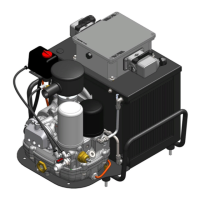

What to do if motor thermal trip causes my KTC COMPACK 2 ECO to stop?

- CCarl VaughnAug 13, 2025

If the motor thermal trip causes the KTC Air Compressor to stop due to the main motor being overloaded, several factors could be at play. First, verify the correct calibration of the thermal protection. Ensure the electric power supply is correct and that power cables are firmly secured to the terminal and not damaged. Also, check that the main motor ventilation is free of any fouling or foreign objects. If the oil separator differential pressure exceeds 1.0 bar, causing high system absorption, have qualified personnel check the unit.