MACHINE READY FOR ATTACHMENT ATTACHMENTS AND OPTIONS

6-12

ATTACHMENT REMOVAL AND INSTALLATION 6

Attachment Removal 6

1. Lower the attachment to the ground and stop the engine.

2. After stopping the engine, operate each control lever and attachment control pedal to the front and rear, and

left and right 2 or 3 times to the end of its stroke to release the remaining pressure inside the hydraulic circuit.

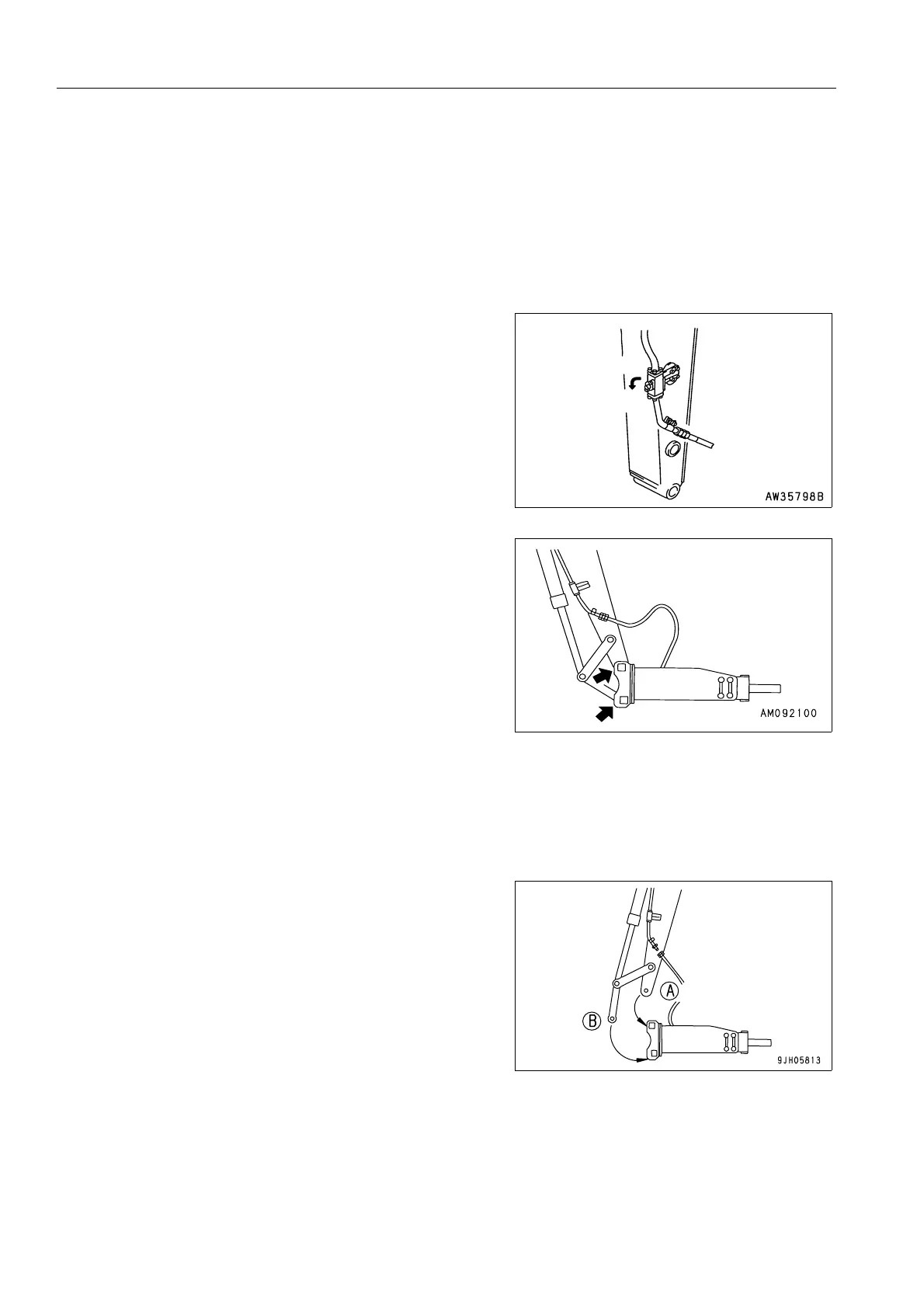

3. After checking that the oil temperature is low, rotate the

rotor of the stop valve (installed to the side face of the arm)

for the inlet and outlet port piping to the Lock position.

4. Remove the hoses on the attachment side. Install the plugs

to the two outlets.

The plugs are used to prevent the attachment from incor-

rect operation caused by mixing in of foreign matter. After

the plugs are correctly installed, store the attachment.

5. Pull out the mounting pins (2 places), remove the attach-

ment, then install the bucket.

