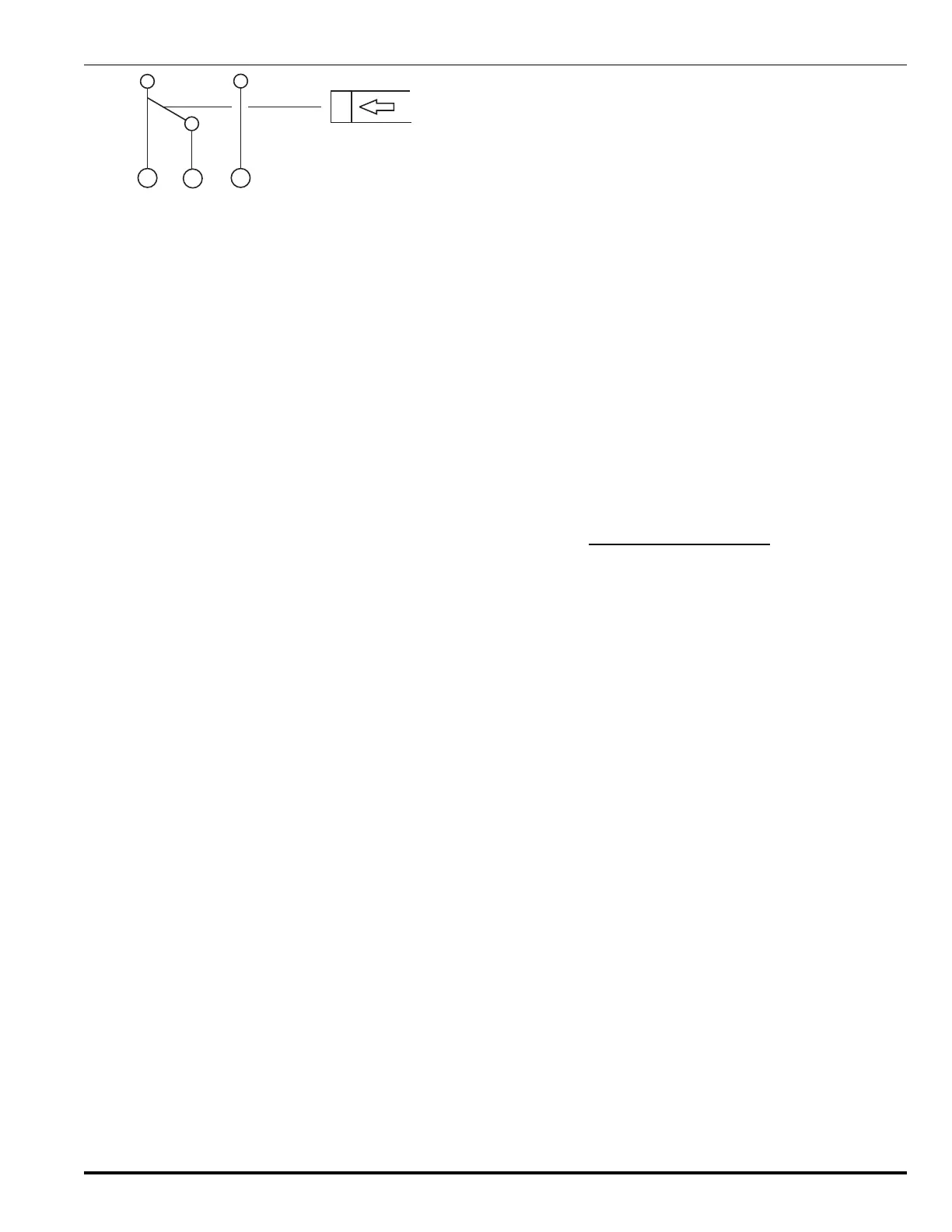

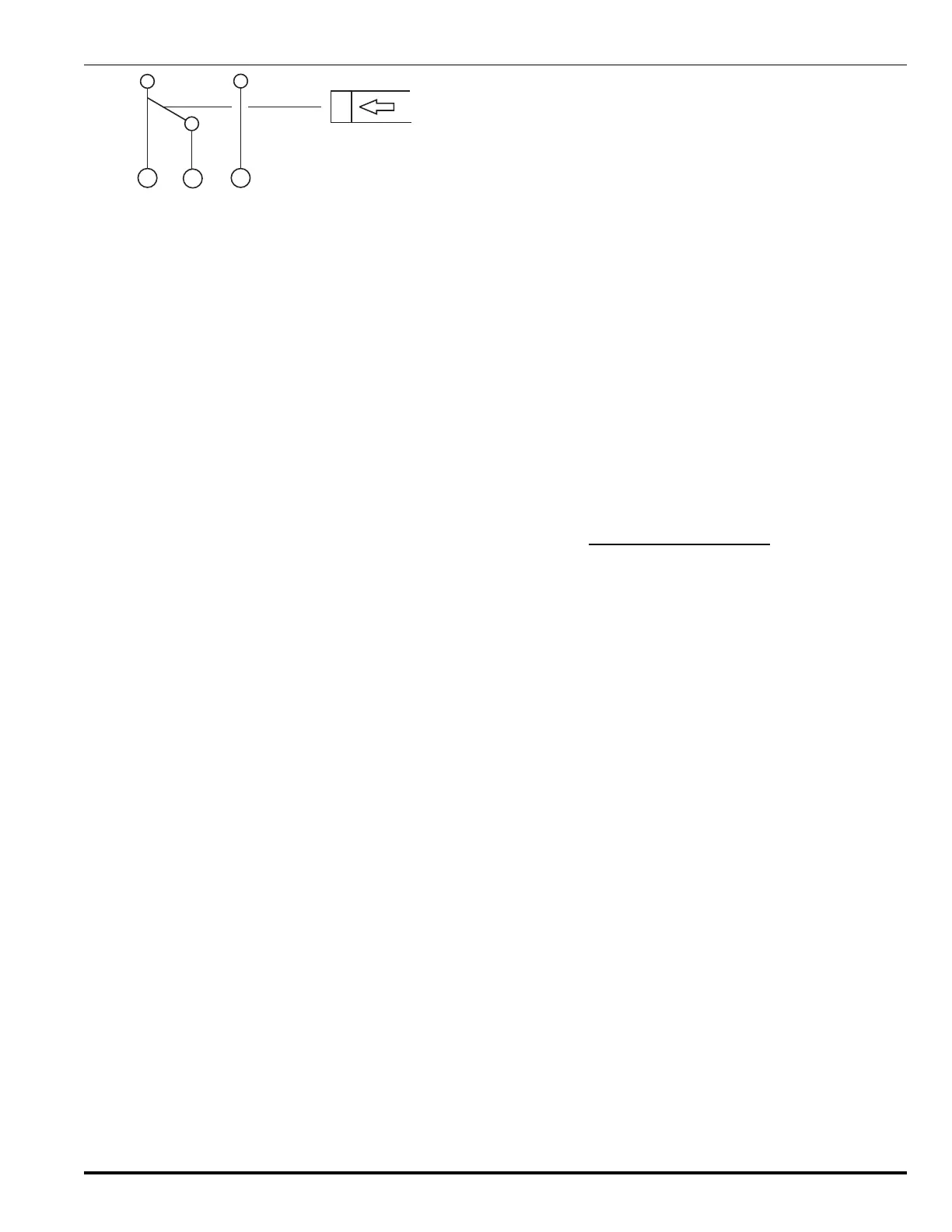

Figure 4-20. Supervisory Pressure Switch

Connection Diagram and Electrical Rating

Note: When cylinder supervisory pressure switch

(P/N 06-11826X-001) is connected to a supervised

control panel circuit, and the switch is wired NC

under pressure, it is not possible to distinguish

between a wiring fault and a loss of container pres-

sure. This configuration should only be used if ac-

cepted by the Authority Having Jurisdiction.

4-3.21.1 INSTALLATION OF PRESSURE SWITCH

06-118262-001

Install the pressure switch as follows:

Note: Do not use with 3" valves.

1. Check that the sealing surface of the flare connection

of the supervisory switch is not scratched, dented,

scored, etc.

2. Remove the end cap from the pressure switch port of

the valve. This is a flare fitting and does not require

tape dope or any type of sealant.

3. Install the pressure switch onto the pressure port of

the valve. Be sure to secure the pressure port with a

wrench so that you are not turning the port fitting fur-

ther into the valve. Tighten the switch hand-tight and

then tighten 1/4-turn further using a wrench.

4. Important: Leak test the pressure switch connection

with an FM-200 leak detector or a bubbling solution. If

the connection leaks, the switch may be tightened fur-

ther until the leak is eliminated, again, be sure to have

a counter wrench on the switch port.

4-3.21.2 INSTALLATION OF PRESSURE SWITCH

06-118263-001

Install the pressure switch as follows:

Note: For 3" valves only.

1. Hold the pressure switch fitting on the valve with a

wrench and remove the 1/8-inch plug with a second

wrench. Ensure that the fitting does not rotate in the

valve body. The fitting contains a check valve that will

prevent the escape of the cylinder contents.

2. Before fitting the switch, apply Permacel

®

No. 412D

Te f lo n

®

