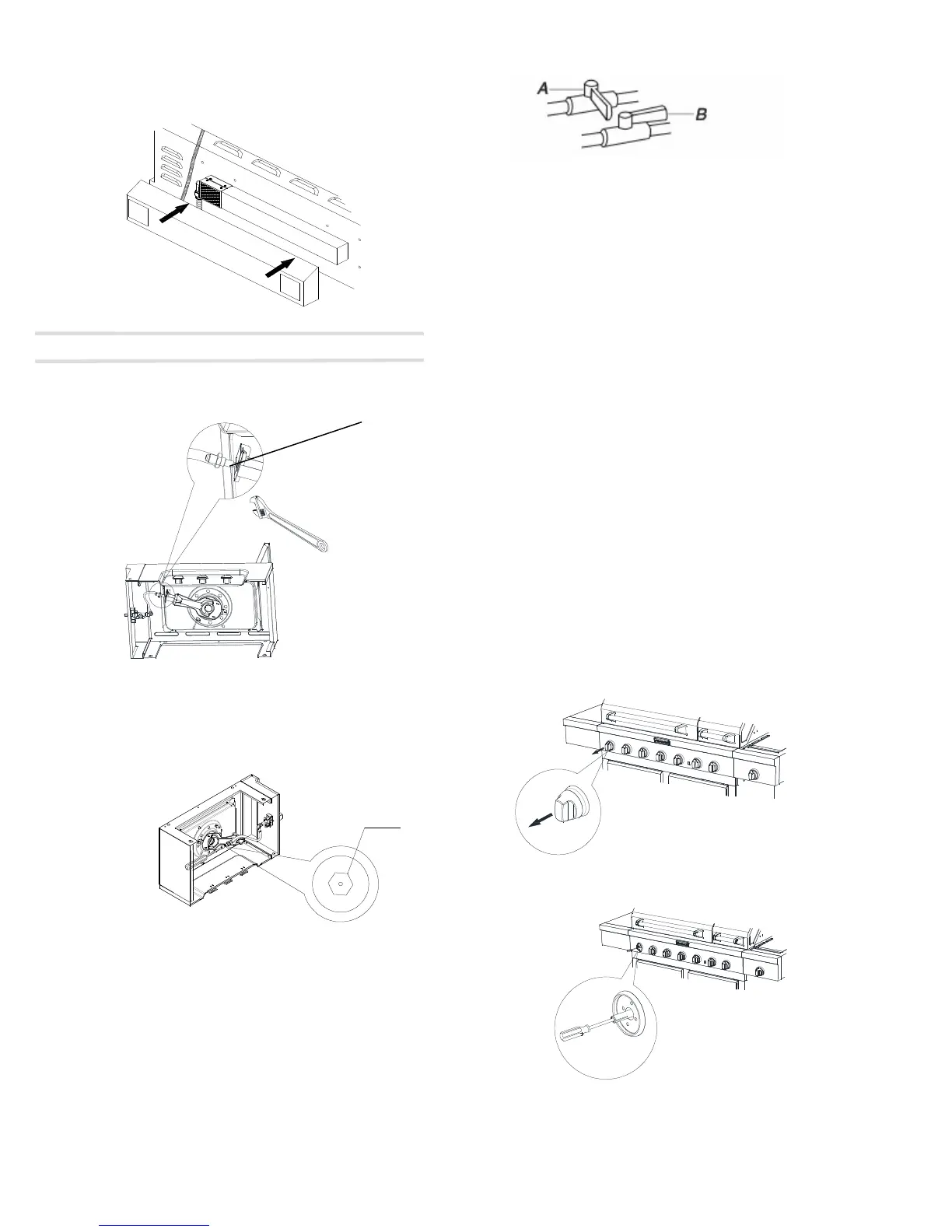

Change the Side burner Orifices

1. Use a wrench to remove the side burner orifice brass

connector with flex line end to side burner tube.

A

5. Test all connections using an approved noncorrosive leak-

detection solution. Bubbles will show a leak. Correct any

leak found

A. Closed valve

B. Open valve

2. In the last page of the Use and Care Guide, write;

“Converted to Natural Gas.” Also record the conversion

date and the technician/company that performed the

conversion.

Note: Place LP gas parts in plastic parts bag for future use and

keep with pack containing literature.

1. The appliance nameplate is located inside the grill

cabinet on the left –hand cabinet side. With a

permanent marker, check the box next to “Natural

gas” and mark through “LP-Propane.”

