F. Hydraulic oils / filters

The elevator is supplied with hydraulic oil (TITAN FUCH H32 oil). This oil is made for use in

"temperate climates” and provides good service at regular temperatures. H46 oil is also suitable

but its compulsory to use an HV type oil

The oil filter must be changed after the first 30 days of use and then after 1 year or 500h of use

(whichever comes first) depending on how often the elevators is used.

Pump cavitation denoted by noisy operation is due to a clogged filter, a low oil level or weather

conditions there are too cold for the type of oil being used.

To change the oil filter, unscrew the filter block and replace it with a new one, carefully and slightly

oiling the gasket.

G. Greasing

Slew ring

The slew ring is supplied correctly lubricated.

- Greece to be used: VANGUARD SILEX PLS/3

- Operating temperature: -35/+130°C

Compliant greases:

- TOTAL CALORIS M/3

- FINA BENTEX 5M

- SHELL RETINAX HDX

- MOBIL MOBILGREASE SPECIAL

- FUCHS RENOLIT FLM/2

- BP GREASE LTX/2M

- AGIP GREASE SM/2

- CASTROL MOLY GREASE/2

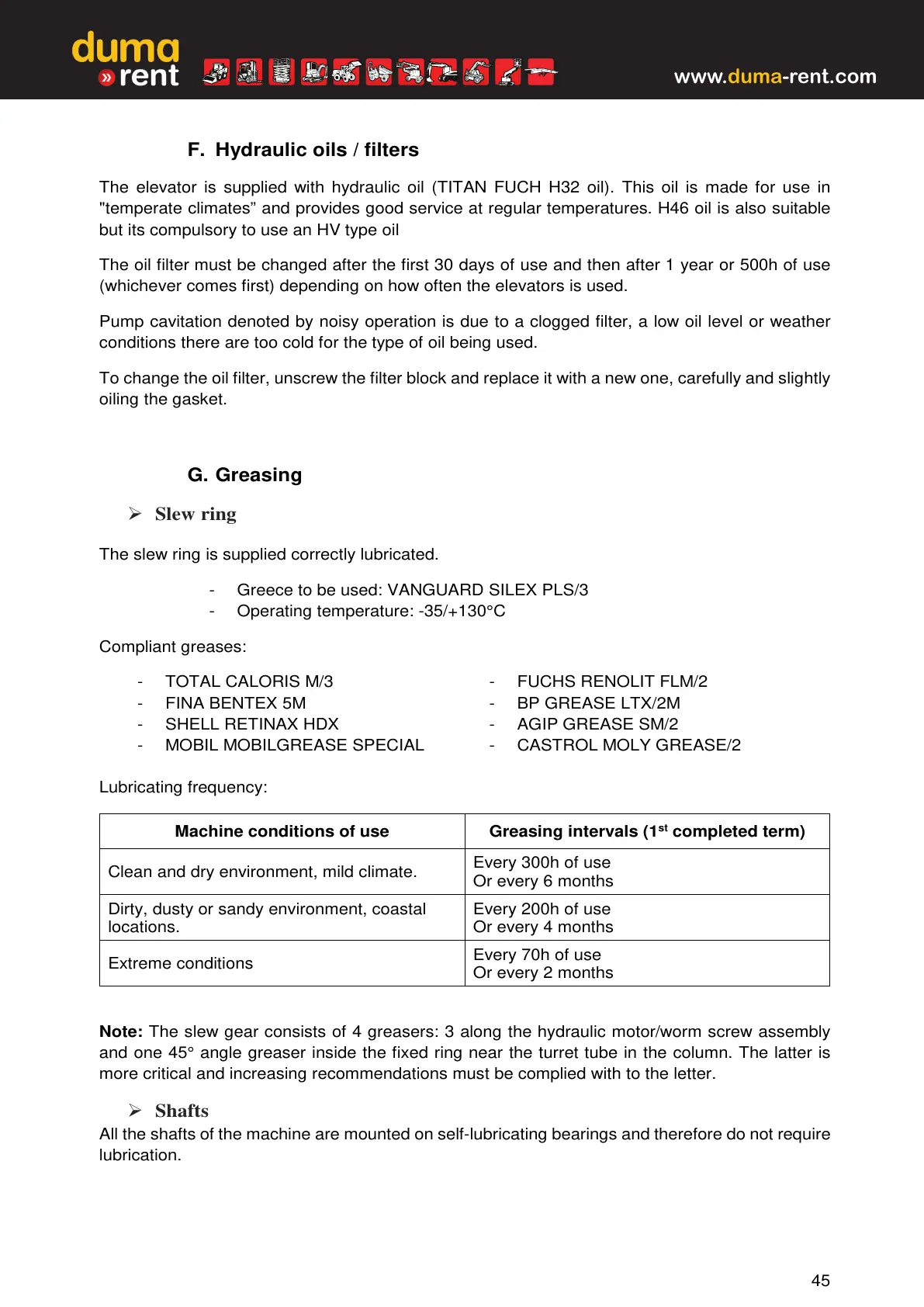

Lubricating frequency:

Machine conditions of use Greasing intervals (1

st

completed term)

Clean and dry environment, mild climate.

Every 300h of use

Or every 6 months

Dirty, dusty or sandy environment, coastal

locations.

Every 200h of use

Or every 4 months

Extreme conditions

Every 70h of use

Or every 2 months

Note: The slew gear consists of 4 greasers: 3 along the hydraulic motor/worm screw assembly

and one 45° angle greaser inside the fixed ring near the turret tube in the column. The latter is

more critical and increasing recommendations must be complied with to the letter.

Shafts

All the shafts of the machine are mounted on self-lubricating bearings and therefore do not require

lubrication.

Loading...

Loading...