5.12

Section 5

Fuel System and Governor

5. Install the bowl gasket, fuel bowl, bowl retainer

gasket, and bowl screw/shut-off solenoid/power

screw, as equipped. Torque to: 5.1-6.2 N·m

(45-55 in. lb.).

High Altitude Operation

When operating the engine at altitudes of 1830 m

(6000 ft.) and above, the main fuel mixture tends to

get overrich. An overrich mixture can cause

conditions such as black, sooty exhaust smoke,

misfiring, loss of speed and power, poor fuel economy,

and poor or slow governor response.

To compensate for the effects of high altitude, a special

high altitude main fuel jet can be installed. High

altitude jets are sold in kits which include the jet and

necessary gaskets. Refer to the parts manual for the

engine being serviced for the correct kit number.

Fuel Shut-Off Solenoid

Some gasoline fueled engines are equipped with the

optional fuel shutoff solenoid which is installed in

place of the bowl retaining screw or main jet (power)

screw, to eliminate backfiring when the engine is shut

down. If backfiring occurs on engines equipped with

this solenoid, check the battery first to insure that it is

not discharged or faulty. A minimum of 7.3 volts D.C.

is required to activate the solenoid. Also check to see

that the ground lead from the carburetor body is

properly connected to the carburetor mounting stud

or the plated (silver) baffle screw. If these check out,

the solenoid should be removed for bench testing.

Remember to shut off fuel and catch any fuel spilling

from the carburetor as the solenoid is removed.

Below is a simple test made with the engine off that

can determine if the solenoid is functioning properly.

Use a separate switched 12 volt power supply to test.

1. Shut off the fuel and remove the solenoid from

the carburetor. When the solenoid is loosened and

removed, gas will leak out of the carburetor. Have

a container ready to catch the fuel.

2. Blow/clean off solenoid using clean, compressed

air.

CAUTION

Do this test away from any fuel/vapors to prevent an

accident.

3. Attach a jumper wire with alligator clips between

the solenoid black ground lead and the ground

lead/location of the switched 12 volt power

supply.

4. With the switched 12 volt power supply "off",

insert a 1/4 male spade terminal into the

terminal end of the red power lead. Connect the

exposed terminal to the positive (+) power

supply lead/connection.

5. Turn "on" the power supply. If the pin of the

solenoid retracts the solenoid is good. Perform

test (switch off-on), a minimum of 6 times to

verify operating performance.