tape to the male threads of the pressure switch.

3. Install the pressure switch into the port of the valve. Be

sure to secure the pressure port fitting with a wrench.

Tighten the switch hand-tight and then tighten 1¼-turns

further using a wrench.

4. Important: Leak test the pressure switch connection

with an FM-200 leak detector or a bubbling solution. If

the connection leaks, the switch may be tightened fur-

ther a 1/4-inch turn at a time until the leak is eliminated,

again, be sure to have a counter wrench on the switch

port. Do not exceed two turns from hand-tight. Refer to

ANSI B1.20.3 for NPT thread engagement details.

4-3.22 Post-Installation Checkout

After an FM-200 system installation has been completed,

perform the following inspections and tests.

1. Verify that the cylinders of correct weight and pressure

are installed in accordance with installation drawings.

2. Verify that the cylinder brackets and straps are properly

installed and all fittings are tight.

3. The piping distribution system must be inspected for

compliance with the system drawings, NFPA 2001, de-

sign limitations within this manual and the computer-

ized hydraulic calculations associated with each

independent piping and nozzle configuration.

4. Check that the discharge manifold, discharge piping and

actuation piping are securely hung. Ensure all fittings

are tight and securely fastened to prevent agent leak-

age and hazardous movement during discharge. The

means of pipe size reduction and installation position of

the tees must be checked for conformance to the de-

sign requirements.

5. The piping distribution system must be cleaned, blown

free of foreign material and inspected internally to en-

sure that oil or particulate matter will not soil the hazard

area or reduce the nozzle orifice area and affect agent

distribution.

6. System piping should be pressure tested in accordance

with the requirements of NFPA 2001.

Loading...

Loading...