ENGINE

L3540-II, L4240-II, L5040-II, L5240-II, L5740-II , WSM

1-S69

Oil Clearance between Crankshaft Journal and Crankshaft

Bearing 1

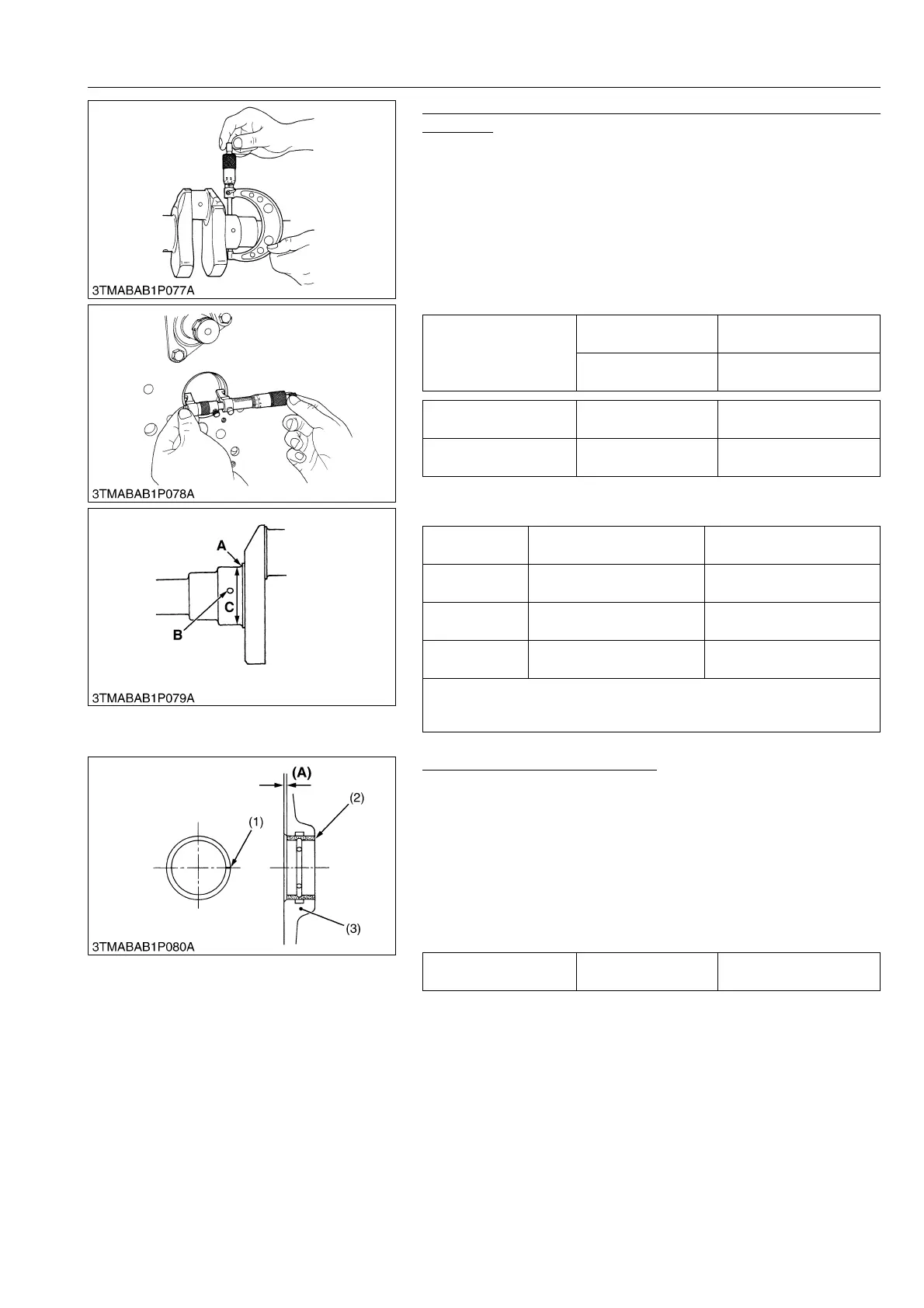

1. Measure the O.D. of the crankshaft journal with an outside

micrometer.

2. Measure the I.D. of the crankshaft bearing 1 with an inside

micrometer, and calculate oil clearance.

3. If the clearance exceeds the allowable limit, replace the

crankshaft bearing 1.

4. If the same size bearing is useless because of the crankshaft

journal wear, replace it with an undersize one referring to the

table and figure.

(Reference)

• Undersize dimensions of crankshaft journal

9Y1211167ENS0089US0

Replacing Crankshaft Bearing 1

(When removing)

1. Press out the used crankshaft bearing 1 using a crankshaft

bearing 1 replacing tool.

