4 / 6 P/N 3101069-EN • REV 005 • ISS 19OCT20

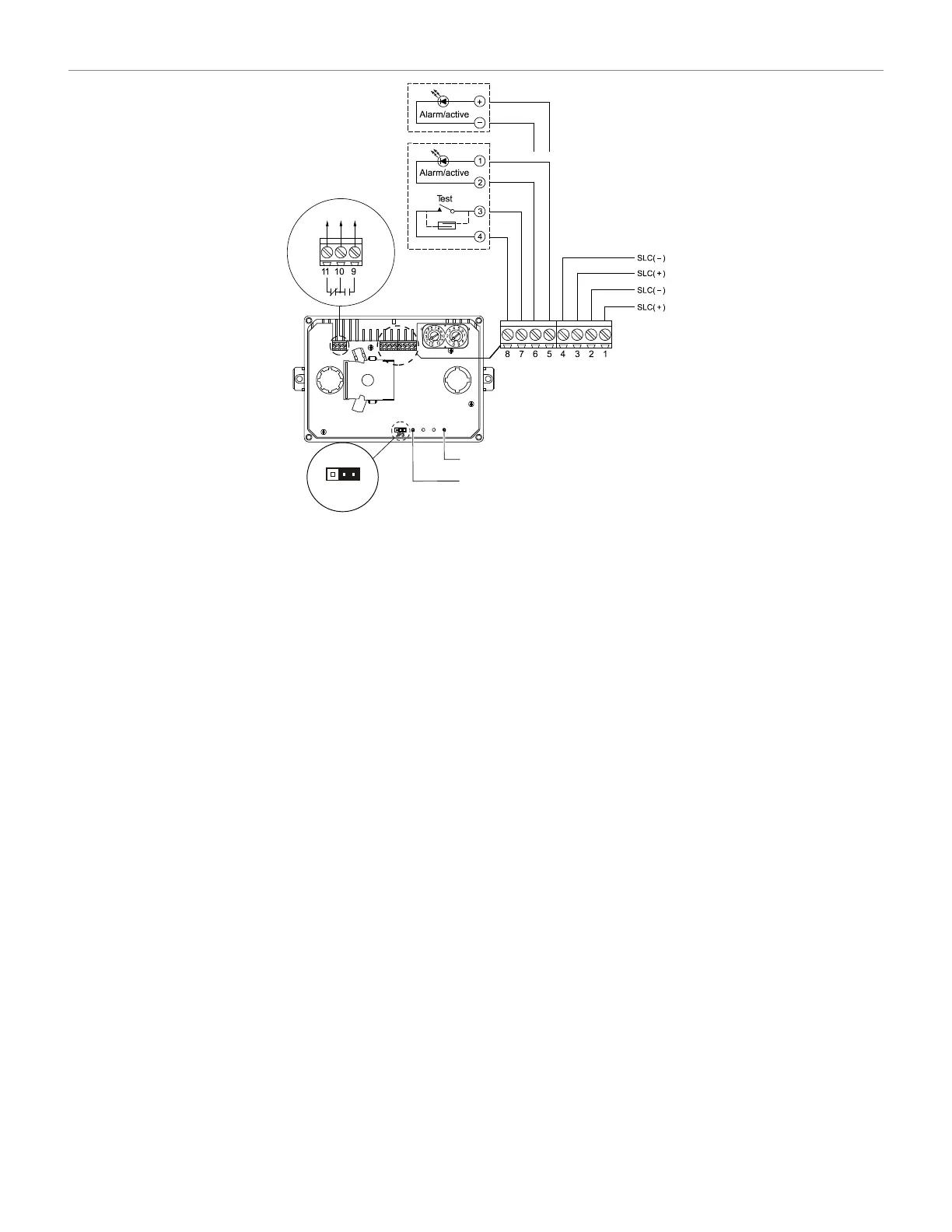

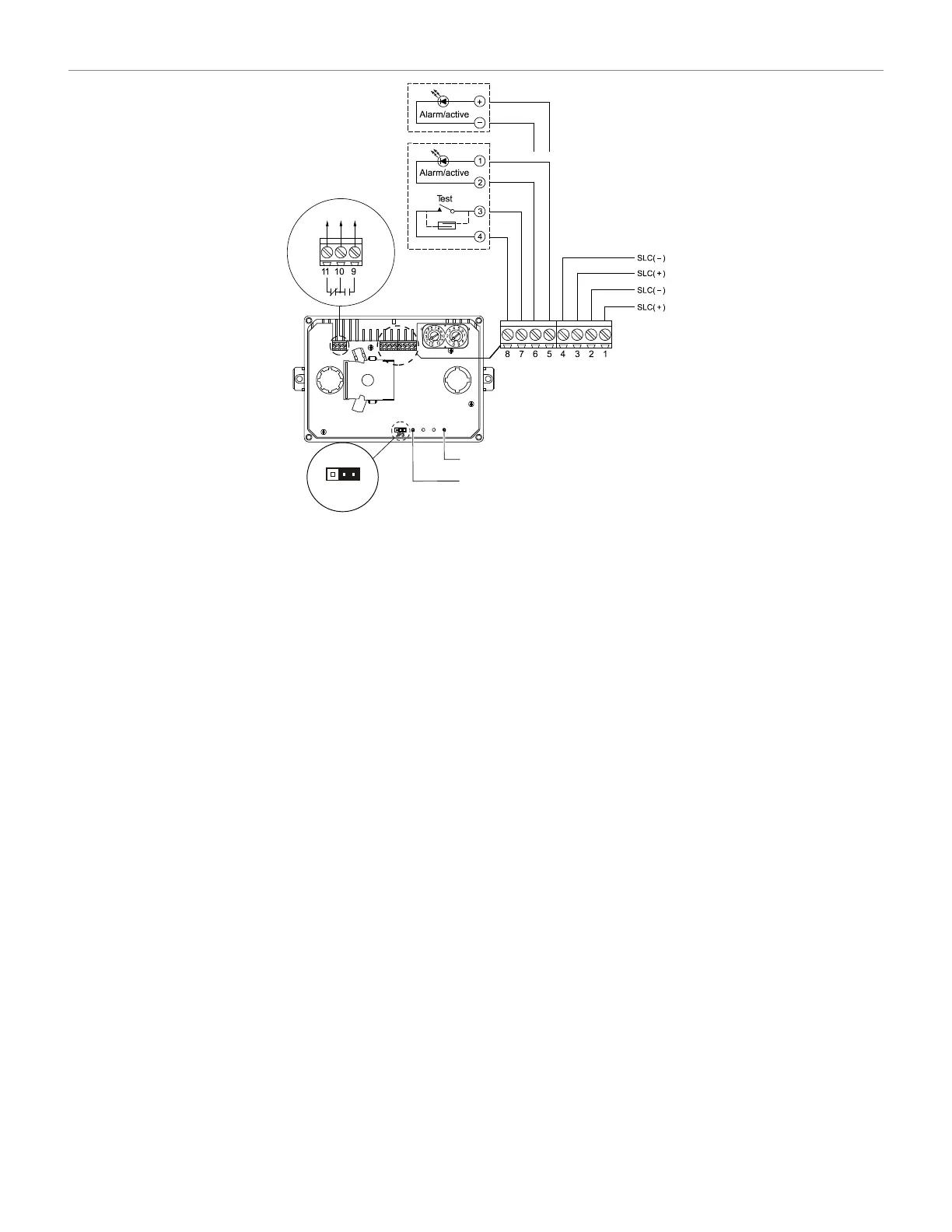

Figure 6: Duct detector wiring

(1) Auxiliary equipment. Power-limited unless connected to a

nonpower-limited source. If the source is nonpower-limited,

eliminate the power-limited mark and maintain a minimum of

0.25 in. (6.4 mm) space from power-limited wiring. For other

mounting methods, see enclosure and bracket installation sheets

to maintain separation of power-limited and nonpower-limited

wiring. The wire size must be capable of handling fault current from

the nonpower-limited source.

— or —

Use type FPL, FPLR, FPLP, or permitted substitute cables,

ensuring that the power-

limited cable conductors extending beyond

the jacket are separated by a minimum of 0.25 in. (6.4 mm) space

or by a nonconductive sleeve or nonconductive barrier from all

other conductors. The wire size must be capable of handling fault

current from the nonpower-limited source. Refer to NFPA 70 for

more details.

(2) Remote alarm/active indicator. See “Specifications” on page 5 for a

list of available model numbers.

Connect only one remote test station or LED indicator to the

detector. Wiring is unsupervised. Maximum wire resistance is 10

per wire.

Remote test station. See “Specifications” on page 5 for a list of

available model numbers.

Power indicator.

Alarm Indicator.

JP3 (shown in the factory default position, for supervisory mode).

Alarm position.

Supervisory position.

Testing

Verifying the air pressure differential

In order to verify air pressure differential, air must be moving through

the HVAC system.

To verify the air pressure differential:

1. Connect a suitable air pressure differential meter to the sampling

tube and exhaust tube openings as shown in Figure 7.

2. Verify that the air pressure differential reading falls within the

specified operating range of the detector. See “Specifications” on

page 5.

3. If the air pressure differential measured does not fall within the

specified operating range of the detector, make sure the sampling

tube air holes are not obstructed and are facing the HVAC system

airflow.

(1)

(5)

(6)

(2) (3)

(3) (4)

JP3

(7)

(8) (9)

Loading...

Loading...