Install Supports for Metal Debris Screen

1. If a metal debris screen is used, with threaded individual supports, install a spacer washer on external threads.

Apply blue Loctite

®

242

®

(removable) to threads. Install supports as shown.

2. Tighten supports with a torque wrench to 9.9 N·m (88 in. lb.). Debris screen will be installed to supports after

blower housing is in place.

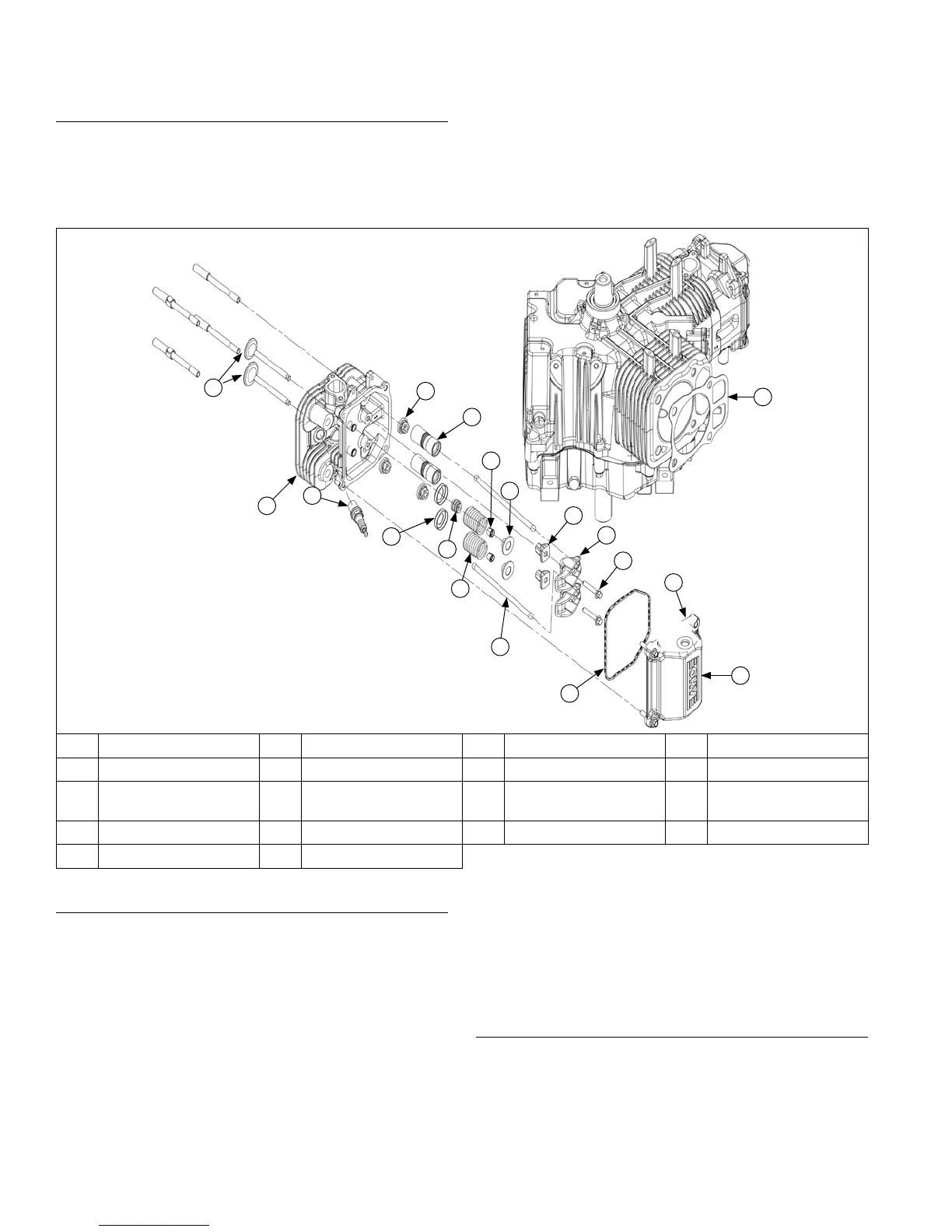

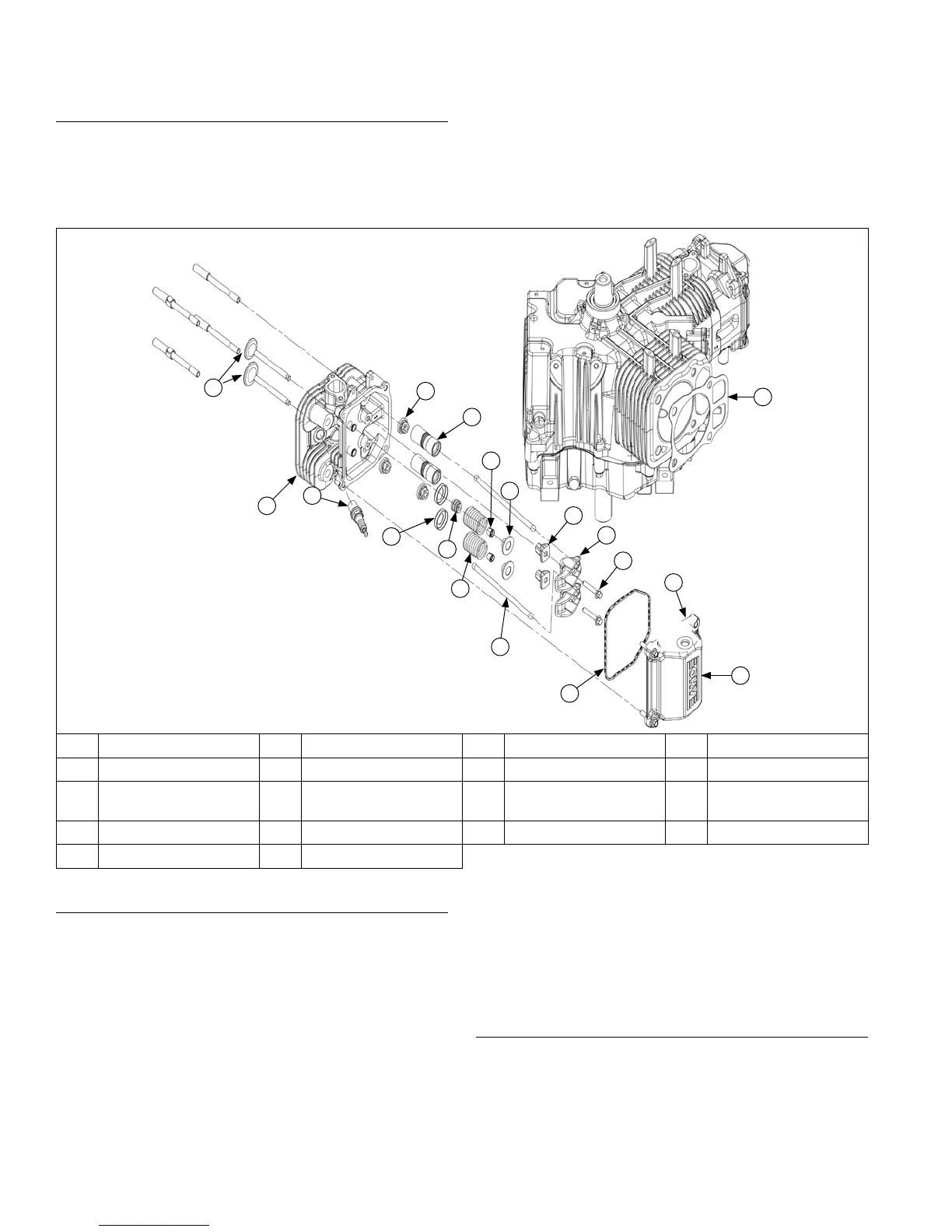

Cylinder Head Components

D

E

Q

K

L

H

B

C

G

F

A

I

J

M

N

O

P

R

A Valves B Cylinder Head C Spark Plug D Nut

E Hydraulic Lifter F Cap G Valve Stem Seal H Valve Spring Keeper

I Valve Spring J

Valve Spring

Retainer

K Rocker Arm Pivot L Push Rod

M Rocker Arm N Screw O Valve Cover O-ring P Grommet

Q Valve Cover R Gasket

Install Hydraulic Lifters

NOTE: Hydraulic lifters should always be installed in

same position as before disassembly. Exhaust

lifters are located on output shaft (oil pan) side

of engine while intake lifters are located on fan

side of engine. Cylinder numbers are embossed

on top of crankcase and each cylinder head.

1. Refer to Disassembly/Inspection and Service for

hydraulic/bleeding lifter procedures.

2. Apply camshaft lubricant to bottom surface of each

lifter. Lubricate hydraulic lifters and lifter bores in

crankcase with engine oil.

3. Note mark or tag identifying hydraulic lifters as either

intake or exhaust and cylinder 1 or cylinder 2. Install

hydraulic lifters into their appropriate locations in

crankcase. Do not use a magnet.

4. If breather reeds and stops were removed from

crankcase, reinstall them at this time and secure

with screw. Torque screw to 4.0 N·m (35 in. lb.).

Valve Stem Seals

These engines use valve stem seals on intake valves

and occasionally on exhaust valves. Use a new seal

whenever valve is removed or if seal is deteriorated or

damaged in any way. Never reuse an old seal.

Reassembly

80

24 690 07 Rev. HKohlerEngines.com

Loading...

Loading...