2

WALK-AROUND

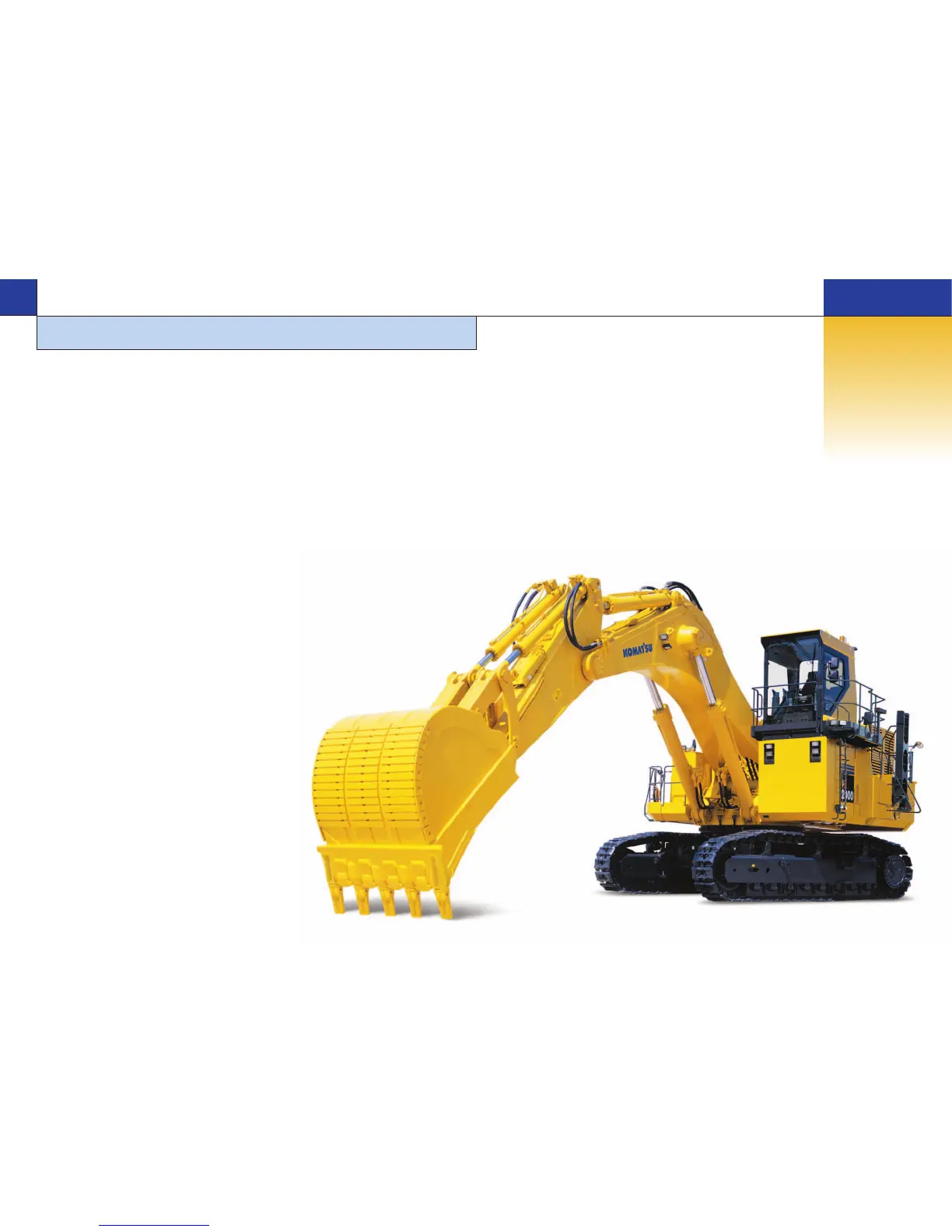

H YDRAULIC E XCAVATOR

HYDRAULIC EXCAVATOR

PC2000-8

PC2000-8

HORSEPOWER

Gross: 728 kW 976 HP @ 1800 rpm

Net: 713 kW 956 HP @ 1800 rpm

OPERATING WEIGHT

Backhoe

200000 – 204120 kg

440,920 – 450,000 lb

Loading shovel

195000 kg

429,900 lb

Photo may include optional equipment.

3

Productivity and Economy

● Fuel Efficient Machine Achieved by Total Power Management and Advanced Hydraulic System

Fuel Consumption at Economy Mode 10% Reduced (compared with PC1800-6)

• Hydraulic power loss reduced with advanced hydraulic system

• On-demand fan speed and engine output control system

• Equipped with electronically controlled variable speed fans

● Powerful and Economical Engine

Komatsu SAA12V140E-3 Engine with an Output of 713 kW (956 HP)

Controlled by Efficient Power Management System

• Auto-deceleration and auto-idling system

• Two work modes; Power and Economy

Ecology

● EPA Tier 2 Emission Certified Komatsu Engine

● New Technology Produces Remarkably Low Environmental Noise

Dynamic Noise 8 dB lower than PC1800-6

• Power module packaging and noise absorbing blades trap noise inside

• 3-D hybrid fan minimizes air turbulence noise

See pages 4, 5.

Easy Repair and Maintenance

Low R&M Cost Sustained by Simplified and Reliable System with Long

Service Life

● Simplified and Durable Structure

• Single engine and PTO drive two Komatsu HPV375+375 pumps

• Simplified travel unit with single motor (each side)

• Reinforced track components

• Long life oil and filters

• Extended life of rubber components achieved by lowering hydraulic oil

temperature

● Power Module Makes Installation and Removal of Components Easier,

and Reduces Overhaul Hours and Cost

● Service Friendly Design

• Maintenance deck surrounding the power module

• Drain ports accessible from the ground level

• Concentration of filters

• Large fuel tank enables 24 hours continuous machine operation

• Auto-greasing system including bucket pins with 200 liter

52.8 U.S.gal grease tank

● VHMS Monitors the Machine Condition and Minimizes Machine

Down Time

See pages 6, 7, 8 and 9.

Operator Comfort

● Newly Designed Mining Shovel Cab Provides Comfortable Operation

• Excellent operational visibility with extended front windshield and large twin wiper

• Extremely low noise and vibration

• Dynamic in-cab noise reduced to the same level as passenger cars

• Rugged OPG top guard integrated into the cab

• Easy-to-see and easy-to-use 7-inch TFT-LCD large monitor

• Comfortable air-suspension seat

• Automatic air conditioner

• Highly pressurized cab

● Bulkhead between Pump Room and Engine

● Emergency Stop Devices

● Interconnected Horn and Flashing Light

See pages 10, 11, 12 and 13.

Loading...

Loading...