This document is the Operator's Manual for the Landworks Electric Powered Hydraulic Log Splitter, model REV 1.2. It provides comprehensive information on the device's function, technical specifications, safe operation, assembly, and maintenance.

Function Description

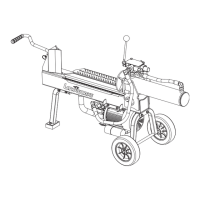

The Landworks Electric Powered Hydraulic Log Splitter is designed to split wood logs using hydraulic force. It converts hydraulic pressure into linear force to drive a splitting wedge through logs. The device is intended solely for splitting wood and should not be used for other purposes unless specific attachments and instructions are provided by the manufacturer. It operates with an electric motor and a hydraulic system, including a pump, cylinder, and control valve, to achieve its splitting action. The log splitter is portable, featuring wheels and a handle for easy movement around a work site.

Important Technical Specifications

- Maximum Exerted Splitting Force: 14 (US tons)

- Electromotor Specifications: 120V, 60Hz, 15A, 1700RPM

- Starter Type: Electric Start

- Cycle Time: 16.5 seconds

- Gear Pump: 10GPM / 38LPM

- Control Valve: Detent (auto-return)

- Hydraulic Cylinder Stroke Length: 16 inches

- Max Log Length: 20.5 inches

- Max Log Diameter: 16 inches

- Hydraulic Fluid Type: AW32, AW46

- Hydraulic Fluid Tank Capacity: 2.1 Gallons (8 Liters)

- Wheel Diameter: 8 inches

- Wire Length: 70.9 inches

- Net Weight: 126 pounds

- Overall Dimensions (L x W x H) (Assembled): 47.09" x 14.02" x 33.98"

Usage Features

The log splitter is designed for ease of use and portability, but emphasizes strict adherence to safety guidelines.

- Electric Start: Simplifies the starting process of the electromotor.

- Auto-Return Control Valve: The detent control valve automatically returns, enhancing operational efficiency.

- Portability: Equipped with 8-inch wheels and a handle, allowing for manual transport around the work site. It is explicitly stated that the product is not intended to be towed by a vehicle, and any modification for such use will void warranties.

- Single-Person Operation: Only one person should operate the log splitter and load logs, ensuring clear communication and reducing accident risk.

- Log Orientation: Logs must be split with the grain, end to end. Splitting perpendicular to the grain is prohibited.

- Log Loading: Users are instructed to hold logs on the sides when loading, keeping hands and feet clear of the cylinder, wedge, and partially split logs.

- Operating Environment: The log splitter must be operated on a flat, level surface. Operating on an incline is prohibited. Support legs should be secure, and tires blocked to prevent unintended movement.

- Hydraulic System Purging: Before first use, or if motion is erratic, the hydraulic system needs to be purged of air by extending and retracting the cylinder multiple times until motion is smooth and continuous.

- Hydraulic Fluid: The manual specifies the type of hydraulic fluid (AW32, AW46) and the capacity (2.1 gallons). It also notes that hydraulic oil is not included in the package for safety reasons and must be added before first use. Dexron III transmission fluid can be used if outdoor temperatures are below 32°F.

Maintenance Features

Regular maintenance is crucial for the safe and efficient operation and longevity of the log splitter.

- Power Disconnection: Always shut off the power source before performing any repairs or adjustments, unless specifically recommended by the manufacturer.

- Debris Removal: Clear debris from movable parts only when the power source is shut off.

- Fastener Checks: Periodically check all nuts and bolts to ensure they are tight and secure, as electromotor vibration can loosen them over time.

- Hydraulic System Inspection: Regularly inspect the hydraulic system for possible leaks. Leaks can be detected by passing cardboard or wood over suspected areas, looking for discoloration. Never check for leaks with bare hands while the system is pressurized due to the risk of skin injection injury.

- Hydraulic Oil Level Check: The hydraulic oil level should be checked using the dipstick. The dipstick should be inserted into the fill neck until it stops, then removed to read the level; it should not be threaded in when checking.

- Hydraulic Oil Addition: If the hydraulic oil level is low or cylinder thrust is insufficient, hydraulic oil should be added. The manual provides a specific procedure for adding oil, including ensuring the log splitter is on a level surface, removing the dipstick, adding the specified amount of oil, checking the level, tightening the dipstick, starting the electromotor, purging air from the system, and then shutting off the electromotor.

- Cooling Vents: Do not allow any material to block the cooling vents of the electromotor.

- Storage: When not in use, the log splitter should be covered with a tarp or stored in a shed to protect it from excessive moisture, dust, or dirt.

- Troubleshooting Guide: The manual includes a troubleshooting section to help diagnose and resolve common issues such as the electromotor not starting, running loudly, slow or erratic wedge movement, oil leaks, and the wedge not extending or retracting. This section provides potential causes and corresponding solutions, often recommending checking oil levels, purging air, clearing debris, or contacting customer service.