For details of the procedure for installing the bucket, see

“BUCKET REPLACEMENT AND INVERSION (3-102)“.

6. After installing the bucket, check the oil level in the hydrau-

lic tank.

Attachment Installation 6

1. Remove the bucket.

For bucket dismounting procedure, see “BUCKET REPLACEMENT AND INVERSION (3-102)“.

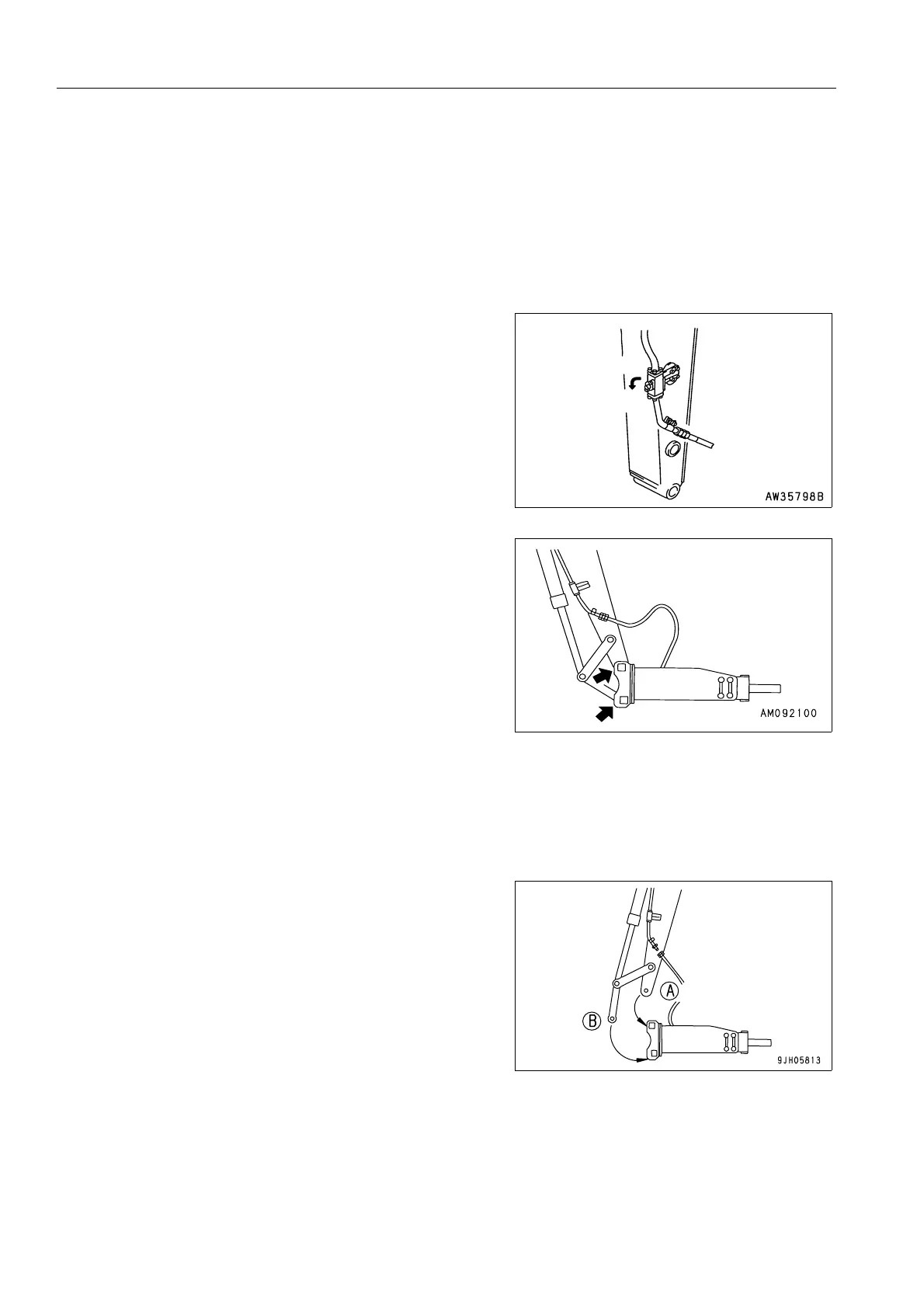

2. Place the attachment in a horizontal position, then install to

the arm with pin (A) and then pin (B).

3. After installing the attachment, stop the engine. Then oper-

ate each control lever and attachment control pedal to the

front and rear, and left and right 2 or 3 times to the end of

its stroke to release the remaining pressure inside the

hydraulic circuit.

4. After confirming low oil temperature, remove the plug from the outlet and inlet port respectively.

Take care that no dust, mud etc. adheres to the hose mouthpiece portions.

If O-ring is damaged, replace it with a new one.

Free

Lock

Loading...

Loading...