Plug the pocket holes

1 Apply glue in the pocket hole and/or to the plug.

2 Insert the plug, letting it protrude 1/16" [2mm] above the workpiece

surface.

3 Allow the glue to dry.

4 Sandtheplugush.

Cut the plugs from the blank

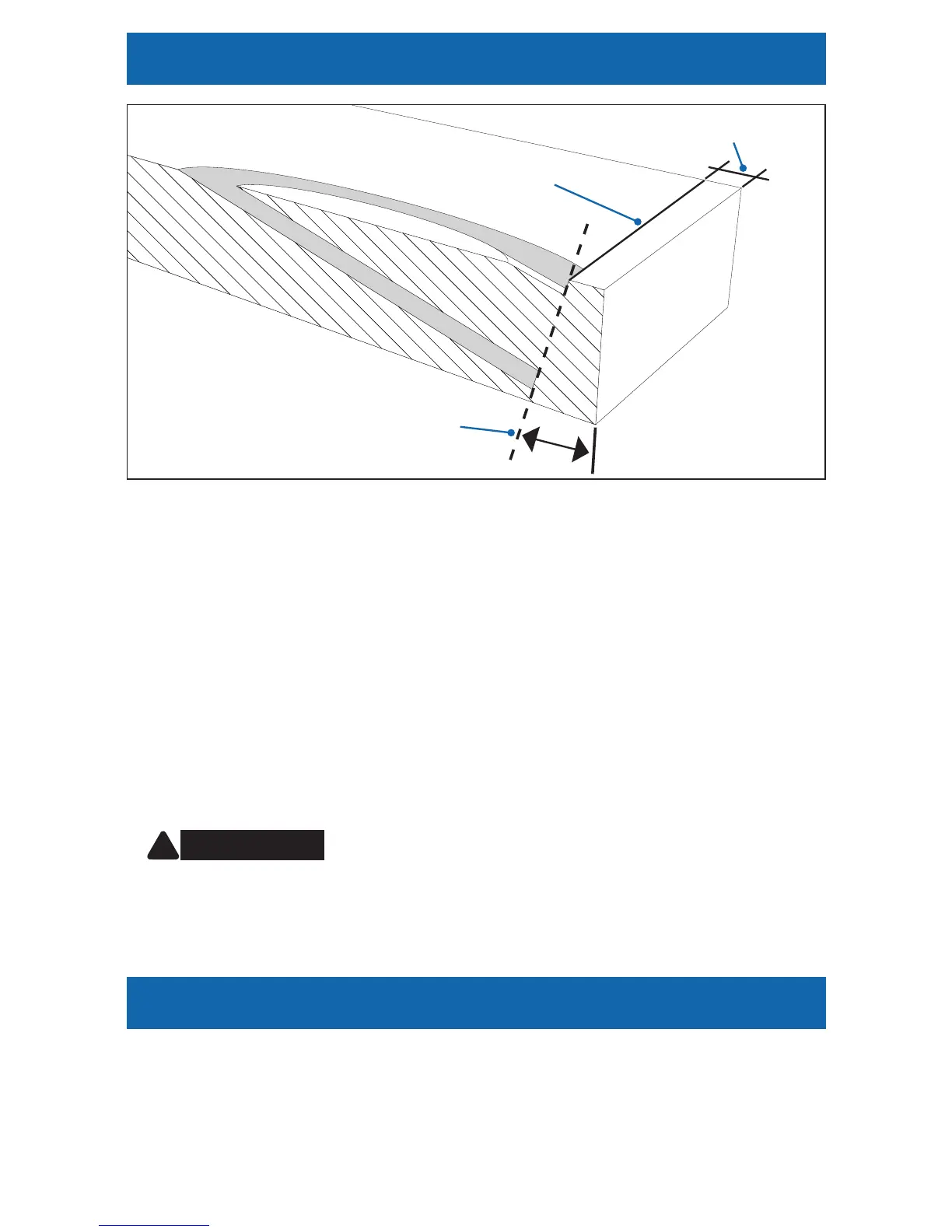

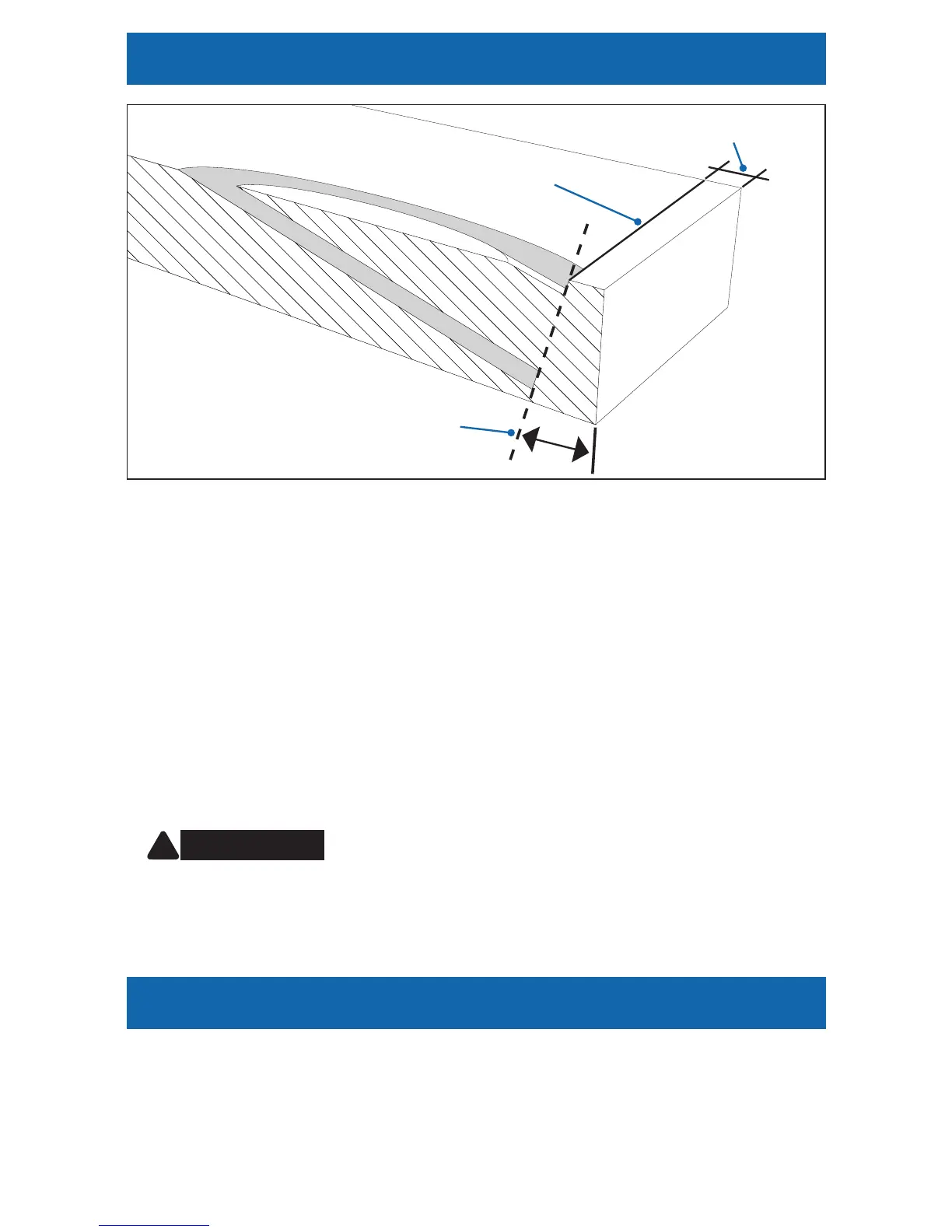

1 Mark a cut line

3

⁄16" [5mm] from the bottom edge of the plug blank.

Note: Plugs cut using this dimension will protrude slightly from the

pockethole,providinganextramarginforachievingthebestt.To

makeshorterplugs,cutslightlyfartherfromtheendoftheblank.

2 Apply a strip of masking tape across the plugs to keep them in

position while cutting.

3 Cut along the line at a 15° angle with a band saw, jig saw,

scrollsaw,multi-purposeoscillatingtool,orne-toothhandsaw.

You also can cut the plugs square to the end of the plug blank and

then sand the end to a 15° angle.

15°

cut angle

cut line

3/16" (5mm)

ATTENTION When plugging pocket holes drilled in ½" to

¾" [13mm to 19mm]-thick material, cut the plugs at the 15°

angle indicated. When plugging pocket holes drilled in material

thicker than ¾" [19mm], you can cut the plugs at 90°.

!

Loading...

Loading...