6-1090-FM200M-000 September 2004

FM-200

®

ECS Series Engineered Fire Suppression Systems

6-4.3 Nitrogen Cylinder Recharge

Nitrogen cylinders must be recharged when the cylinder

pressure gauge indicates pressure is below normal (1800

PSIG at 70°F [124 bar gauge at 21°C] or as adjusted for

temperature) or immediately after discharge. Nitrogen used

for charging must comply with Federal Specification

BB-N-411C, Grade A, Type 1. Copies of this specification

may be obtained from: Global Engineering Documents,

2625 S. Hickory St., Santa Ana, CA 92707.

WARNING

!

Before recharging, the cylinder must be firmly

secured by chains, clamps or other devices to

an immovable object such as a wall, structural

I-beam or permanently mounted holding rack.

Recharge the nitrogen cylinders as follows:

1. Remove the protection cap from the cylinder valve ac-

tuation port.

2. Install the nitrogen cylinder recharge adapter

(P/N 933537) to the cylinder valve actuation port and

plug valve outlet port with 1/8" NPT pipe plug.

3. Connect the nitrogen recharging supply hose to the

adapter. Tighten securely.

4. Open the nitrogen recharging control valve slowly until

full nitrogen flow is obtained.

5. Monitor the recharging supply pressure gauge. Close

the charging control valve when the gauge indicates

the proper cylinder pressure (1800 PSIG at 70°F

[124 bar gauge at 21°C]).

6. Allow the cylinder to cool to ambient temperature and

recheck the nitrogen cylinder pressure.

7. Open the valve and add additional nitrogen as neces-

sary to obtain a full cylinder charge at ambient tem-

perature (1800 PSIG at 70°F [124 bar gauge at 21°C]).

Refer to Figure 6-5.

8. Close the valve and remove the supply hose and charg-

ing adapter from the nitrogen cylinder.

9. Using a soap solution, thoroughly check the nitrogen

cylinder valve for leakage. Bubbles in the soap solu-

tion indicate leakage and shall be cause for rejection

of the cylinder.

10. At the completion of the leak test, thoroughly clean and

dry the cylinder valve.

11. Ensure the cylinder valve control head port is clean

and dry.

12. Immediately install the protective cap to the actuation

port of the cylinder valve.

13. Install the charged cylinder as described below.

6-4.4 Nitrogen Cylinder Installation

1. Install the nitrogen cylinder in position in the mount-

ing bracket.

2. Tighten sufficiently to hold cylinder in place while al-

lowing cylinder enough free play to be manually rotated.

3. Turn the cylinder until the cylinder valve discharge out-

let is in the desired position.

CAUTION

!

The nitrogen cylinder must be positioned so

that the control head, when installed, is readily

accessible and cannot be obstructed during

manual operation.

4. Securely tighten the mounting bracket clamps

and hardware.

5. Remove the pipe plug, reconnect the adapter

(P/N 6992-0501) and flexible actuation hose or tubing

to the cylinder valve outlet port.

6. Remove the protective cap from the cylinder valve

actuation port.

WARNING

!

Ensure the control head is in the SET position

(that is, the actuating pin is in the fully retracted

or SET position). Failure to do so will cause

the nitrogen cylinder to discharge when the

control head is installed.

7. Install the control head to the cylinder valve and

tighten securely.

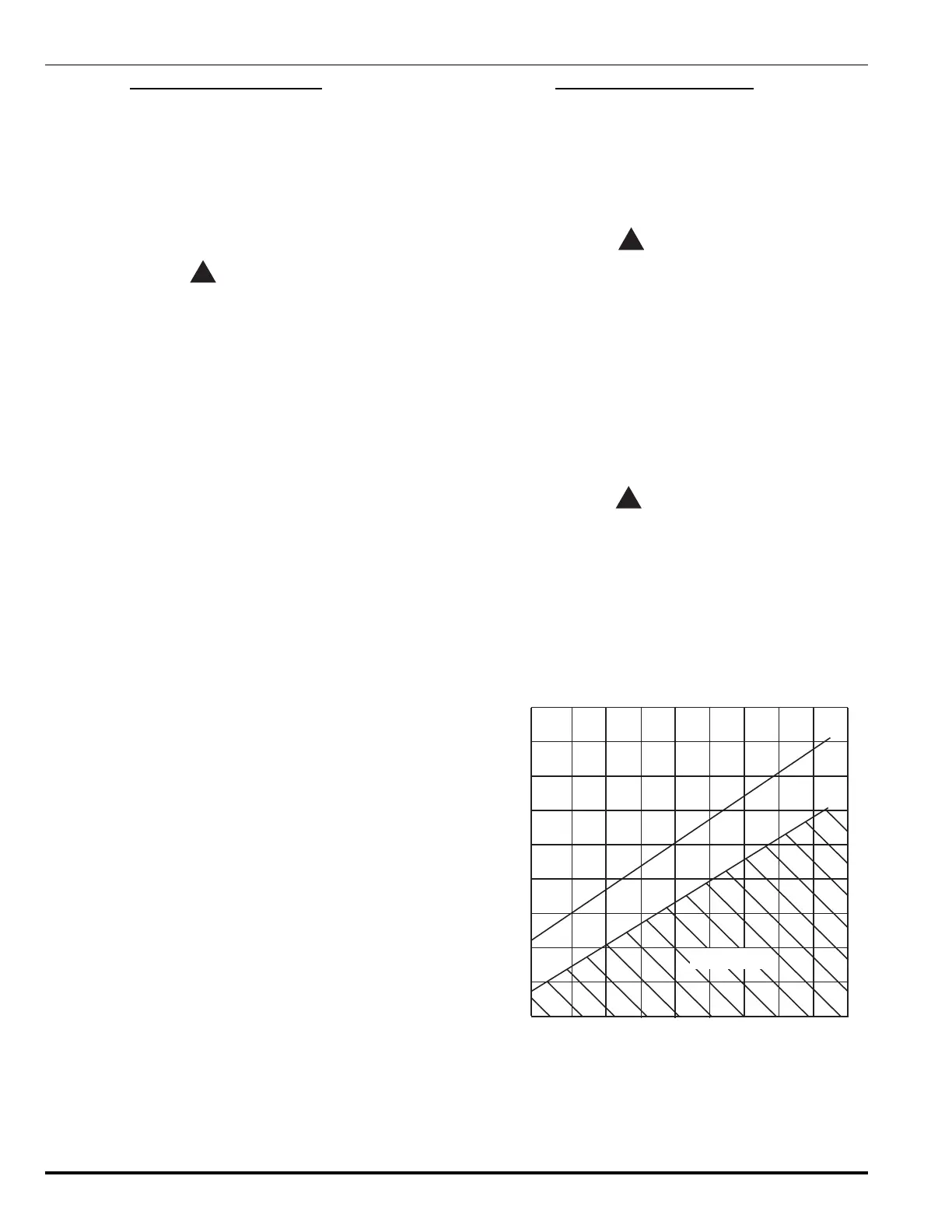

TEMPERATURE °F

N PRESSURE - TEMPERATURE CHART

2

PRESSURE PSIG

-40° 40° 60°-20° -20°0° 80° 100° 120° 140°

1200

1300

1400

1500

1600

1700

1800

1900

2000

2100

RECHARGE

NOMINAL PRESSURE

MINIMUM ALLOWABLE PRESSURE

Figure 6-7. Nitrogen Temperature vs. Pressure Data

Loading...

Loading...