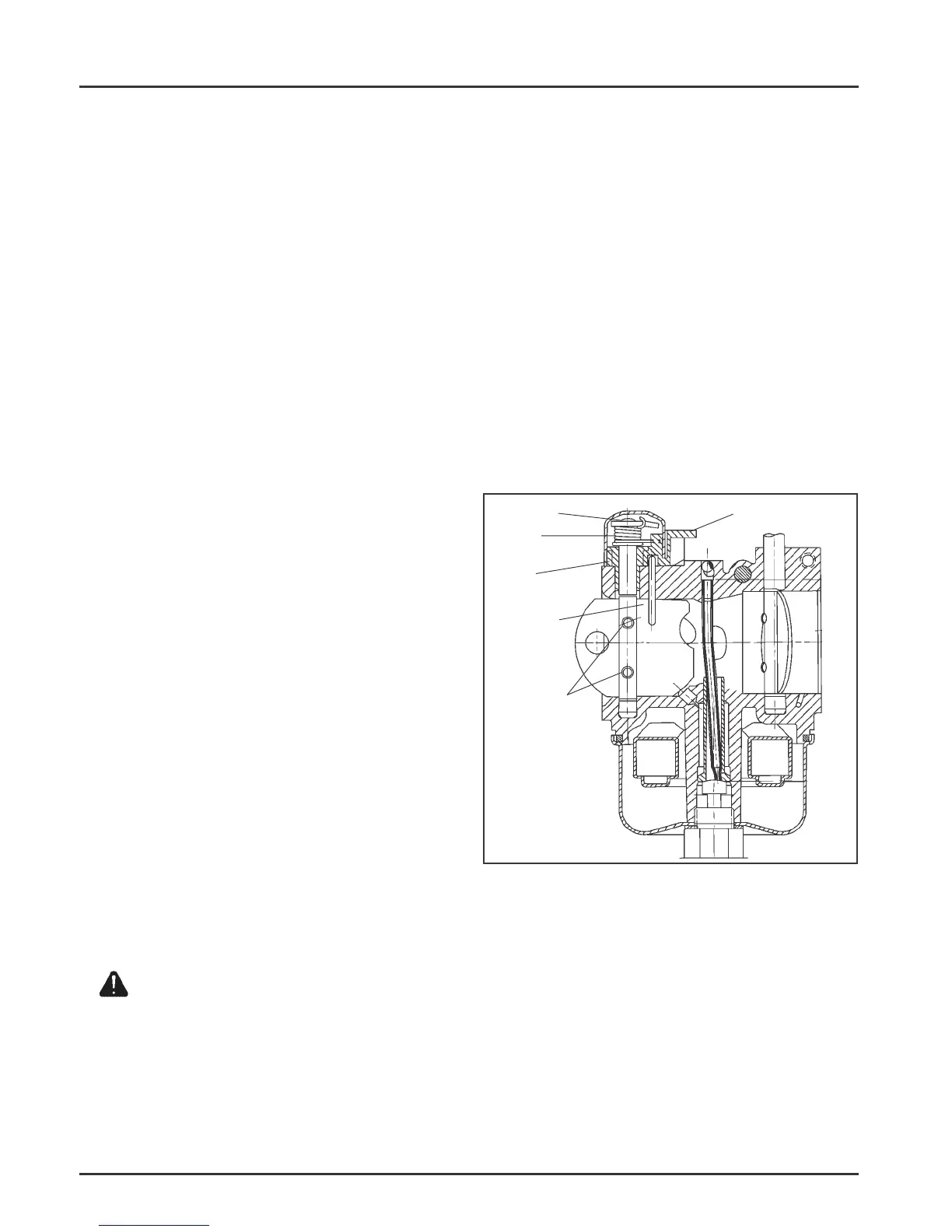

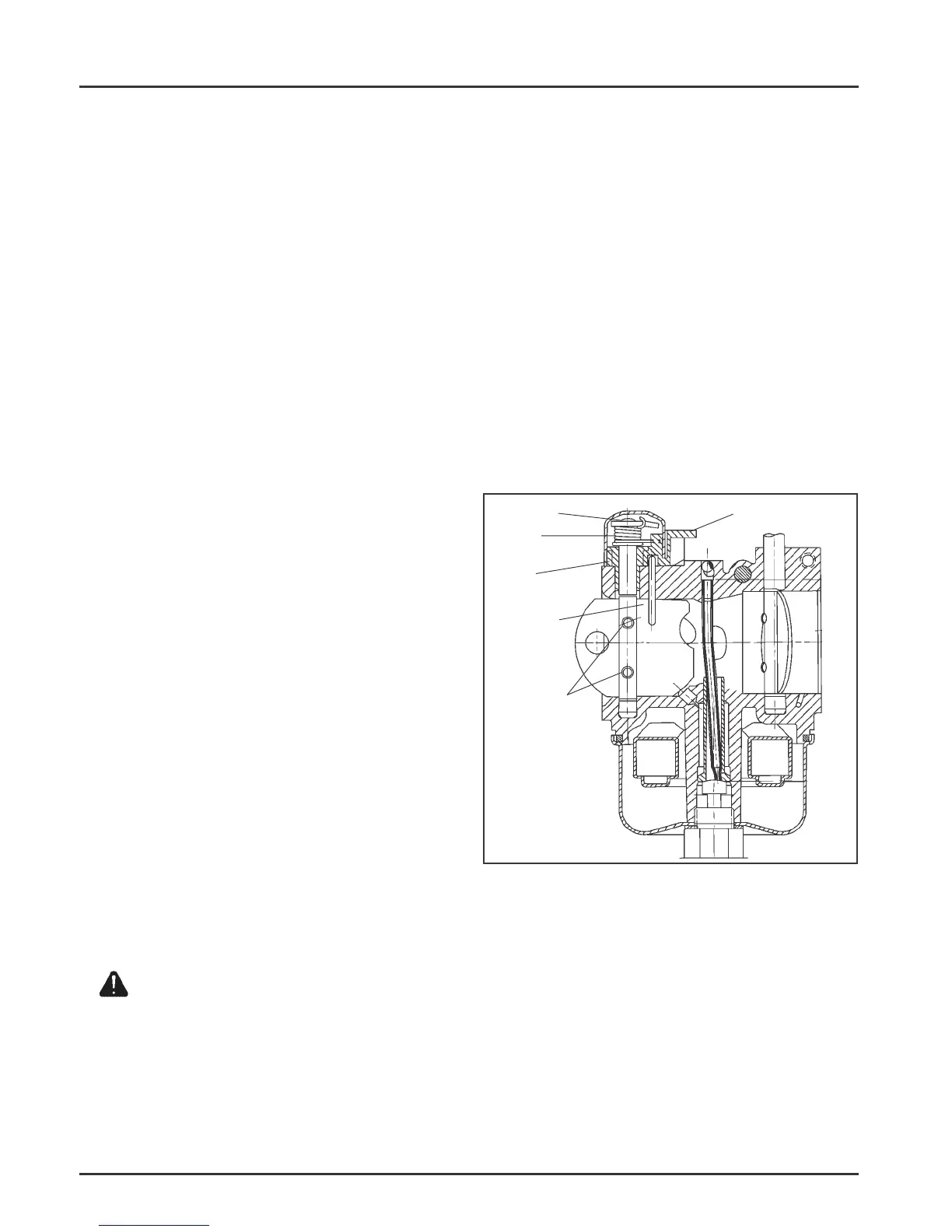

Self-Relieving Choke Service

On carburetors featuring the self-relieving choke, as

shown in cutaway of Figure 5-15, the choke plate is

secured to the choke shaft with two screws. On

carburetors without this feature, the choke plate fits

into a slot in the shaft. Use the following procedure to

replace the self-relieving choke components using

Choke Repair Kit No. 12 757 11 for gasoline

carburetors.

Figure 5-15. Cutaway View Showing Self-Relieving

Choke Carburetor.

Removing Old Parts

1. Remove the black dust cover. This cover snaps on

and off.

2. Remove and discard the two screws fastening

the choke plate to the choke shaft.

3. Remove and discard the choke plate and choke

shaft from the carburetor.

Choke Lever

Dust Cap

Spring

Brass

Bushing

Stop Pin

Choke Valve

Screw

Loading...

Loading...