(When installing)

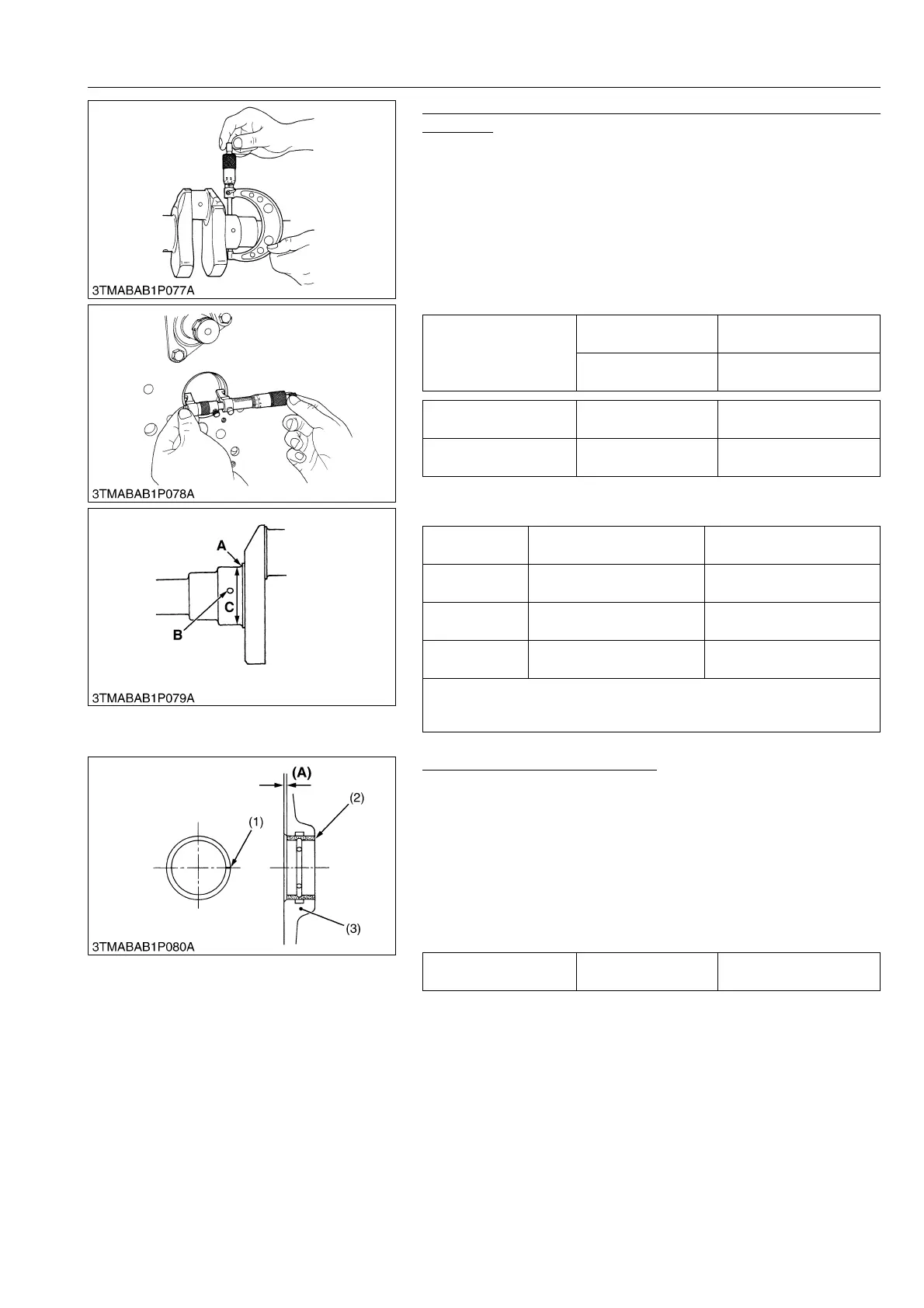

1. Clean a new crankshaft bearing 1 and crankshaft journal bore,

and apply engine oil to them.

2. Using a crankshaft bearing 1 replacing tool, press in a new

bearing 1 (2) so that its seam (1) directs toward the exhaust

manifold side.

9Y1211167ENS0090US0

Oil clearance between

crankshaft journal and

crankshaft bearing 1

Factory specification

0.0400 to 0.118 mm

0.00158 to 0.00464 in.

Allowable limit

0.20 mm

0.0079 in.

Crankshaft journal O.D. Factory specification

59.921 to 59.940 mm

2.3591 to 2.3598 in.

Crankshaft bearing 1 I.D. Factory specification

59.980 to 60.039 mm

2.3615 to 2.3637 in.

Undersize

0.20 mm

0.0079 in.

0.40 mm

0.016 in.

Dimension A

2.80 to 3.20 mm radius

0.111 to 0.125 in. radius

2.80 to 3.20 mm radius

0.111 to 0.125 in. radius

*Dimension B

1.00 to 1.50 mm relief

0.0394 to 0.0590 in. relief

1.00 to 1.50 mm relief

0.0394 to 0.0590 in. relief

Dimension C

59.721 to 59.740 mm dia.

2.3513 to 2.3519 in. dia.

59.521 to 59.540 mm dia.

2.3433 to 2.3441 in. dia.

The crankshaft journal must be fine-finished to higher than Rmax = 0.4S

*Holes to be de-burred and edges rounded with 1.0 to 1.5 mm

(0.0394 to 0.0591 in.) relief.

Dimension (A) Factory specification

4.20 to 4.50 mm

0.166 to 0.177 in.

(1) Seam

(2) Crankshaft Bearing 1

(3) Cylinder Block

Loading...

Loading...