Record Conversion

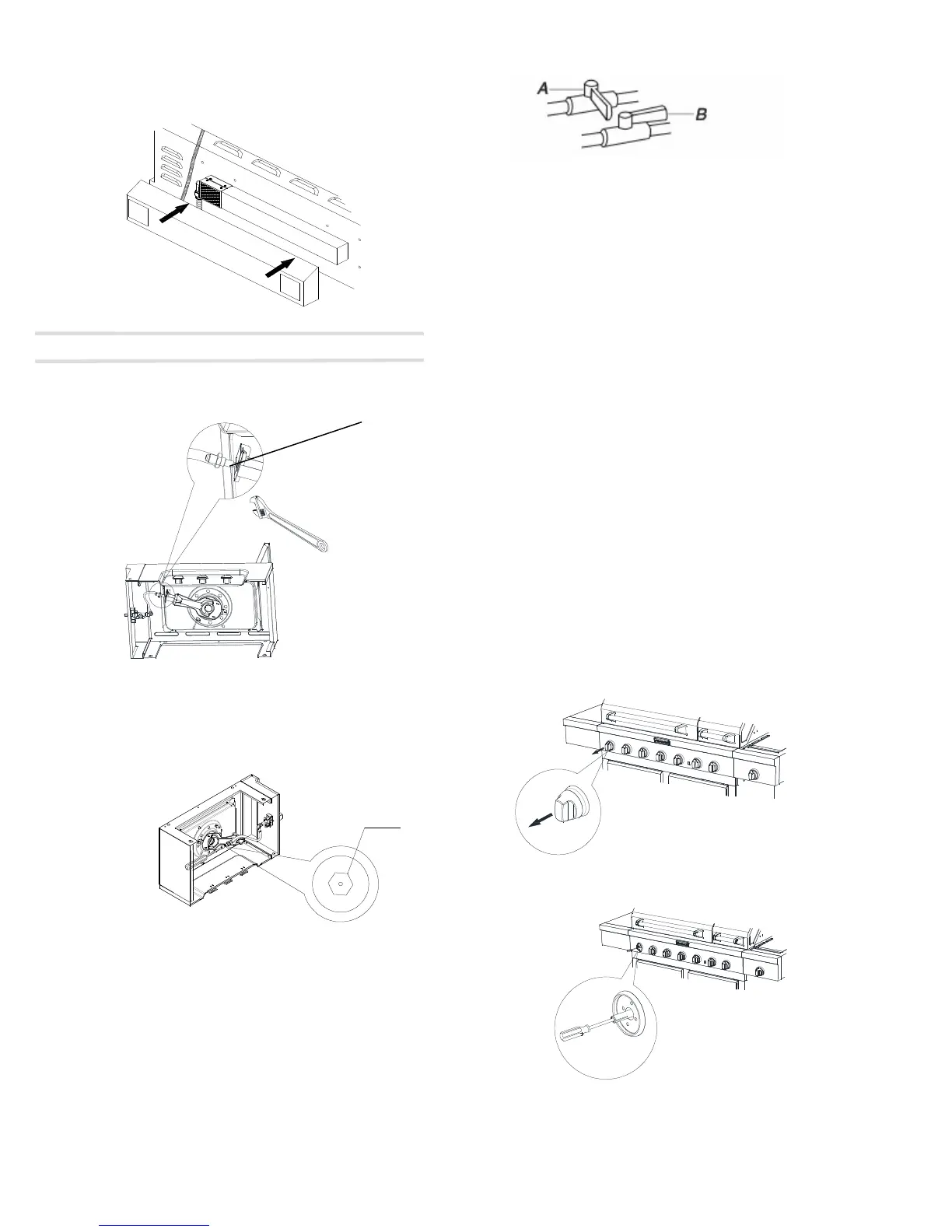

Adjust High Flame Setting Screw

When converting from LP to Natural gas, you will need to

6. Re-Attach the rear baffle and lock all removed screws.

A. Side burner flex end

2. Use 6 mm socket wrench or 6 mm nut driver to remove the

orifice. Replace with the Natural gas orifice.

A. Orifice

A

IMPORTANT:

Check that the orifice is properly installed inside of the valve.

3. Reinstall side burner, tighten the side burner orifice brass

connector and side burner tube by using a wrench.

4. Open the manual shutoff valve in the gas supply. Then

valve is open when the handle is parallel to the gas pipe.

2. Use a small precision flat-blade screwdriver to turn the

high flame set screw counter-clockwise, approximately 90

degrees.

When converting from LP to Natural gas, you will ne

ed to

adjust the high flame setting screw for ideal burner flame

height.

1. Remove each control knob for the main burners and side

burner

3. Check that burner operates at the new high flame setting. It

may be necessary to adjust the screw setting slightly more

to get the ideal burner flame height.

22

Loading...

Loading...