Oil Pump Assembly (Style B)

Oil pump is mounted inside oil pan. If service is required,

continue with Disassembly, Inspection, and Reassembly.

Disassembly

1. Remove screws.

2. Lift oil pump assembly from oil pan. Remove outer

gerotor gear from oil pan.

3. Ensure ball and spring remain installed in pressure

relief hole of oil pan. If ball and spring fall out of

pressure relief hole, see reassembly for correct

installation.

4. Remove oil pump cover O-ring from groove in oil

pan.

Inspection

Inspect oil pump housing, gear, and rotors for nicks,

burrs, wear, or any visible damage. Inspect oil pump

cover O-ring for cuts, nicks, or any visible damage. If any

parts are worn or damaged, replace oil pump assembly

and/or O-ring. Check oil pickup screen for damage or

restriction, replace if necessary.

Reassembly

1. Lubricate outer gerotor gear with oil. Install outer

gerotor gear through shaft of oil pump, around inner

gerotor gear. Matching molding dots on inner and

outer gerotor gears is not necessary and will not

affect oil pump efciency.

2. Reinstall ball, then spring into pressure relief hole in

oil pan.

3. Reinstall O-ring into groove in oil pan; make sure it is

fully seated in groove.

4. Install oil pump inserting center shaft into

corresponding recess in oil pan. Apply consistent

downward pressure to oil pump cover, compressing

oil pressure relief spring and start screws. Secure oil

pump by torquing screws (in no specic sequence)

to 9.0 N·m (80 in. lb.).

5. After torquing, rotate gear and check for freedom of

movement. Make sure there is no binding. If binding

occurs, loosen screws, reposition pump, retorque

screws and recheck movement.

Remove Camshaft

Remove camshaft and shim (if used).

Inspection and Service

NOTE: To prevent repeat failures, camshaft and

crankshaft should always be replaced as a set.

Check lobes of camshaft for wear or damage. See

Specications for minimum lift tolerance. Inspect

cam gear for badly worn, chipped or missing teeth.

Replacement of camshaft will be necessary if any of

these conditions exist.

Remove Governor Cross Shaft

1. Remove hitch pin and plain washer, or retainer and

nylon washer, from governor cross shaft.

