What to do if high oil temperature trips KTC Air Compressor?

- JJason SmithJul 30, 2025

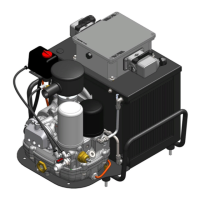

If the high oil temperature limit has tripped, causing your KTC Air Compressor to stop, possible causes include low oil level, excessively high environmental temperature, or a clogged air oil exchanger. You should top up the oil level, ensure the exchanger is clean, and verify that the electric fan is working correctly. Also, check the environmental temperature parameters. If the issue persists, the temperature probe may have failed and require replacement.