Do you have a question about the Kubota WG972-E2 and is the answer not in the manual?

Information on general precautions, check and maintenance, and special tools.

Information on the construction and function of the engine.

Covers troubleshooting, specifications, checking, adjusting, and assembly procedures.

Explanation of safety symbols and their meanings for hazard identification.

Pre-service checks and safety preparations for maintenance.

Safety precautions to be followed before and during engine starting.

General safety precautions to be observed while working on the machine.

Precautions to prevent fires and explosions related to fuel and battery.

Importance of ventilation to avoid carbon monoxide poisoning.

Precautions for handling battery electrolyte to prevent acid burns.

Guidelines for environmentally safe disposal of oils and other fluids.

Recommendations for emergency preparedness, including first aid and contact info.

Specifications for air cleaner, inlet pipe, and exhaust back pressure.

Application of altitude kits for EPA and CARB emission compliance.

Requirement for using a genuine KUBOTA LPG regulator kit.

Recommended fuel specifications for LPG engines.

Specification for LPG vapor hose length to ensure emissions compliance.

Identification of engine model and serial number for service.

Designation of cylinder numbers for KUBOTA gasoline/LPG engines.

Important precautions during disassembly, service, and reassembly.

Schedule for regular engine inspections and maintenance intervals.

Daily checks for engine oil level and other critical points.

Procedure for checking and refilling engine coolant levels.

Inspection of the air cleaner element for dirt and damage.

Maintenance checks and oil change after the first 50 hours.

Maintenance checks and procedures to be performed every 100 operating hours.

Procedure for removing, checking, and replacing the spark plug.

Inspection of hot water hoses for damage or leaks.

Inspection of vacuum lock hoses for damage or leaks.

Procedure for draining accumulated tar from the vaporizer.

Procedure for checking and adjusting valve clearance when engine is cold.

Maintenance checks and component replacements performed annually.

Procedure for removing and replacing the air cleaner element.

Replacing the fuel filter and fuel hose for gasoline fuel system.

Procedure for draining and cleaning the gasoline fuel tank.

Procedure for cleaning the engine's water jacket and radiator interior.

Information on antifreeze types, mixing ratios, and properties.

Maintenance checks and component replacements performed every two years.

Procedure for replacing the intake hose and clamps.

Procedure for replacing the LPG fuel hose and clamps.

Procedure for replacing hot water hoses connected to the vaporizer.

Procedure for replacing vacuum lock hoses.

Checking the primary chamber pressure of the LPG vaporizer.

Checking the air tightness of the secondary chamber of the LPG vaporizer.

Procedure for checking the operation of the vacuum lock system.

Procedure for replacing radiator hoses and clamp bands.

List of special tools required for engine maintenance and servicing.

Description and application of a timing light for ignition timing adjustment.

Description and application of a compression tester for engine diagnostics.

Description and application of an oil pressure tester.

Description and application of a radiator tester for pressure checks.

Description and application of a pressure gauge for vaporizer checks.

Tool used for pressing out and fitting valve guides.

Tools used for pressing out and fitting bushings.

Tool used for securing the flywheel.

Tool for pressing out and fitting the crankshaft bearing 1.

Tool used for pressing in the valve stem seal.

Tool and hardware requirements for servicing the electronic governor.

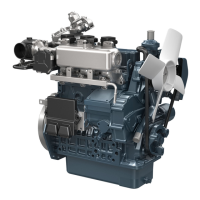

Overview of the engine's features, technology, and benefits.

Description of the cylinder block's high durability tunnel-type construction.

Description of the half-floating head cover and its noise reduction function.

Description of the cylinder head, including intake/exhaust ports and combustion system.

Description of the crankshaft, its oil passages, and bearing support.

Details on pistons, piston rings, oil rings, and piston skirt coatings.

Description of the oil pan and its contribution to engine height.

Description of the connecting rod and its bearings.

Description of the camshaft, its material, and wear resistance.

Description of the fuel camshaft, including governor components.

Description of the rocker arm assembly components and function.

Description of inlet and exhaust valves, guides, and related parts.

Description of the flywheel, its function, and timing marks.

Description of the closed breather system for blow-by gas management.

Overview of the lubricating system's components and oil flow path.

Description of the trochoid oil pump's operation and construction.

Description of the relief valve's function in protecting the lubricating system.

Description of the oil filter cartridge and its bypass valve function.

Description of the oil pressure switch and its role in the warning system.

Overview of the cooling system's components and coolant flow.

Description of cooling fins around the oil passage for heat dissipation.

Description of the water pump's operation and mechanical seal.

Description of the wax pellet type thermostat and its temperature control.

Description of the radiator core, tubes, and fins for heat exchange.

Description of the pressure type radiator cap and its valves.

Description of the vaporizer's function in converting liquid LPG to gas.

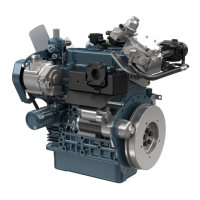

Overview of fuel systems for gasoline (WG972-E2) and dual fuel (DF972-E2).

Detailed description of the WG972-E2 carburetor's systems and operation.

Description of the DF972-E2 carburetor for gasoline and LPG fuels.

Detailed description of the DF972-E2 vaporizer's chambers and operation.

Description of the centrifugal ball mechanical governor's function.

Description of the inlet manifold and its role in mixture heating.

Description of the gasoline fuel filter's construction and function.

Description of the electromagnetic fuel feed pump for gasoline.

Explanation of the digital ignition system's components and operation.

Description of the electromagnetic drive starter system and its operation.

Description of the charging system, alternator, and regulator.

Description of the solenoids used in the fuel system for fuel control.

Description of the electronic governor, integrating actuator and software.

Troubleshooting guide for gasoline fuel system related issues.

Troubleshooting guide for LPG fuel system related issues.

Troubleshooting guide for electronic governor malfunctions.

Servicing specifications for engine body components like clearances and pressures.

Servicing specifications for the lubricating system components.

Servicing specifications for the cooling system components.

Servicing specifications for the ignition system components.

Servicing specifications for electrical system components.

Servicing specifications for the electronic governor system.

Torque values for special use screws, bolts, and nuts.

Torque values for general use screws, bolts, and nuts.

Procedures for checking and adjusting engine components.

Checking engine body parameters like compression and top clearance.

Checking engine oil pressure and fan belt tension.

Checking fan belt tension and thermostat valve opening temperature.

Procedures for adjusting governor and engine speed.

Ignition system timing checks and pick-up sensor resistance.

Starter motor tests, magnet switch continuity, and dynamo output.

Procedures for draining coolant, engine oil, and removing external components.

Removing alternator, starter, fuel line, LPG hose, and water hose.

Adjusting governor lever and throttle lever for electronic governor.

Removing ignition coil, spark plug, cylinder head cover, and valves.

Removing speed control plate, fan pulley, gear case, water pump, idle gear, and camshaft.

Removing connecting rod caps and pistons.

Checking cylinder head surface flatness and flaws.

Checking gear backlash, push rod alignment, and tappet clearance.

Measuring piston pin bore and oil clearance, replacing small end bushings.

Checking crankshaft side clearance and alignment.

Measuring cylinder wear and correcting cylinders.

Measuring oil pump clearances between rotors and cover.

Inspecting starter components: overrunning clutch, commutator, brushes.