2. Remove cross shaft through inside of crankcase.

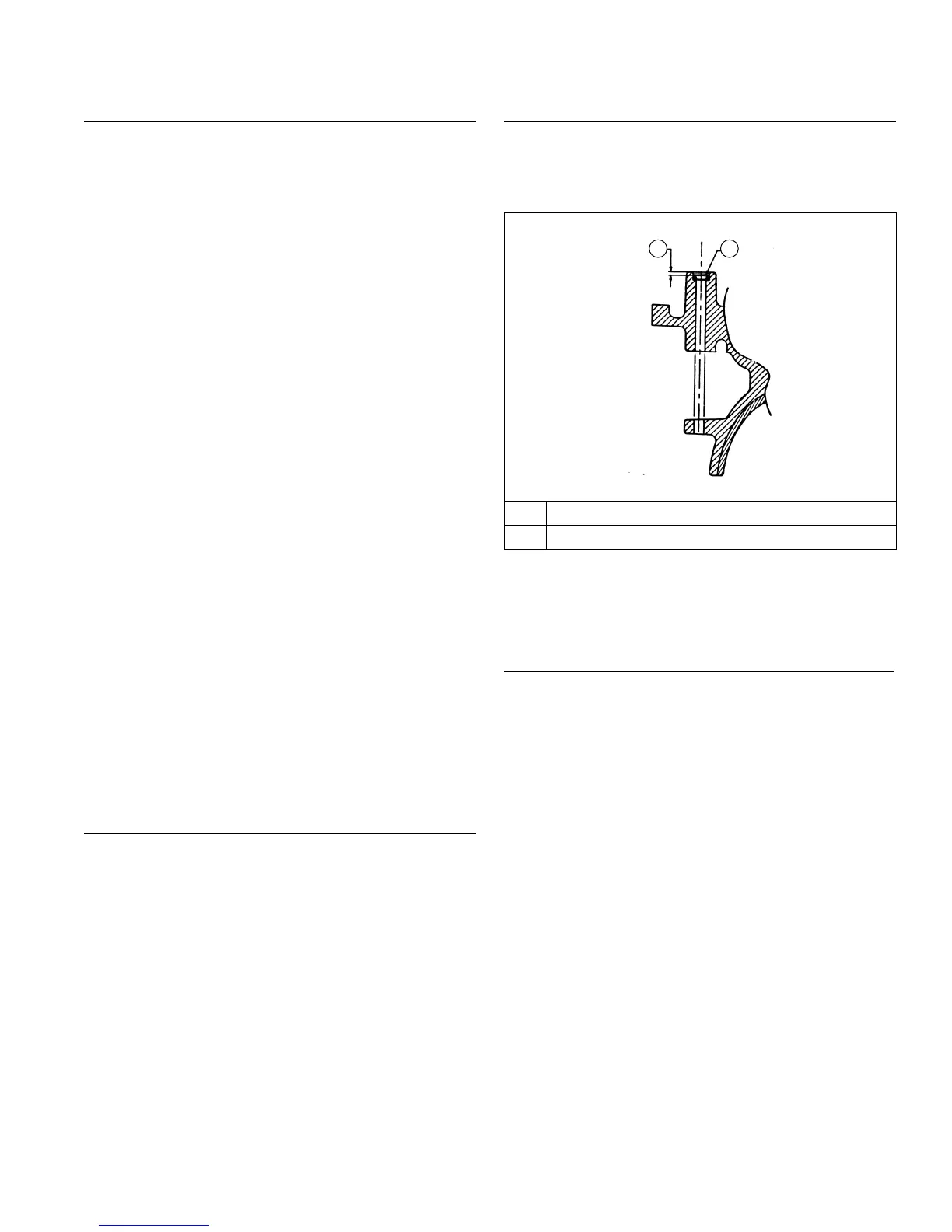

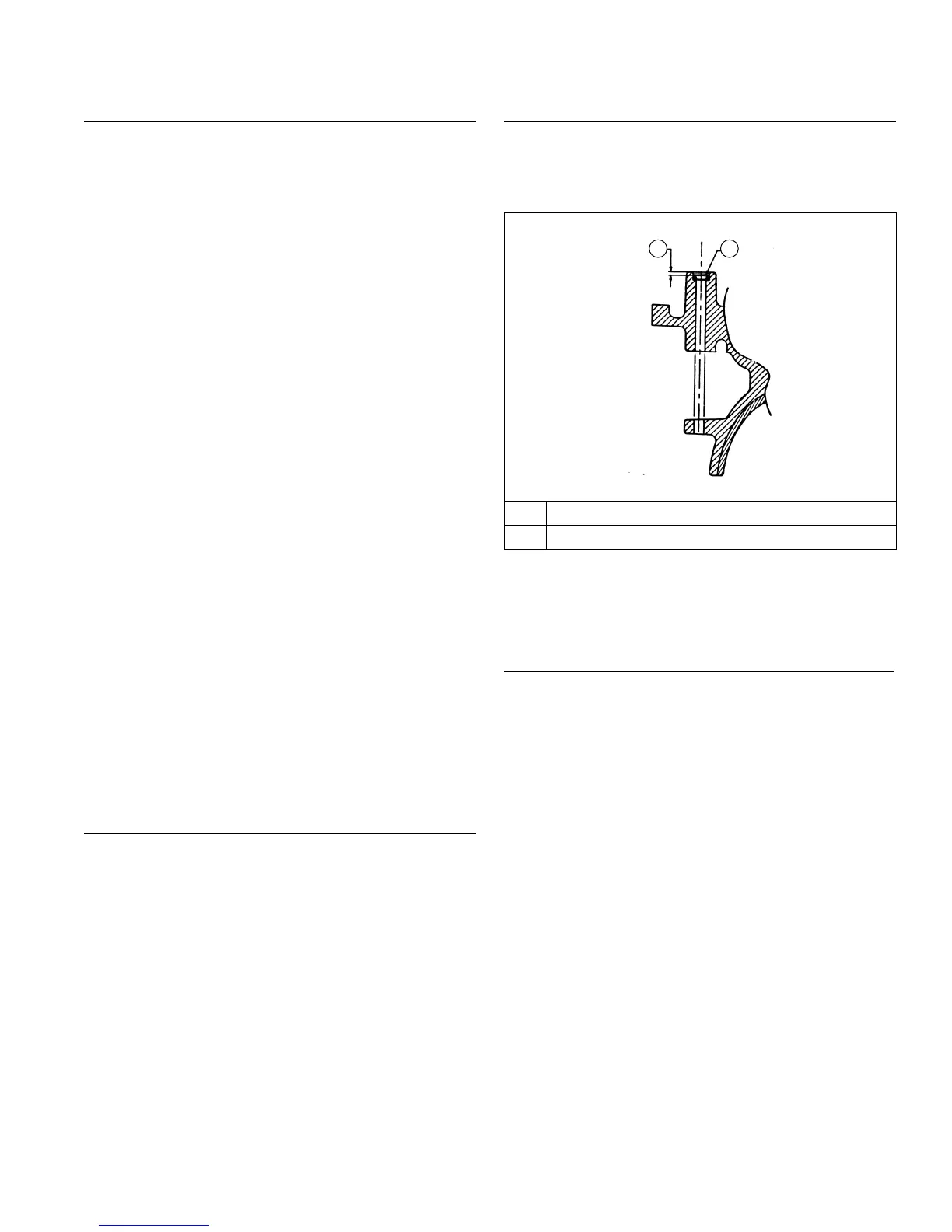

Governor Cross Shaft Oil Seal

A B

A 2.0 mm (0.0787 in.)

B Governor Cross Shaft Seal

If governor cross shaft seal is damaged and/or leaks,

replace it using following procedure.

Remove oil seal from crankcase and replace it with a

new one. Install new seal to depth shown using a seal

installer.

Remove Connecting Rods with Pistons and Rings

NOTE: If a carbon ridge is present at top of either

cylinder bore, use a ridge reamer tool to remove

it before attempting to remove piston.

NOTE: Cylinders are numbered on crankcase. Use

numbers to mark each end cap, connecting rod

and piston for reassembly. Do not mix end caps

and connecting rods.

1. Remove screws securing closest connecting rod end

cap. Remove end cap.

2. Carefully remove connecting rod and piston

assembly from cylinder bore.

3. Repeat above procedure for other connecting rod

and piston assembly.

Disassembly/Inspection and Service

6924 690 07 Rev. H KohlerEngines.com

Loading...

Loading...