4.9 Service procedure

Maintenance Every 250 hours service

WA470-6H – VEAM946100 4-67

Lubricating

NOTE

On jobsites where there is a lot of heavy-duty work, or on job-

sites where operations are carried out continuously for more

than eight hours, reduce the greasing interval and carry out

greasing more frequently.

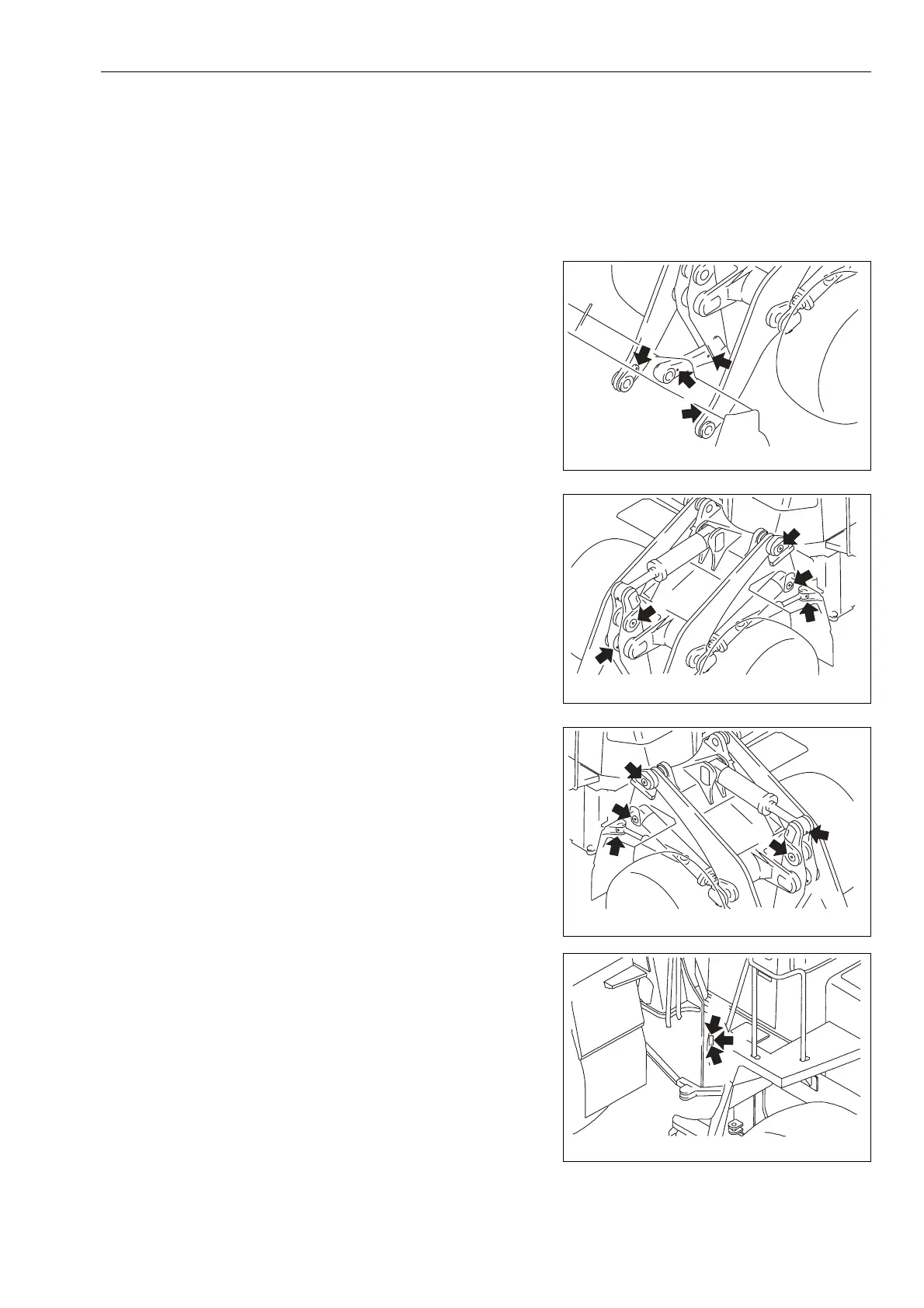

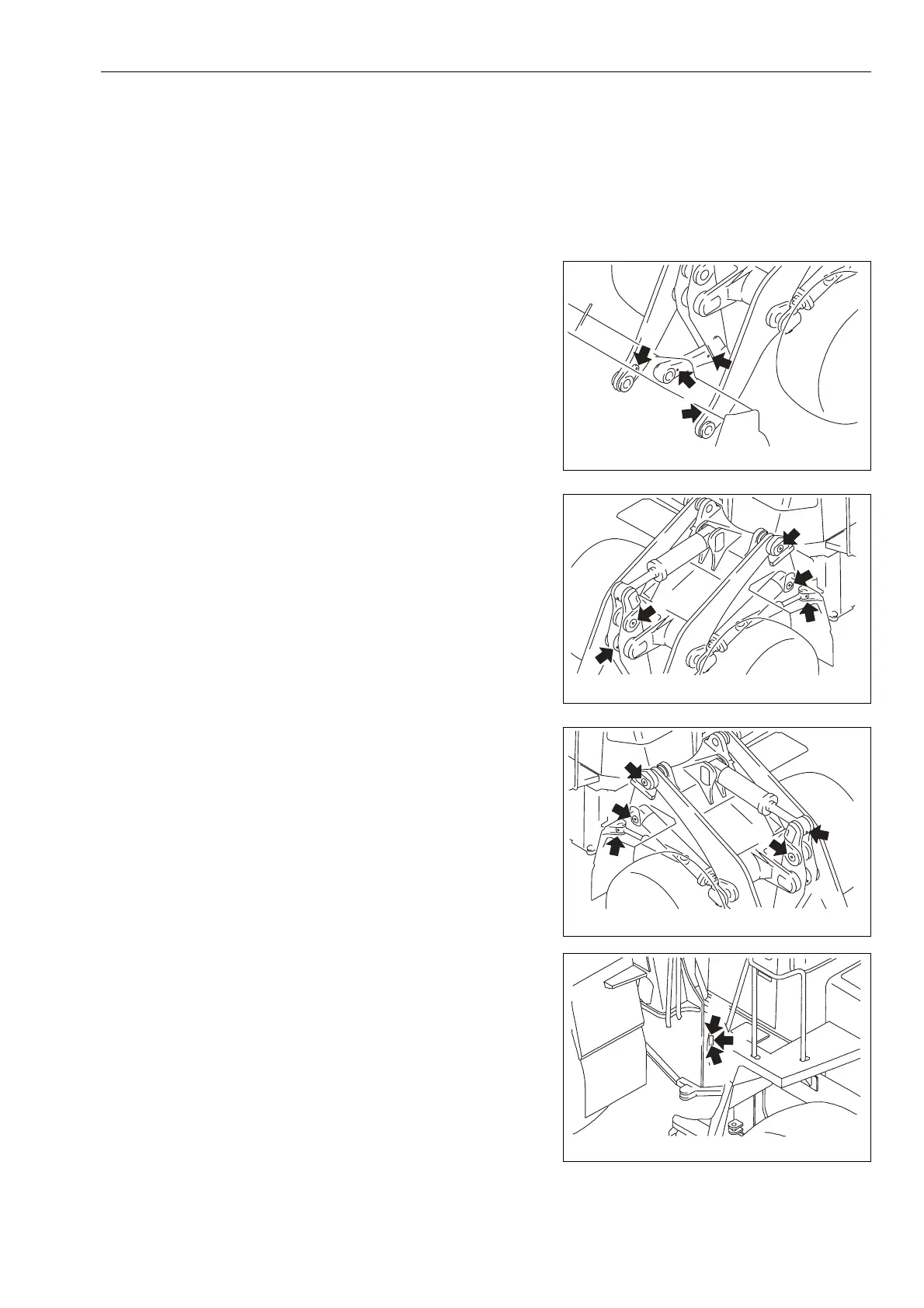

1. Put the work equipment horizontally in contact with the

ground, then stop the engine.

2. Using a grease pump, pump in grease through the grease

fittings marked by the arrows.

3. After greasing, wipe off any old grease that was pushed out.

(1) Bucket pin (2 places)

(2) Bucket link pin (2 places)

(3) Dump cylinder pin (2 places)

(4) Lift cylinder pin (4 places)

(5) Lift arm pivot pin (2 places)

(6) Tilt lever pin (1 place)

(7) Steering cylinder pin (4 places)

GK043091

1

1

2

2

GK043090

6

4

5

4

7

GK043089

5

4

7

4

3

4

GK043088

3

7

7

Loading...

Loading...